Airlift air stirring multi-sublayer circulating extraction device and method

An air stirring and extraction device technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of lack of uniform mixing, insufficient power, and inability to circulate, etc., and achieve the effect of meeting industrial mass production, low power consumption, and low speed requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

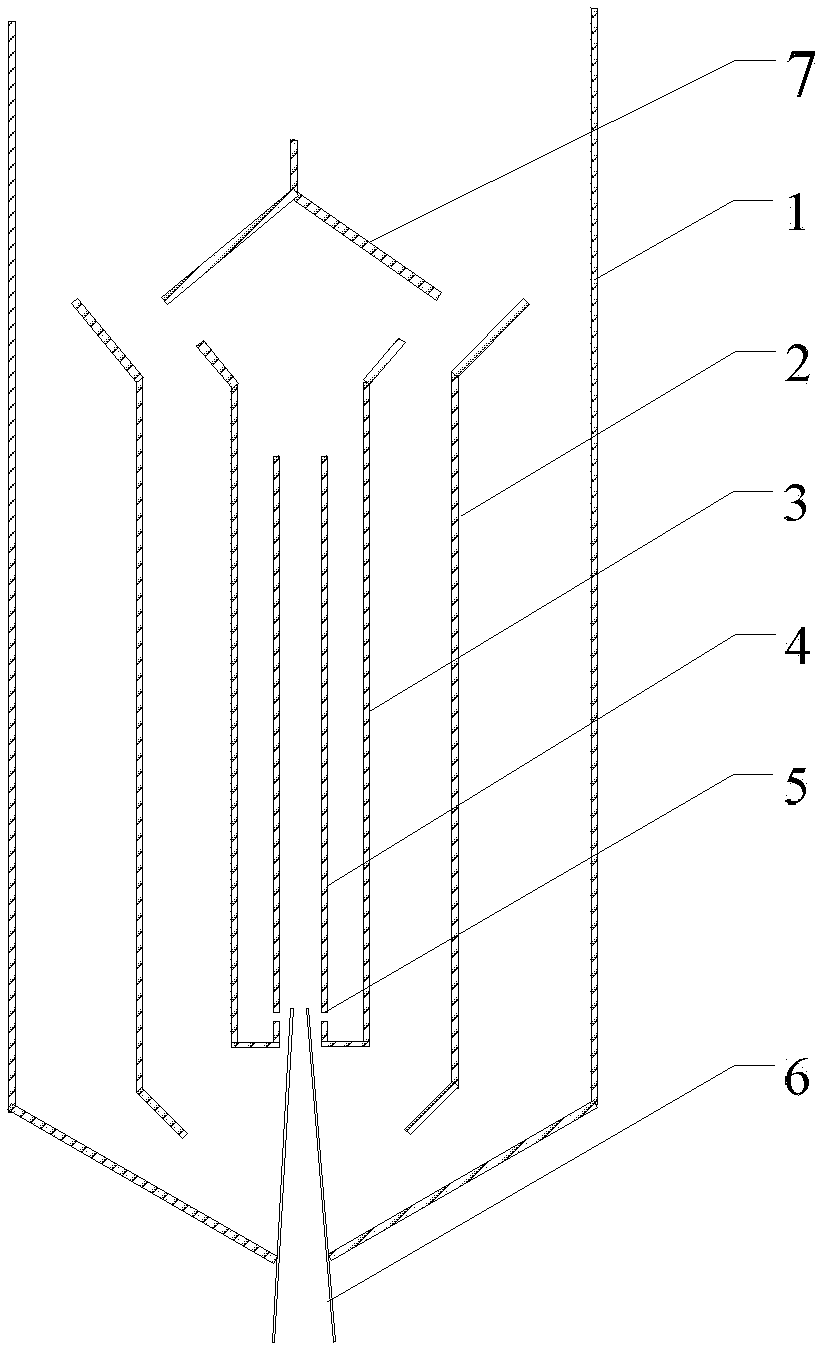

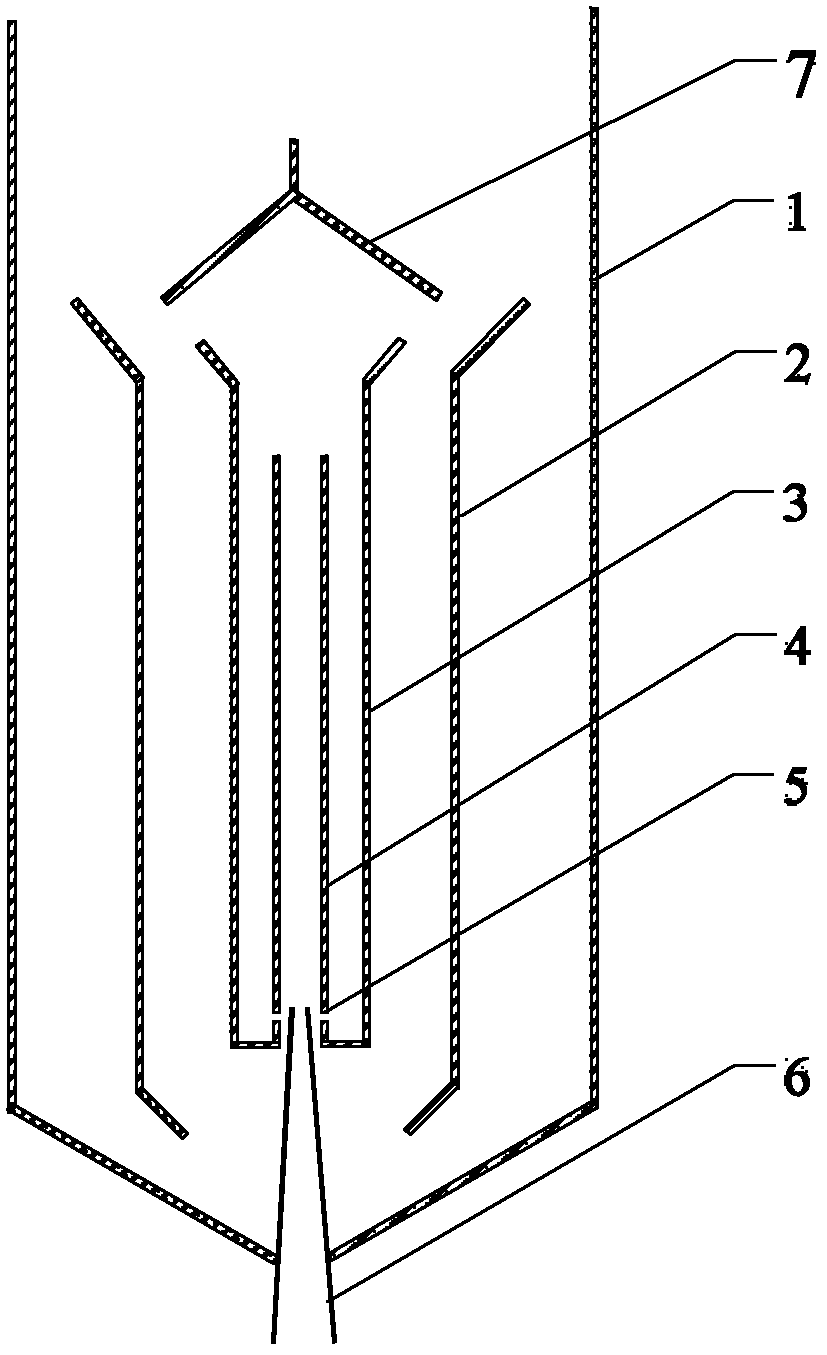

[0033] An air-lift air-stirred multi-layer circulation extraction device, such as figure 1As shown, it includes an outer tube 1 , an outer central tube 3 and an inner central tube 4 , and an inner tube 2 is installed between the outer tube 1 and the outer central tube 3 . An air intake pipe 6 is provided at the bottom of the outer pipe 1; the air intake pipe 6 leads into the inner central pipe 4. The tubes are connected by three support plates to maintain proper spacing between the tubes. The outer central pipe 3 is connected with the lower end of the inner central pipe 4 with a ring seal, and the inner central pipe 4 is provided with a plurality of air inlets 6 at a certain height from its bottom. An arc-shaped baffle 7 is arranged on the top of the inner central tube 4 and the outer central tube 3 , and its diameter is slightly larger than that of the outer central tube 3 .

Embodiment 2

[0035] An air-lift air-stirring multi-layer circulation extraction device, comprising an outer tube 1, an outer central tube 3 and an inner central tube 4, the outer tube 1 is equipped with a thinner inner tube 2, and the inner tube 2 is equipped with a thinner inner tube The outer center tube 3 is equipped with a thinner inner center tube 4 inside the outer center tube 3 . An air intake pipe 6 is provided at the bottom of the outer pipe 1; the air intake pipe 6 leads into the inner central pipe 4. The tubes are connected by five support plates to maintain proper spacing between the tubes. The outer central pipe 3 is connected with the lower end of the inner central pipe 4 with a ring seal, and the inner central pipe 4 is provided with a plurality of air inlets 6 at a certain height from its bottom. An arc-shaped baffle 7 is arranged on the top of the inner central tube 4 and the outer central tube 3 , and its diameter is slightly larger than that of the outer central tube 3 ...

Embodiment 3

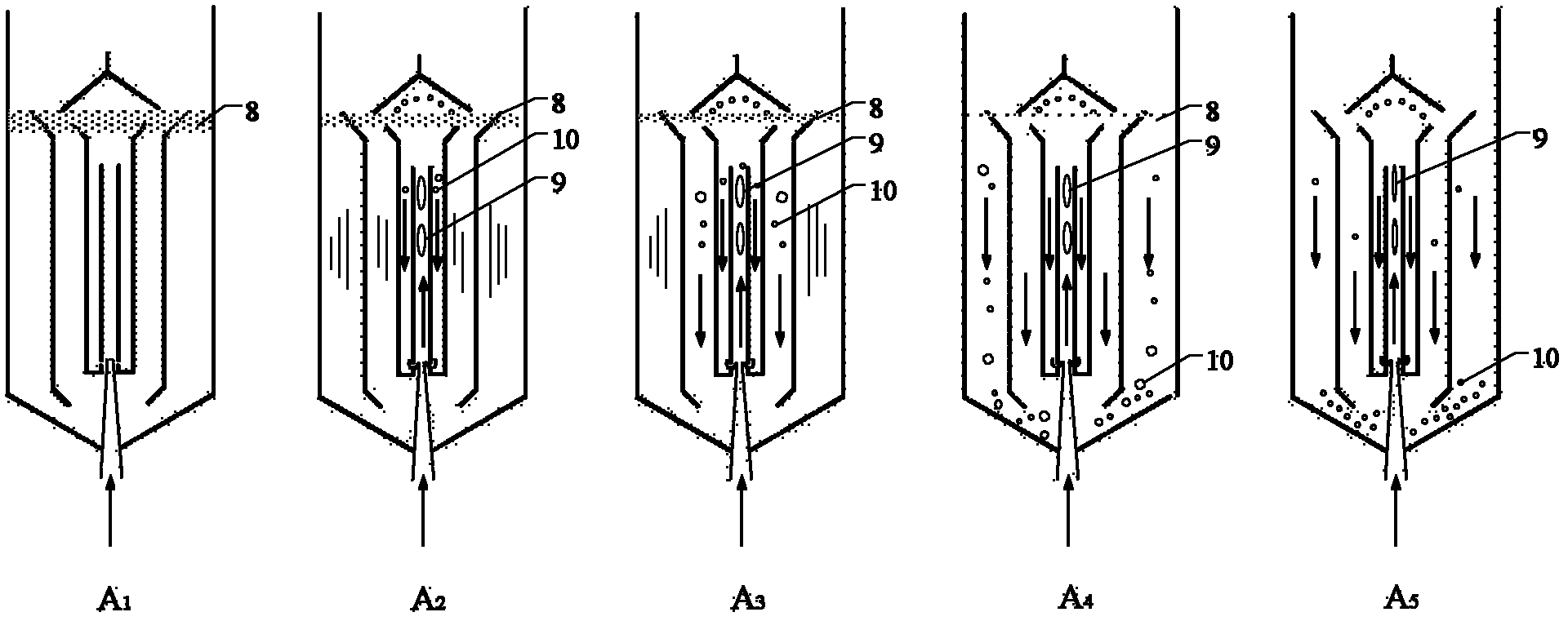

[0037] A kind of air lift type air stirring multi-layer circulation extraction method, such as figure 2 As shown, first add the mixed liquid to be extracted into the extraction device, and then add the light phase 8; after the ventilation starts, bubbles 9 are generated in the inner center tube 4, and a small cycle of the light phase 8 being sucked down is carried out between the two center tubes, and the light phase 8 is lightly absorbed at the same time. The phase 8 is broken; then the liquid in the inner and outer tubes starts to participate in the circulation one after another, and the light phase 8 is further broken; after a period of time, the light phase droplets 10 are completely mixed with the mixed liquid phase, and a stable multi-layer circulation begins to form.

[0038] The device of the present invention is combined with an air-lift air-stirred reactor disclosed in the prior patent CN 2403494Y to carry out the mixing operation of the light phase in the heavy phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com