Method for manufacturing inner core used for moulding of carbon fiber composite multi-way tube

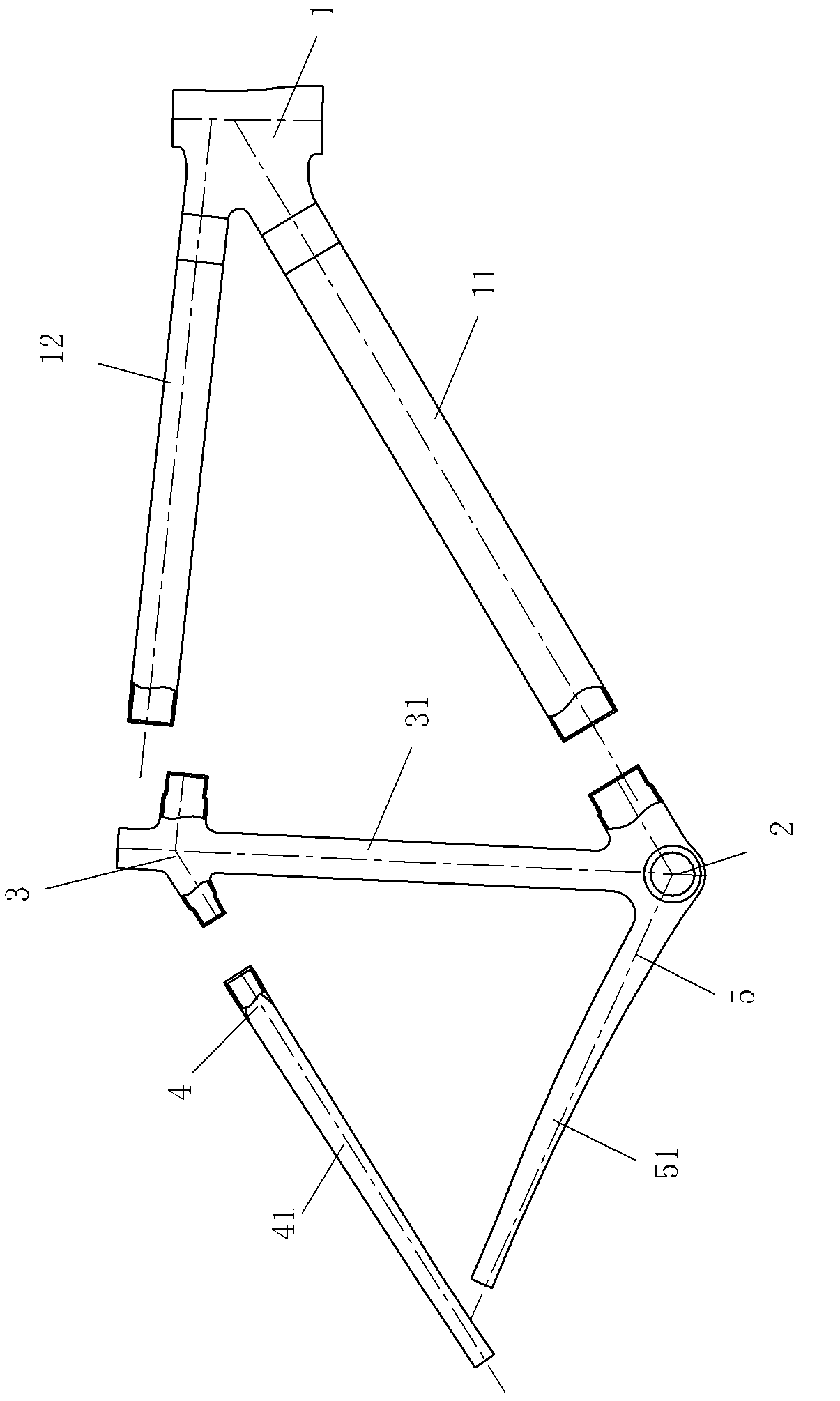

A manufacturing method and a technology for a multi-pass tube, which are applied in the manufacture of bicycle parts, can solve problems such as cracking, and achieve the effects of ensuring normal molding, improving economic benefits, and preventing excessive expansion and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

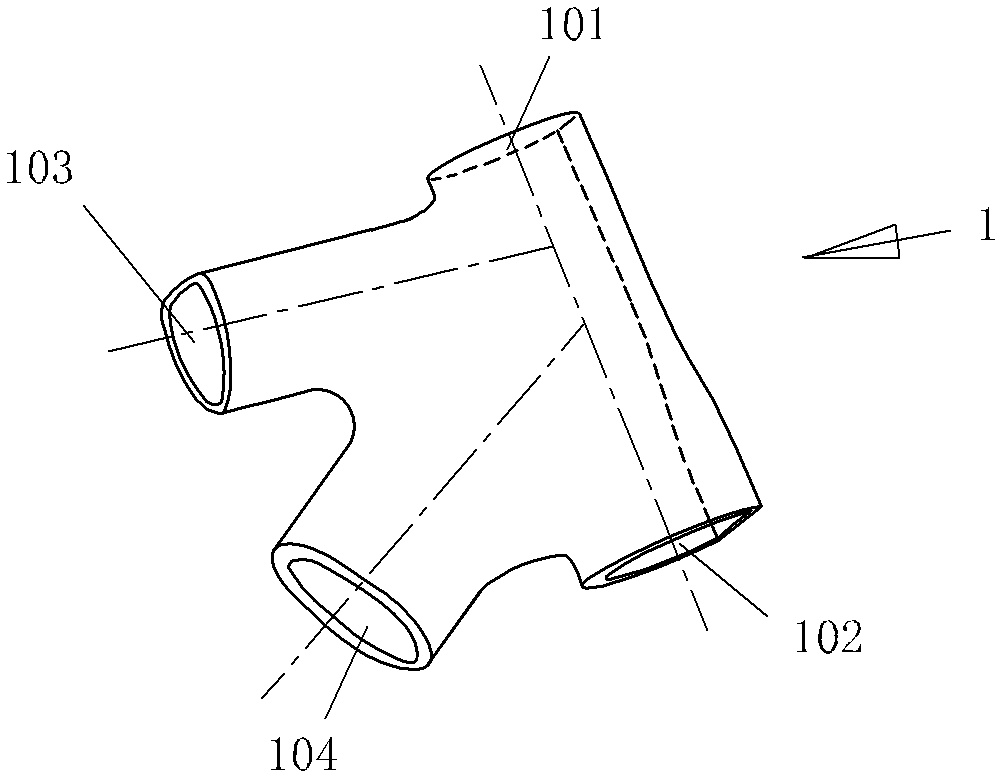

[0031] Adopt the present invention to make and figure 2 The inner core 10 formed by the head pipe corresponding to the carbon fiber composite material head pipe 1 . The inner core 10 that adopts the present invention to manufacture car head tube molding has the following steps:

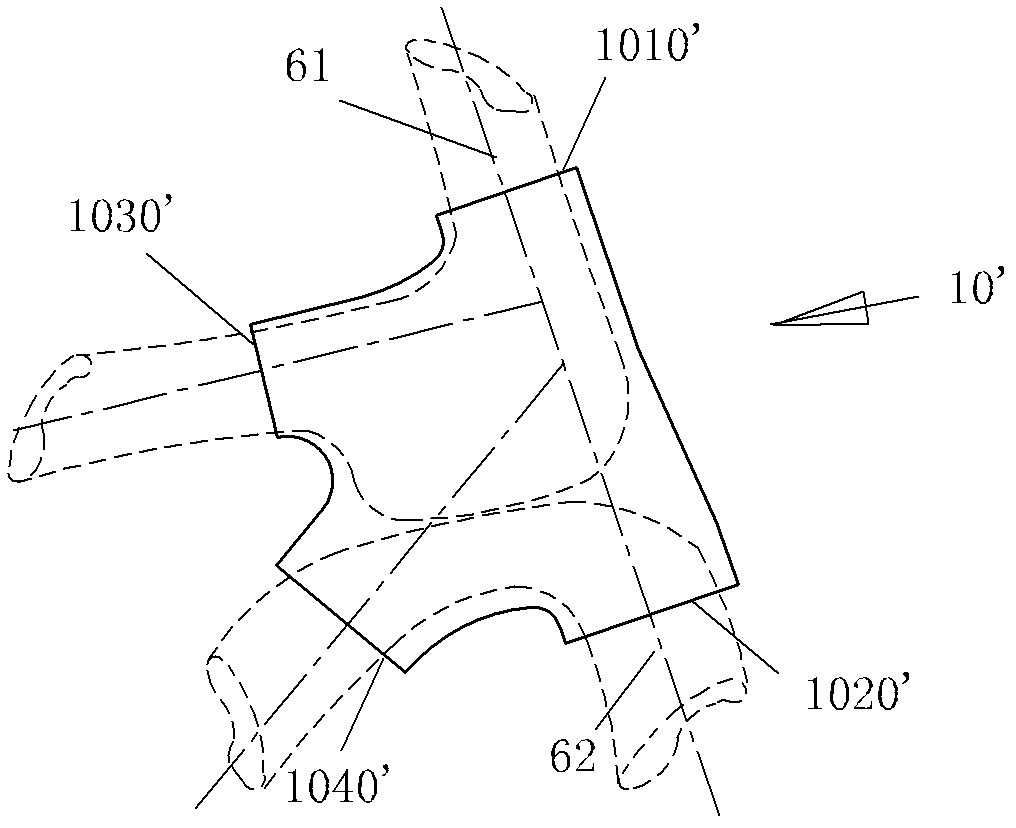

[0032] Step 1, according to the shape of the inner wall of the head pipe 1, split it horizontally along the middle part, and design a thin-walled first core pipe part 110 and a thin-walled second core pipe part 120. The first core tube 110 only has an upper port 1010 corresponding to the upper port 101 of the head pipe 1 and a rear upper port 1030 corresponding to the rear upper port 103 of the head pipe 1 , and is only for inserting one air duct 61 . The second core pipe 120 only has a lower port 1020 corresponding to the lower port 102 of the headpipe 1 and a rear lower port 1040 corresponding to the rear lower port 104 of the headpipe 1 and is only used for inserting another air duct 62 . The su...

Embodiment 2

[0037] Present embodiment adopts the present invention to make and figure 2 The inner core 100 formed by the carbon fiber composite head pipe 1 corresponding to the head pipe has the following steps:

[0038] Step 1, according to the shape of the inner wall of the head pipe 1, split it horizontally along the middle part, and design a thin-walled first core pipe part 1100 and a thin-walled second core pipe part 1200. The first core pipe 1100 only has an upper port 10100 corresponding to the upper port 101 of the head pipe 1 and a rear upper port 10300 corresponding to the rear upper port 103 of the head pipe 1 , and is only for inserting one air duct 61 . The second core pipe 1200 only has a lower port 10200 corresponding to the lower port 102 of the headpipe 1 and a rear lower port 10400 corresponding to the rear lower port 104 of the headpipe 1 and is only used for inserting another air duct 62 . The surface adjacent to the second core pipe part 1200 on the first core pipe ...

Embodiment 3

[0043] Present embodiment adopts the present invention to make and figure 2 The inner core 1000 formed by the carbon fiber composite head pipe 1 corresponding to the head pipe has the following steps:

[0044] Step 1, according to the shape of the inner wall of the head pipe 1, it is split longitudinally, and designed into a thin-walled straight core pipe 11000 and a thin-walled U-shaped core pipe 12000. The straight core pipe 11000 only has an upper port 101000 corresponding to the upper port 101 of the headpipe 1 and a lower port 102000 corresponding to the lower port 102 of the headpipe 1 , and is only used for inserting one air duct 61 . The U-shaped core pipe piece 12000 has only the rear upper port 103000 corresponding to the upper port 101 of the head pipe 1 and the rear lower port 104000 corresponding to the rear lower port 104 of the head pipe 1 and is only for inserting another air duct 62 . The surface adjacent to the U-shaped core pipe 12000 on the straight core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com