Vertical multi-stage mixing clarifying extracting device by air stirring and extracting method thereof

A technology of air agitation and extraction equipment, which is applied in the direction of solid solvent extraction, liquid solution solvent extraction, etc., to achieve continuous operation, meet industrial mass production, and avoid emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

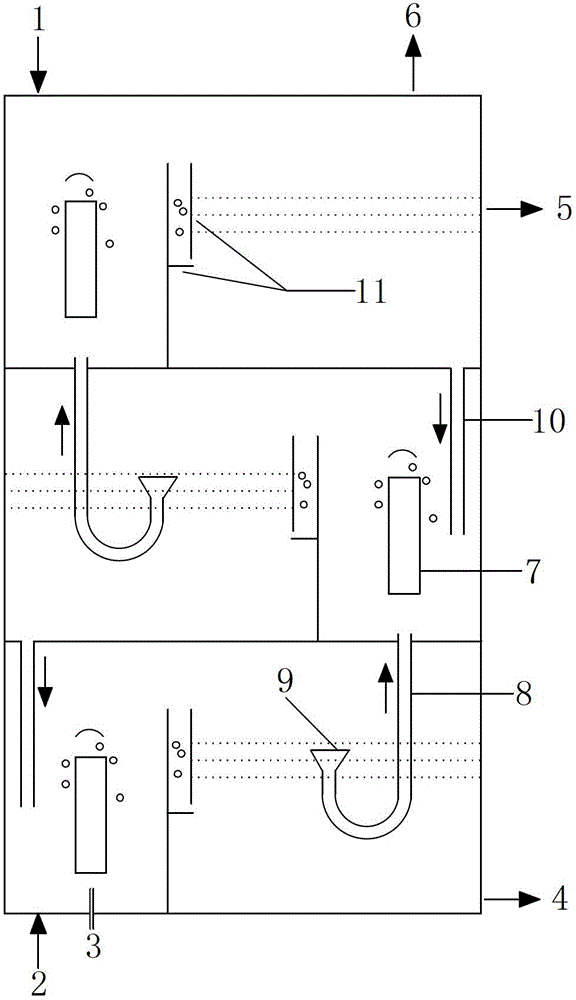

[0046] A kind of air stirring vertical multi-stage mixing clarification extraction device, such as figure 1 As shown, it is composed of 3 stages of extraction tanks stacked in series from bottom to top; each stage of extraction tank is divided into mixing tanks and clarification tanks, and the mixing tanks and clarification tanks at all levels are arranged alternately from left to right. An air agitator 7 is arranged in the mixing tank. A conduit 8 is connected to the bottom of the mixing tank, and the conduit 8 is located in the clarification tank of the previous stage. One end of the conduit 8 is connected to the bottom of the mixing tank, and an inverted cone 9 is welded at the other end. The bottom of the clarification tank is connected with a heavy phase guide pipe 10, and the heavy phase guide pipe 10 is located in the mixing tank of the previous stage.

[0047] An air outlet 6 is provided on the top of the clarification tank at the uppermost end of the device, and an a...

Embodiment 2

[0049] An air-stirred vertical multi-stage mixing and clarifying extraction device, which is composed of 30 stages of extraction tanks stacked in series from bottom to top; each stage of extraction tank is divided into a mixing tank and a clarification tank, and the mixing tank and the clarification tank Sort left and right alternately. An air agitator 7 is arranged in the mixing tank. A conduit 8 is connected to the bottom of the mixing tank, and the conduit 8 is located in the clarification tank of the previous stage. One end of the conduit 8 is connected to the bottom of the mixing tank, and an inverted cone 9 is welded at the other end. The bottom of the clarification tank is connected with a heavy phase guide pipe 10, and the heavy phase guide pipe 10 is located in the mixing tank of the previous stage.

[0050] An air outlet 6 is provided on the top of the clarification tank at the uppermost end of the device, and an air inlet 3 is provided at the bottom of the mixing t...

Embodiment 3

[0052] An air-stirred vertical multi-stage mixing and clarifying extraction device, which is composed of 15 stages of extraction tanks stacked in series from bottom to top; each stage of extraction tank is divided into mixing tank and clarification tank, and the mixing tank and clarification tank Sort left and right alternately. An air agitator 7 is arranged in the mixing tank. A conduit 8 is connected to the bottom of the mixing tank, and the conduit 8 is located in the clarification tank of the previous stage. One end of the conduit 8 is connected to the bottom of the mixing tank, and an inverted cone 9 is welded at the other end. The bottom of the clarification tank is connected with a heavy phase guide pipe 10, and the heavy phase guide pipe 10 is located in the mixing tank of the previous stage.

[0053] An air outlet 6 is provided on the top of the clarification tank at the uppermost end of the device, and an air inlet 3 is provided at the bottom of the mixing tank at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com