Clock-shaped shell plunger tip and processing technology of clock-shaped shell

A bell-shaped shell and punch technology, which is applied in metal processing equipment, manufacturing tools, indenters/punch rods, etc., can solve the problems of increasing production costs and material costs, complex processing technology, and unfavorable productivity, and achieves simple structure, The effect of reducing the process flow and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

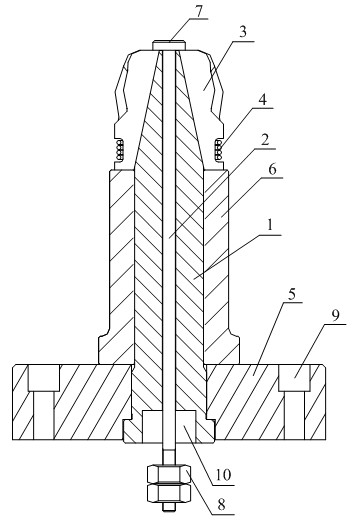

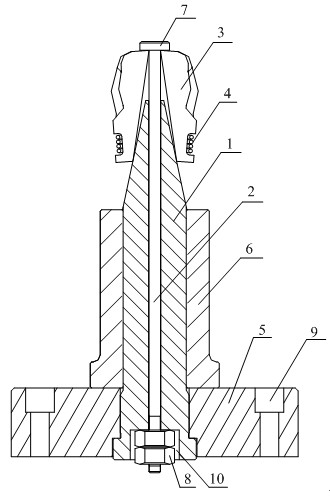

[0035] Such as Figure 1~4 As shown, the present invention is mainly composed of a hexagonal seat 1. The hexagonal seat 1 has a cylindrical structure as a whole. become. In order to facilitate the forming of the bell-shaped shell blank, a forming punch is provided on the hexagonal seat 1 .

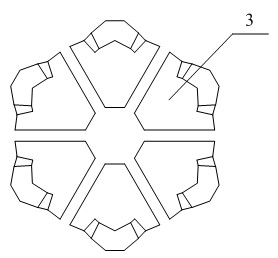

[0036] The forming punch is covered on the top of the hexagonal seat 1, and the forming punch includes more than two punch blocks 3 with the same structure, such as figure 2 , 4 As shown, the punch block 3 is combined to form an integral forming punch, which has a tapered hole matching the frustum-shaped top of the hexagonal seat 1, and the forming punch and the circular shape of the hexagonal seat 1 The top of the platform is fitted on the hexagonal seat 1 after matching, such as figure 1 shown. In order to facilitate the punch block 3 to be connected as an integral forming punch, and the forming punch is placed on the hexagonal seat 1, the punch block 3 is also covered with an O th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap