Driving wheel mechanism of electric scooter

An electric scooter and driving wheel technology, which is applied in the directions of rider driving, vehicle parts, transportation and packaging, can solve the problems of inability to achieve long-term transportation, difficult maintenance, and unfavorable steering, and achieve the effect of center of gravity offset Obvious, good space utilization, and the effect of improving the load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

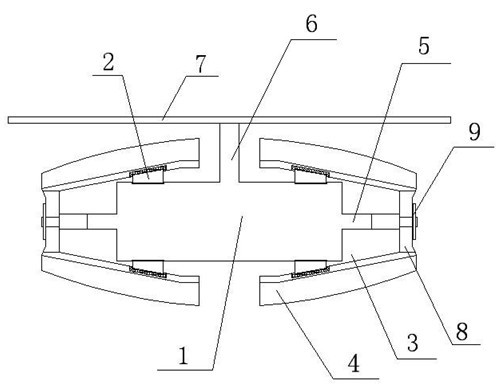

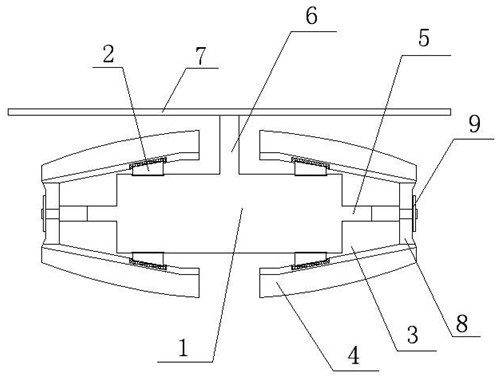

[0015] Such as figure 1 As shown in , the driving wheel mechanism of an electric scooter in the present invention includes a driving wheel and a bracket 6, the driving wheel is composed of a brushless motor 1, a wheel core 3 and a tire 4, and the brushless motor 1 has two-way output shafts, and the two ends are symmetrically socketed Cone-shaped wheel core 3, the outer periphery of wheel core 3 is covered with tire 4, and the tire 4 is correspondingly set in a conical shape. The core 3 is rotated with the motor casing, the upper end of the bracket 6 is connected with the plate body 7 , and the lower end of the bracket 6 is connected with the motor casing of the brushless motor 1 . The operation of the driving wheel mechanism is as follows: the brushless motor 1 starts to operate when it is powered on, the brushless motor 1 is an inner rotor motor, the motor shaft 5 rotates, drives the wheel core 3 to rotate, and the driving wheel runs. The inner rotor motor uses the core in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com