An automatic circular arc saw tooth grinding machine

A gear grinding machine and arc technology, which is applied in the field of automatic circular arc saw gear grinding machine, can solve the problems of difficulty in meeting mass production, low intelligence and low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

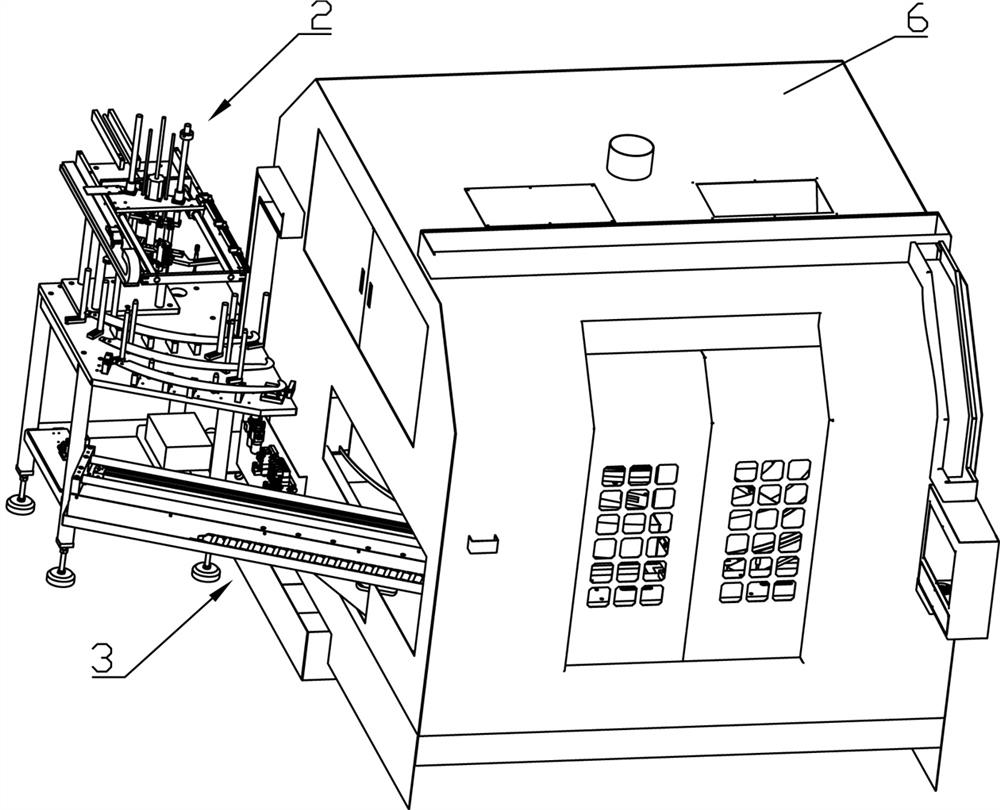

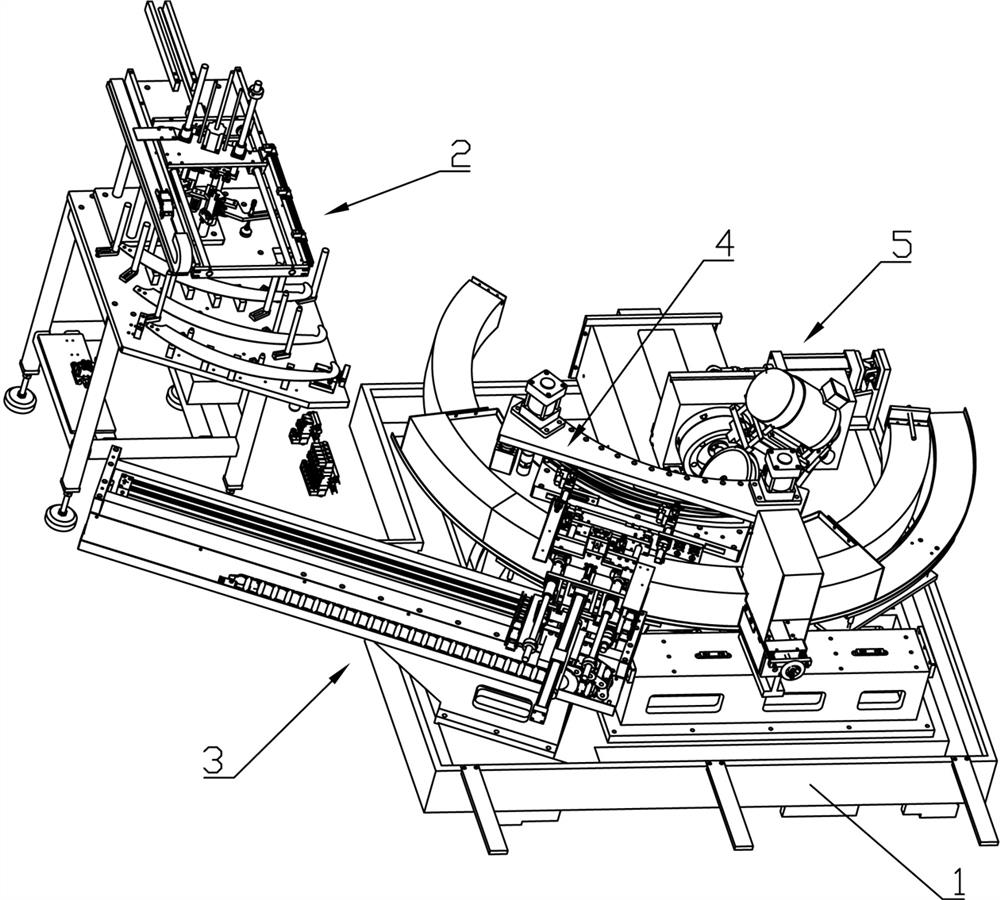

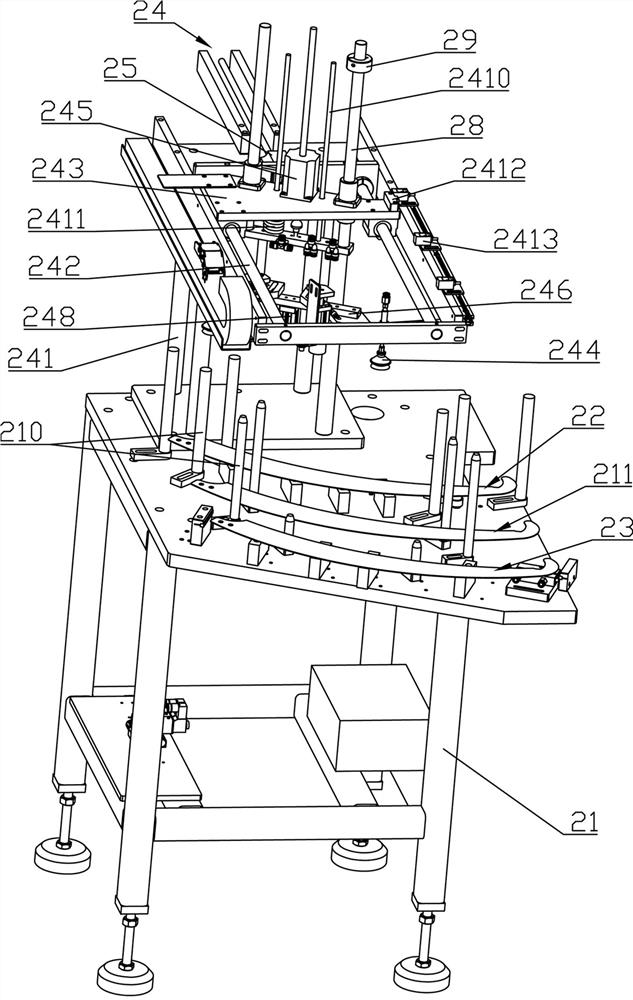

[0028] like Figure 1 to Figure 11As shown, an automatic arc saw gear grinding machine includes a base 1, a material temporary storage mechanism 2, a material shifting mechanism 3, and a gear grinding mechanism 5. The base 1 is provided with an arc track 11 and a mounting seat 12, and the arc track 11 slides and is provided with workbench 13, and workbench 13 is provided with the positioning device 4 of positioning workpiece, and workbench 13 is also provided with first arc rack 14, and mounting base 12 is provided with first driving motor 15, and The output shaft of a drive motor 15 is provided with the first gear 16 meshing with the first arc rack 14; Station 22 and the second station 23, the first support 21 is provided with the sucker devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com