Tool for punching back film of photovoltaic component

A photovoltaic module and back film technology, applied in the field of machinery, can solve the problems of increasing labor intensity of workers, long positioning time, slow opening speed, etc., and achieve the effect of reducing labor intensity of employees and operation, reasonable structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiment:

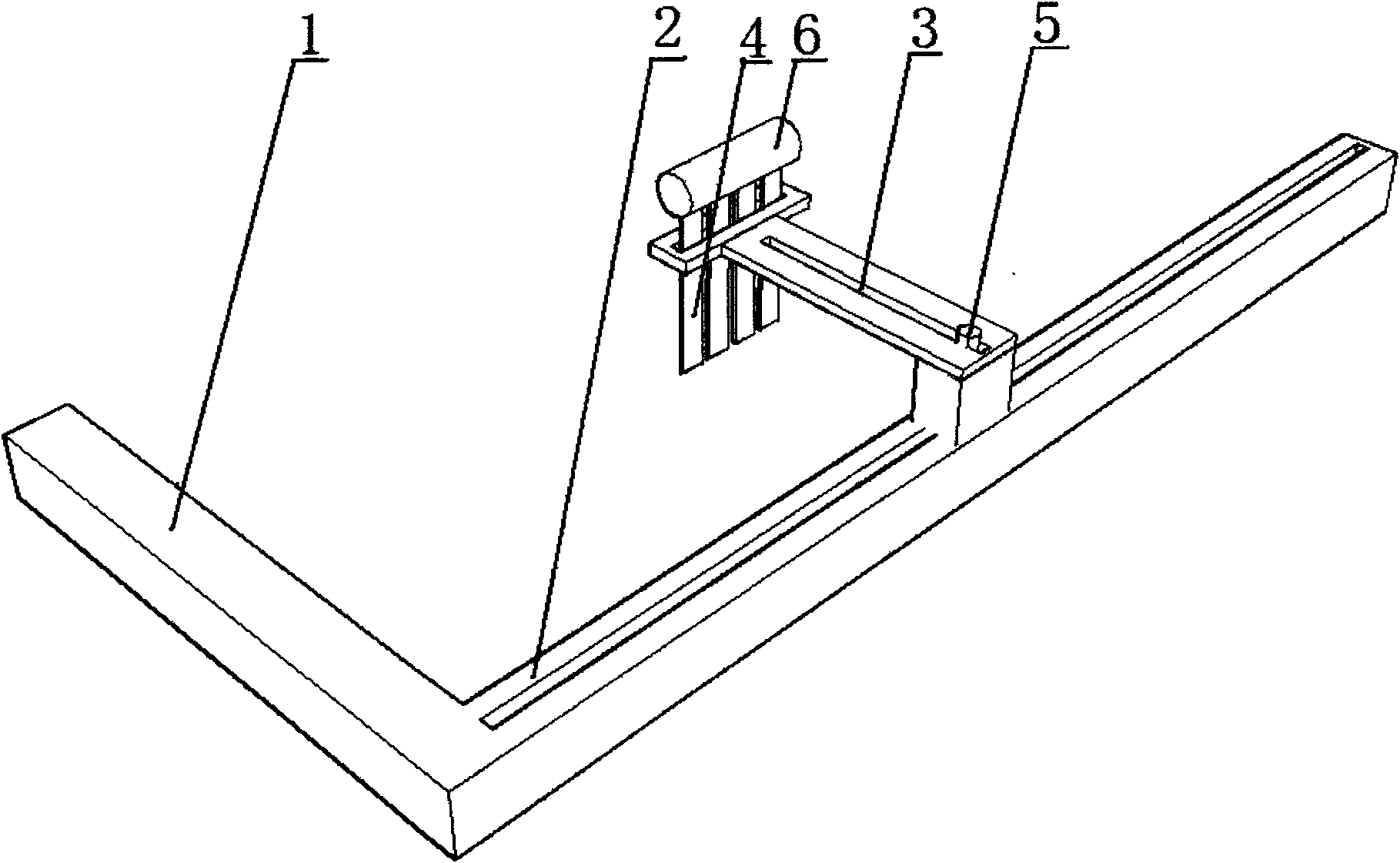

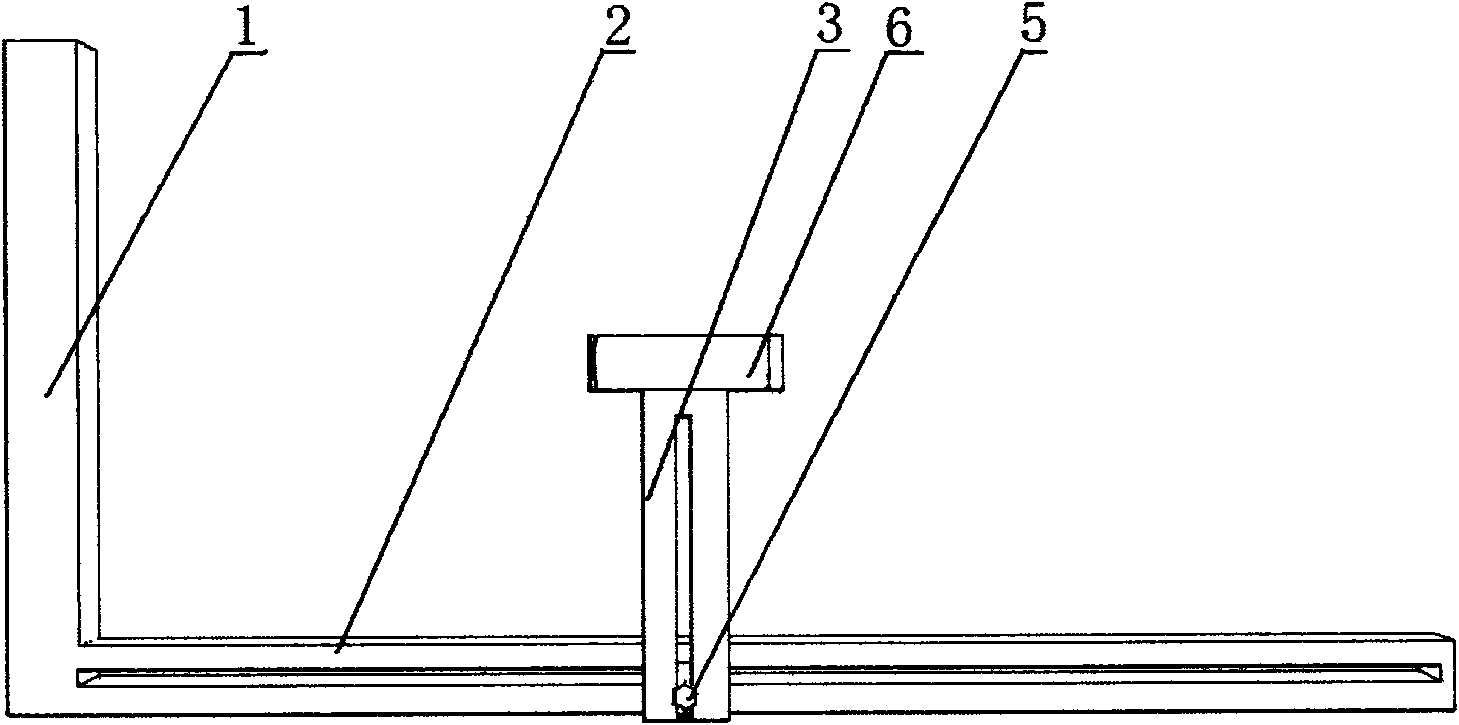

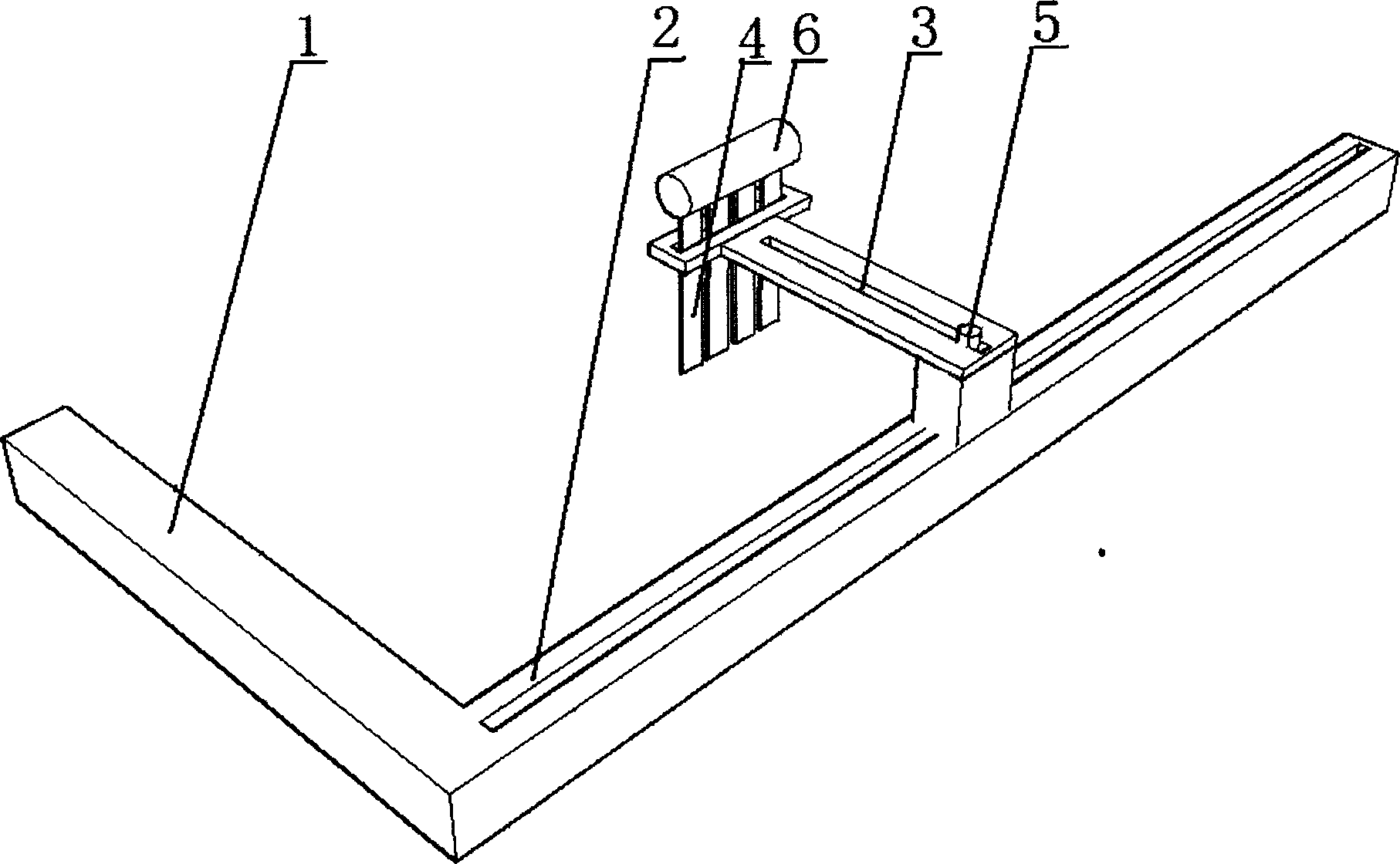

[0011] As shown in the drawings, a photovoltaic module back film opening tool includes a short template 1 and a long template 2 perpendicular to each other, a tool holder 3, and a blade 4. The tool holder 3 is connected to the long template 2 through a module adjustment screw 5 , the blade 4 vertically passes through the front end of the tool holder 3, the upper end of the blade 4 is connected with a pressurized handle 6, the long template 2 and the cutter holder 3 are respectively provided with scales, and the zero point of the scale of the long template 2 is located inside the two templates At the intersection, the zero starting point of the tool holder 2 scale is located on the parallel line of the blades 3, and each blade of the blades 4 is independently and flexibly connected with the pressurized handle 6. When using, select the appropriate blade 4 to form the up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com