A fermentation culture method capable of increasing the yield of subtilis lipopeptide sodium

A technology of sodium subtilisin lipopeptide and fermentation culture is applied in the field of fermentation and culture that can increase the yield of sodium subtilisin lipopeptide, and achieves the effects of promoting the synthesis of lipopeptide subtilisin, increasing the yield, and satisfying industrialized large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A fermentation culture method capable of increasing the output of subtilis lipopeptide sodium, the following steps are adopted:

[0029] (1) Seed bacteria culture: take Bacillus subtilis BS-37 as the starting strain, transfer the preserved strains to LB plates, and place them in a 37°C incubator to activate for 24 hours; The loops were inoculated in the seed liquid medium, cultured on a shaking table at 28 °C and 210 rpm / min for 24 h, and then used as seed bacteria for future use. The composition of seed liquid medium is: beef extract 4.0 g / L, peptone 12.0 g / L, yeast extract 6.0 g / L, NaCl 3.0 g / L, glucose 8.0 g / L, pH 6.8.

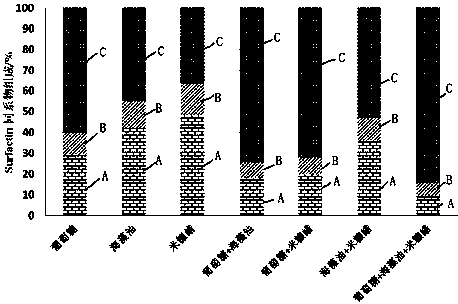

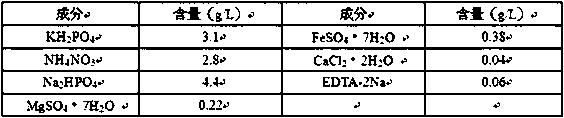

[0030] (2) Fermentation culture: Inoculate the seed bacteria cultivated in step (1) with 24.0 g of glucose, 2.4 g of seaweed oil, 0.8 g of rice bran wax, and 6.0 g of D-glutamic acid at an inoculation volume of 3.0% by volume. g, D-leucine 1.0 g basic inorganic salt medium (MMSM medium) (see Table 4 for the formula), cultured on a shaker at 34°C and...

Embodiment 2

[0035] A fermentation culture method capable of increasing the output of subtilis lipopeptide sodium, the following steps are adopted:

[0036] (1) Seed bacteria culture: take Bacillus subtilis BS-37 as the starting strain, transfer the preserved strains to LB plates, and place them in a 37°C incubator to activate for 24 hours; The loop was inoculated in the seed liquid medium, cultured on a shaker at 28°C and 210 rpm / min for 24 h, and then used as a seed fungus for later use. The composition of seed liquid medium is: beef extract 4.0 g / L, peptone 12.0 g / L, yeast extract 6.0 g / L, NaCl 3.0 g / L, glucose 8.0 g / L, pH 6.6.

[0037] (2) Fermentation culture: Inoculate the seed bacteria cultivated in step (1) according to the inoculum size of 5.5% by volume, and insert them into the fermentation medium supplemented with 36.0 g of glucose, 3.8 g of seaweed oil, 2.4 g of rice bran wax, and 4.0 g of D-glutamic acid. g, D-leucine 0.5 g basal inorganic salt medium (MMSM medium) (see Tabl...

Embodiment 3

[0042] A fermentation culture method capable of increasing the output of subtilis lipopeptide sodium, the following steps are adopted:

[0043] (1) Seed bacteria culture: take Bacillus subtilis BS-37 as the starting strain, transfer the preserved strains to LB plates, and place them in a 37°C incubator to activate for 24 hours; The loop was inoculated in the seed liquid medium, cultured on a shaker at 28°C and 210 rpm / min for 24 h, and then used as a seed fungus for later use. The composition of seed liquid medium is: beef extract 4.0 g / L, peptone 12.0 g / L, yeast extract 6.0 g / L, NaCl 3.0 g / L, glucose 8.0 g / L, pH 7.0.

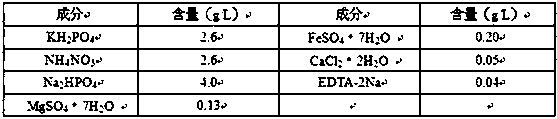

[0044] (2) Fermentation culture: Inoculate the seed bacteria cultivated in step (1) with 50.0 g of glucose, 15.0 g of seaweed oil, 5.0 g of rice bran wax, and 5.0 g of D-glutamic acid at an inoculum size of 8.0% by volume. g, D-leucine 1.0 g basal inorganic salt medium (MMSM medium) (see Table 6 for the formula), cultured on a shaker at 36°C and 280 rpm / min fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com