Method for preparing magnesium-based composite material by lost foam casting

A technology of lost foam casting and composite materials, applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of low product quality, reduce the time of adding particles, refine grains, improve hardness and The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

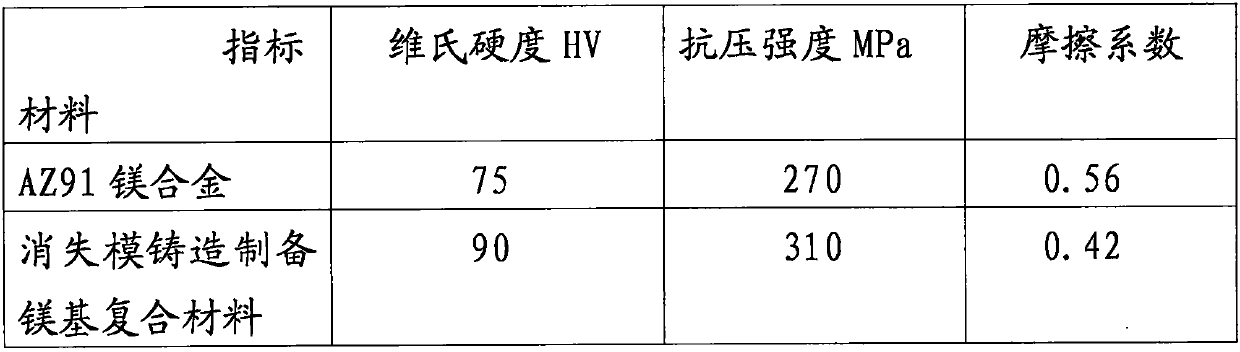

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in detail below. A method for preparing magnesium-based composite materials by lost foam casting, the method steps are:

[0019] ①. Preparation of pre-dispersed mixture of high-entropy alloy particles in magnesium alloy chips: put high-entropy alloy particles with a weight ratio of 1:1-2 and magnesium alloy chips with a size of 0.1-2 mm in a beaker of an electromagnetic stirrer, and place them under normal temperature conditions After electromagnetic stirring at 50-500r / min for 1-5h, then dry at 50-150°C for 1-5h to prepare a pre-dispersed mixture;

[0020] 2. Melt preparation: the pre-dispersed mixture prepared in step 1. is divided into two parts according to the weight ratio of 50%, wherein, 50% of the pre-dispersed mixture is put into the resistance furnace together with the magnesium alloy ingot, and the Furnace temperature 680-750 ℃ and protective gas protection for smelting. After the magnesium alloy ingot is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com