A high-yield polymalic acid Aureobasidium pullulans and its application

A technique of Aureobasidium pullulans and polymalic acid, applied in the direction of microorganism-based methods, fungi, microorganisms, etc., can solve the problems of high raw material cost, difficult quality control, low yield of polymalic acid, etc., and meet the simple nutritional requirements of strains , reduce the consumption of cooling water, the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 : Screening and Identification of Strains

[0034] 1.1 Screening process of strain GXZ-6

[0035] Enrichment culture: Weigh 5g of fresh leaf samples into a 250mL Erlenmeyer flask filled with 50mL of enrichment medium, culture at 30°C for 2 days at a shaker speed of 180rpm, to obtain a bacterial suspension. The concentration components of the enrichment medium are as follows: mannitol 100g / L, ammonium nitrate 1g / L, citric acid 2g / L, KH 2 PO 4 0.5g / L, MgSO 4 ·7H 2 O 0.2g / L, Tween-80 0.2g / L, distilled water to 1L, natural pH.

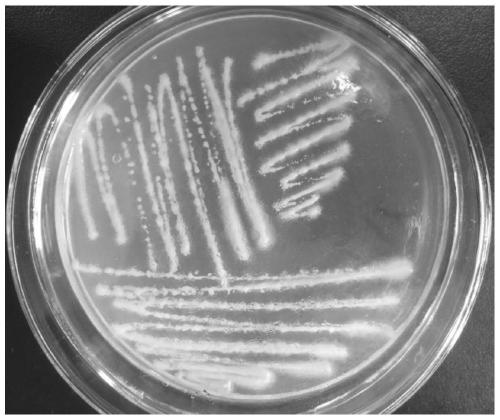

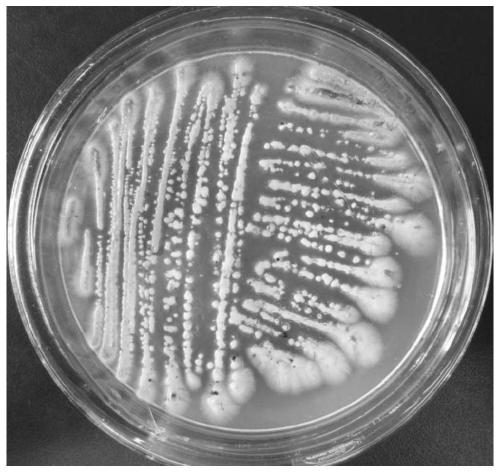

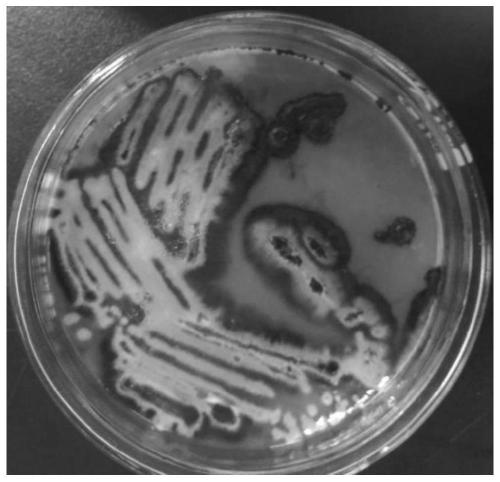

[0036] Bacterial suspension dilution and colony picking: The bacterial suspension obtained above was diluted into bacterial suspensions of different concentrations using the 10-fold dilution method, and 10 4 , 10 5 , 10 6 100 μL of the bacterial suspension was spread on the PDA plate medium, incubated at 30°C for 2 days, and yeast-like viscous colonies were picked. The concentration and components of the PDA medium are as follow...

Embodiment 2

[0051] Example 2 : Method for producing polymalic acid by fermentation of Aureobasidium pullulans GXZ-6 bacterial strain

[0052] (1) Strain activation: Aureobasidium pullulans GXZ-6 preserved in glycerin was streaked on a PDA slant medium, and cultured at a constant temperature of 28° C. for 3 days;

[0053] (2) Seed culture: Take one ring of activated slant strains, inoculate in a 500mL Erlenmeyer flask with 50mL liquid seed medium, shaker speed 160rpm, and cultivate at 25°C for 48h to obtain seed liquid; the concentration of liquid seed medium The components are as follows: glucose 80g / L, sodium nitrate 2g / L, KCl 0.4g / L, KH 2 PO 4 0.05g / L, MgSO 4 ·7H 2 O 0.1g / L, ZnSO 4 ·7H 2 O 0.05g / L, CaCO 3 15g / L;

[0054] (3) Fermentation culture: the seed liquid is inserted in the 250mL Erlenmeyer flask that 30mL liquid fermentation medium is housed according to 8% inoculation amount, shaker rotating speed 160rpm, 25 ℃ cultivates 9 days; The concentration component of liquid f...

Embodiment 3

[0058] Example 3 : Method for producing polymalic acid by fermentation of Aureobasidium pullulans GXZ-6 bacterial strain

[0059] Aureobasidium pullulans (Aureobasidium pullulans) GXZ-6 fermentation method for producing polymalic acid, the specific steps are:

[0060] (1) Strain activation: Aureobasidium pullulans GXZ-6 preserved in glycerol was streaked on the PDA slant medium, and cultured at 30° C. for 2 days;

[0061] (2) Seed culture: Take one ring of activated slant strains, inoculate in a 500mL Erlenmeyer flask with 100mL liquid seed medium, shaker speed 220rpm, cultivate at 30°C for 36h to obtain seed liquid; the concentration of liquid seed medium The components are as follows: glucose 100g / L, sodium nitrate 4g / L, KCl 0.6g / L, KH 2 PO 4 0.2g / L, MgSO 4 ·7H 2 O 0.3g / L, ZnSO 4 ·7H 2 O 0.2g / L, CaCO 3 30g / L;

[0062] (3) Fermentation culture: the seed liquid is inserted in the 250mL Erlenmeyer flask that 40mL liquid fermentation medium is housed according to 10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com