Hydraulic system of excavating machine

A hydraulic system and excavator technology, applied in the field of small excavator hydraulic system and excavator, can solve the problems of energy loss, inability to increase the excavation efficiency of the excavator, etc., and achieve the effects of avoiding waste, saving excavation time, and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

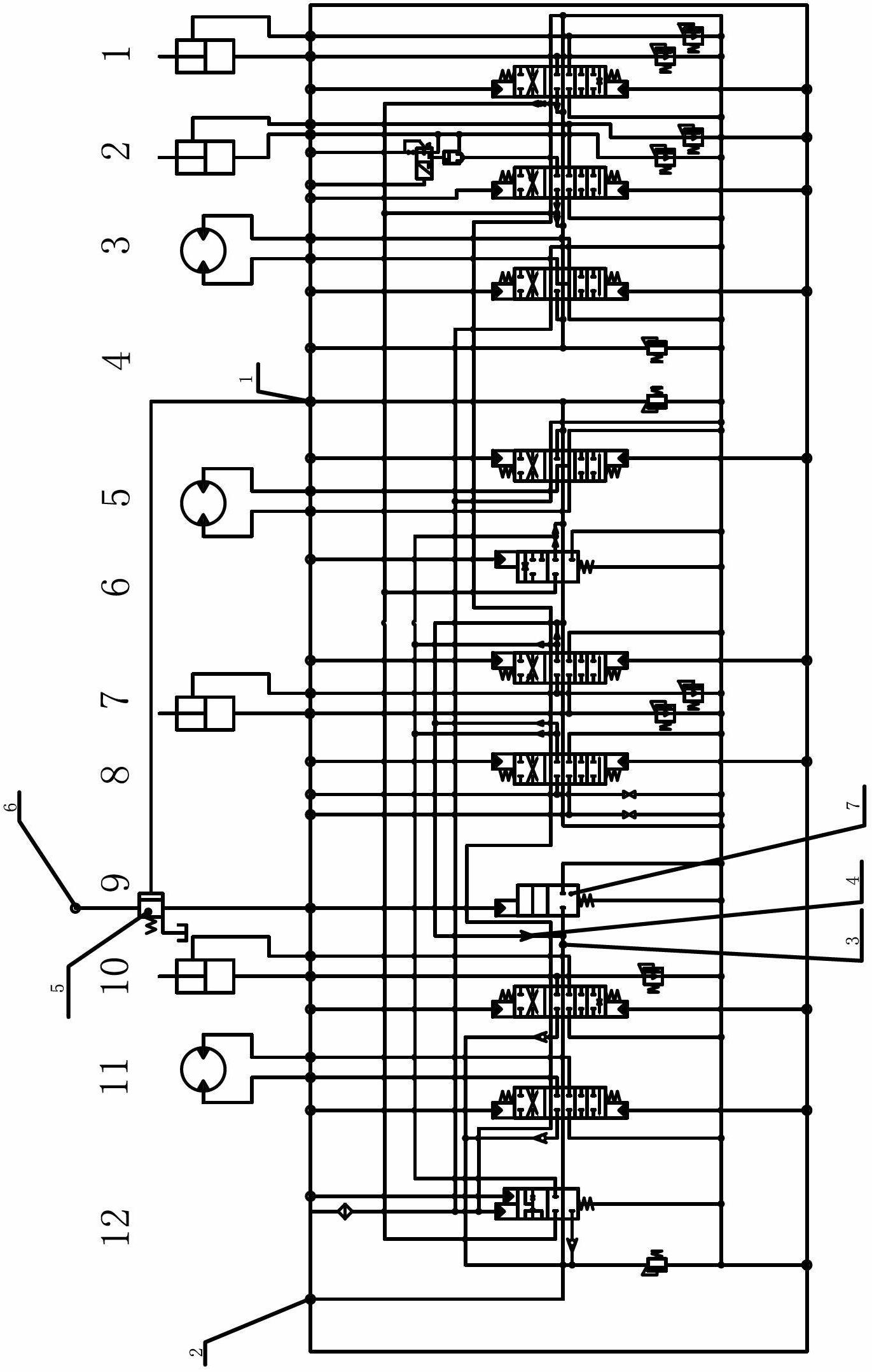

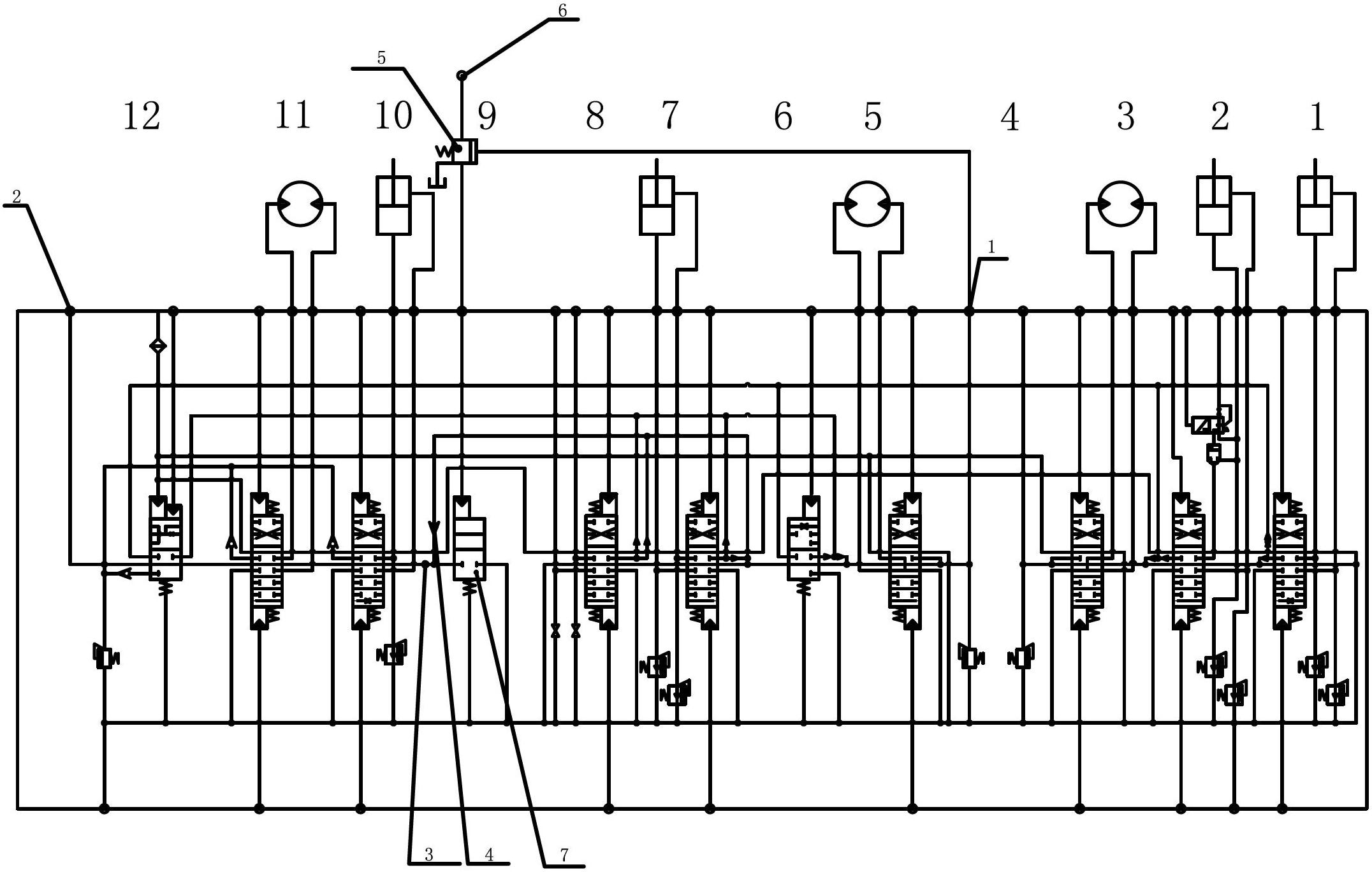

[0015] Such as figure 1 As shown, an excavator hydraulic system includes a main oil circuit and an auxiliary oil circuit 3, the main oil circuit and the auxiliary oil circuit 3 are connected with the excavator stick and the auxiliary oil circuit, the main oil circuit has a main oil pump 1, and the auxiliary oil circuit 3 There is an auxiliary oil pump 2 on the road 3, and a pressure cut-off connection is connected in parallel on the auxiliary oil circuit 3. The pressure cut-off connection can make the main oil circuit and the auxiliary oil circuit 3 merge or unload the auxiliary oil circuit 3 according to the pressure of the main oil pump 1.

[0016] There are two oil circuits connected in parallel on the auxiliary oil circuit 3 , one of which is connected with the stick and the auxiliary circuit through the one-way valve 4 , and the other oil circuit is connected with the pressure cut-off circuit. The pressure cut-off connection includes a sequence valve 5, a pilot pump 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com