Full driving composite adsorption climbing robot

A wall-climbing robot and composite adsorption technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of poor steering flexibility, poor comprehensive performance, poor movement flexibility, etc., to achieve strong load capacity, good movement flexibility, good Effect of Surface Adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

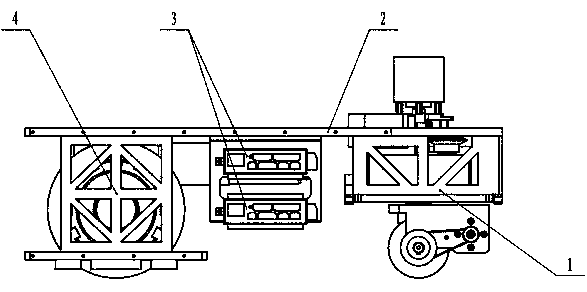

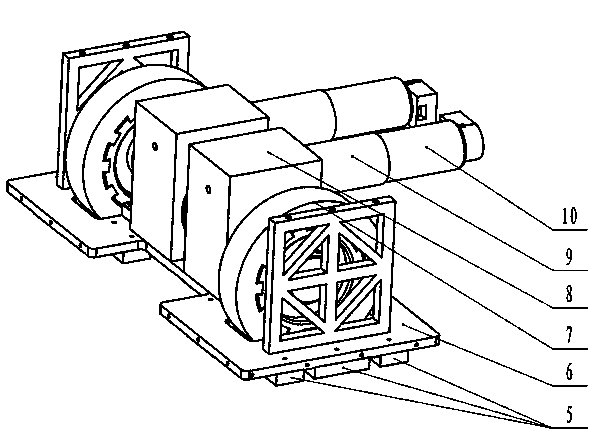

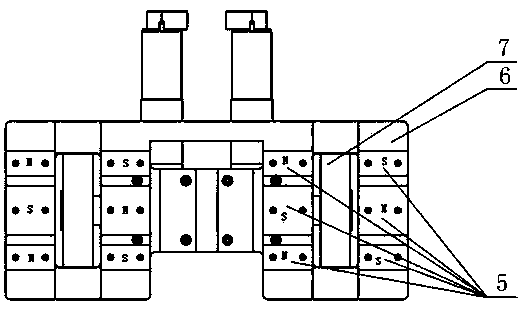

[0035] A new type of full-drive compound adsorption wall-climbing robot includes a crawling mechanism, which includes a front wheel module using a drive-steering integrated magnetic wheel, a rear wheel module using a permanent magnet gap adsorption device, and a frame connecting the front and rear wheels And the motor drive controller installed on the frame; the crawling mechanism is a three-wheel structure, and the three wheels are all driving wheels. The controlled steering of the front wheels is adopted, and the differential speed of the two rear wheels and the controlled steering of the front wheels are used to realize the steering Turning on the magnetic wall. The rear wheel module includes a chassis, a permanent magnet mounted on the rear wheel chassis around the wheel, two rear wheels passing through the chassis, a reducer driving the wheel, a DC motor driving the reducer, and the two rear wheels of the rear wheel module are arranged symmetrically. The front wheel modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com