Method and device for judging deviation of conveying belt

A conveyor belt and deviation technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as unattended supervision, functions that cannot be discovered in time, and achieve the effect of avoiding human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

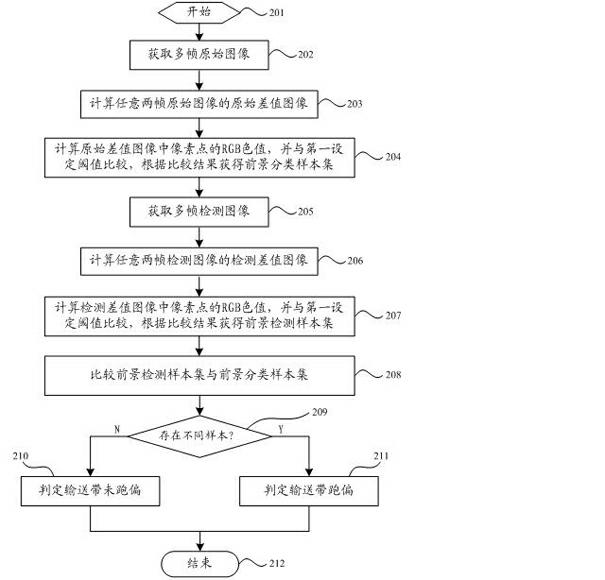

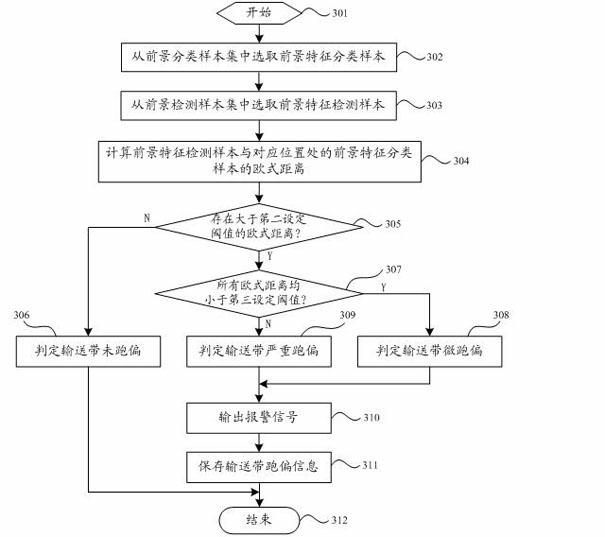

[0040] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

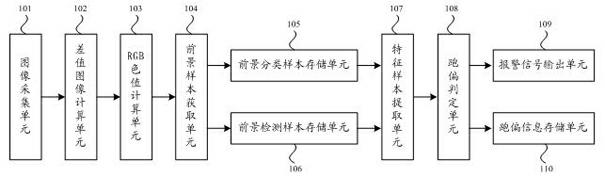

[0041] Please refer to figure 1 ,Should figure 1 Shown is a structural block diagram of an embodiment of the conveyor belt deviation judging device of the present invention, and the direction of the arrow in the figure indicates the connection relationship of each unit and the sequence of work.

[0042] like figure 1 As shown, the conveyor belt deviation judging device of this embodiment specifically includes:

[0043] The image acquisition unit 101 is used to collect images of the environment where the conveyor belt is located, for example, using a camera installed in the environment where the conveyor belt is located to capture images including the conveyor belt, and then collect the image of the camera as the original captured image, i.e. reference comparison The image and the real-time acquisition and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com