Knitting yarn conveyer

A yarn feeding machine and knitting technology, which is applied in knitting, weft knitting, warp knitting, etc., and can solve the problems of affecting the quality of knitting machine fabrics, unstable yarn feeding, and poor positioning of the conveying yarn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is a further detailed description of the technical solution of the present invention in conjunction with the above-mentioned drawings.

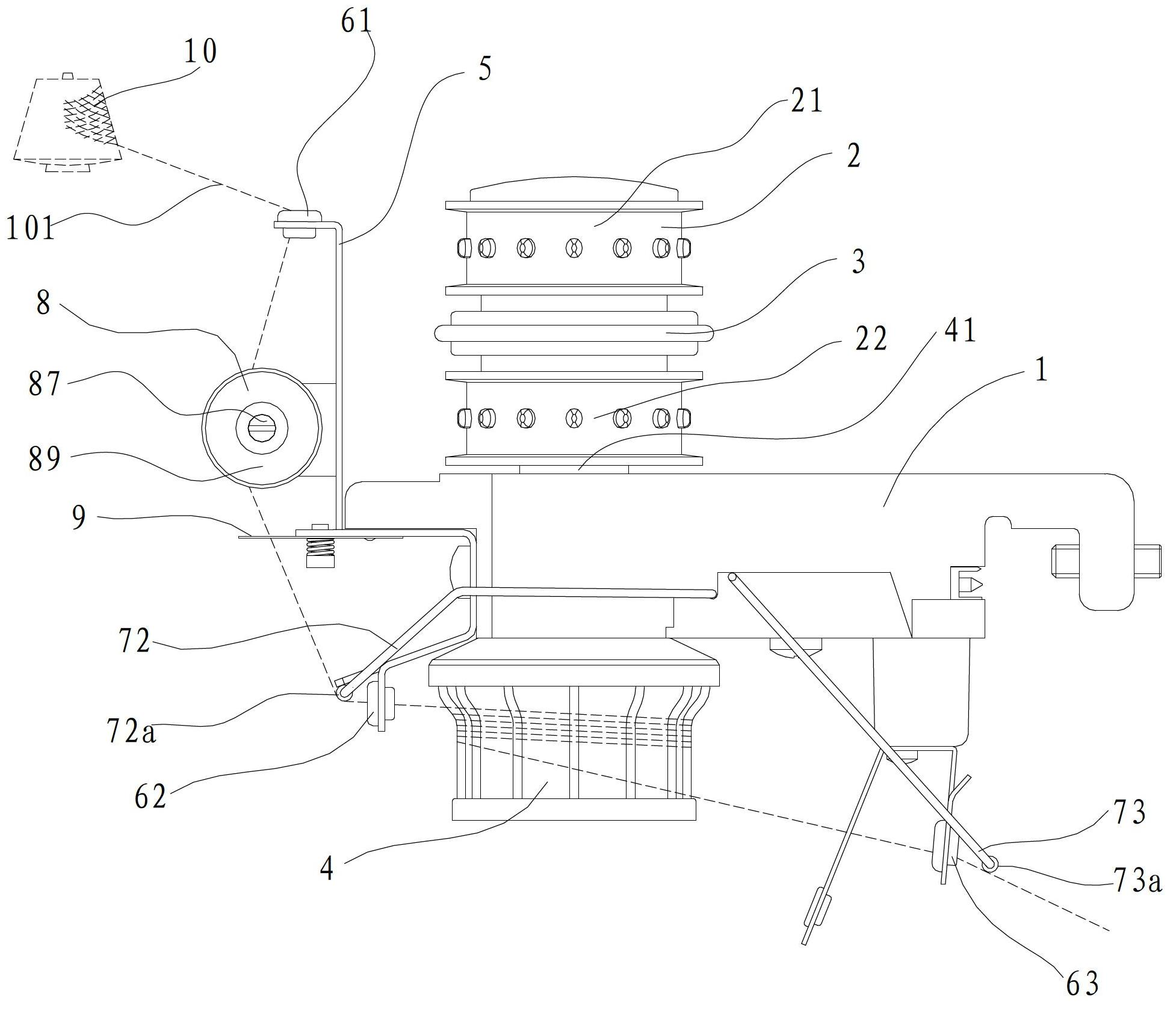

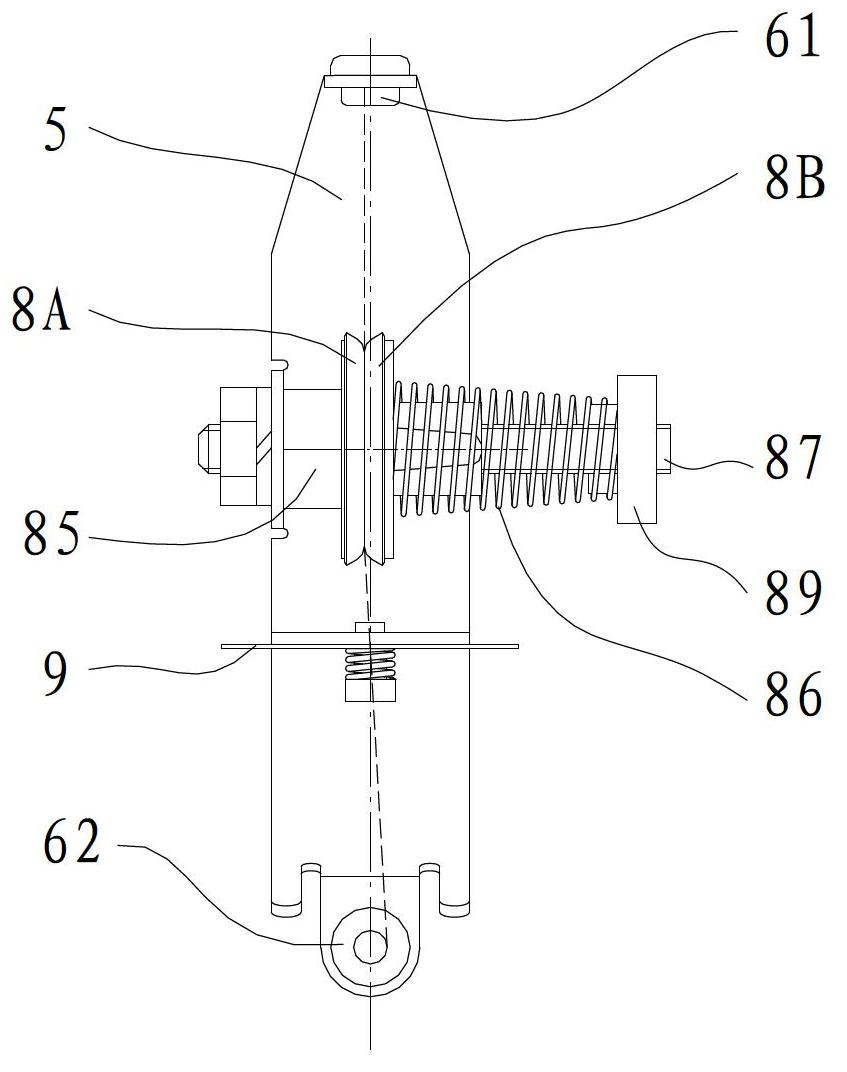

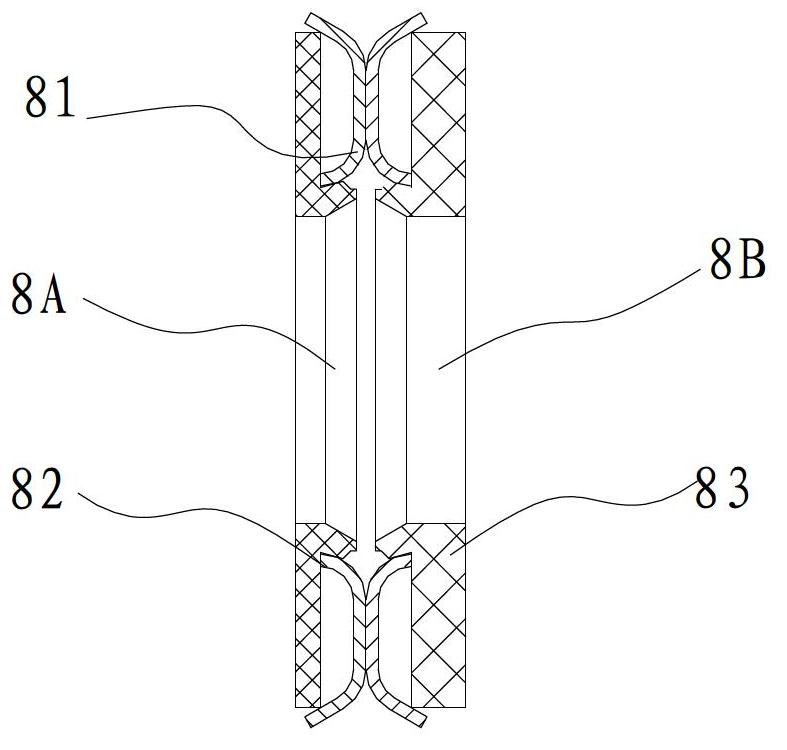

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown knitting yarn feeding machine includes a frame 1, a guiding ceramic ring 61, a lead frame 5, a yarn clamping device 8, a transmission mechanism, a yarn knot filtering device, a front positioning assembly and a rear positioning assembly.

[0016] The yarn tube 10 that feeds yarn also must be adorned in frame 1 outside during knitting yarn feeder operation. The above lead frame 5, yarn knot filtering device, front positioning assembly, transmission mechanism and rear positioning assembly are installed on the frame 1 in sequence, the guide ceramic ring 61 is fixed on the top of the lead frame 5, and the yarn clamping device is located between the guide ceramic ring 61 and the yarn Between the filter devices and through the lead frame 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com