Novel high-strength constant-resistance large deformation anchor rod and using method thereof

A technology of constant resistance, large deformation, and anchor rod, which is applied in the installation of anchor rod, earthwork drilling, sheet pile wall, etc., can solve the problems of unstable performance, cracking of the pipe body, insufficient resistance, etc., and achieves simple structure and stable performance. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

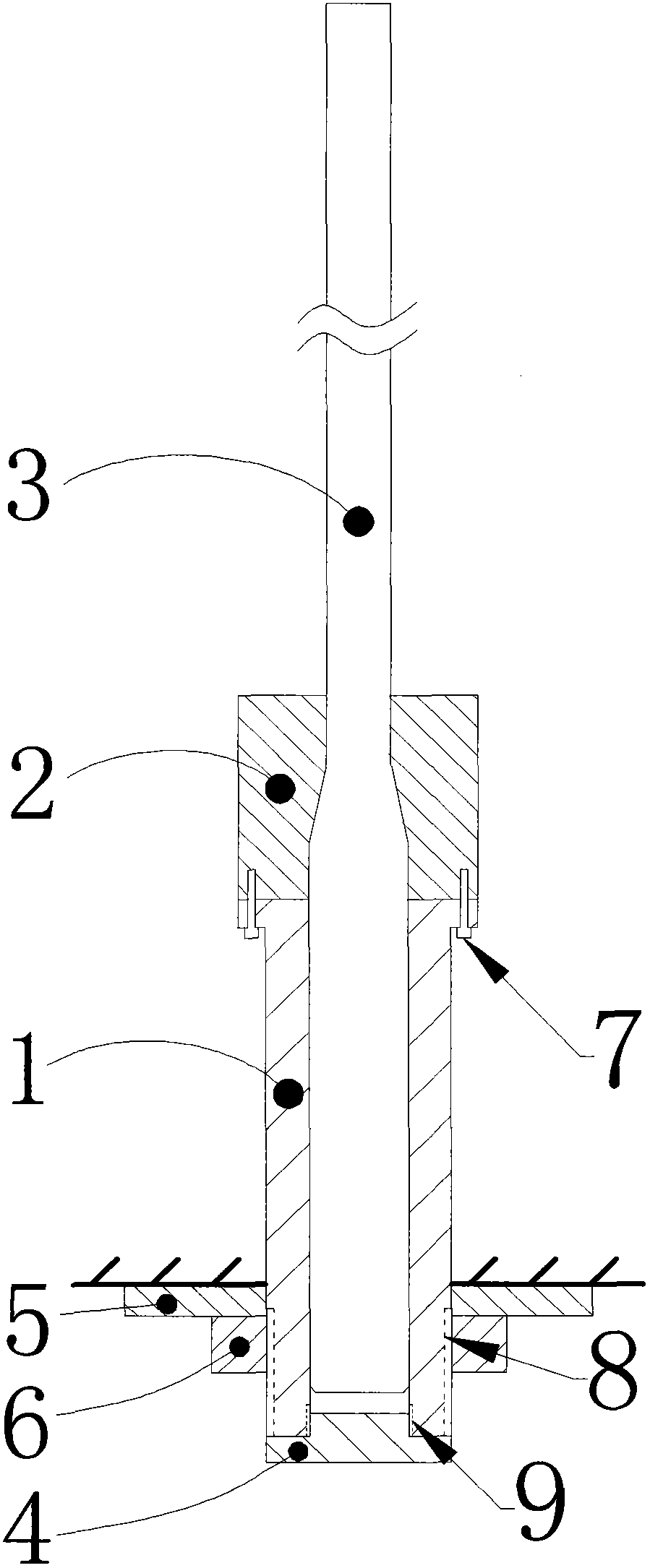

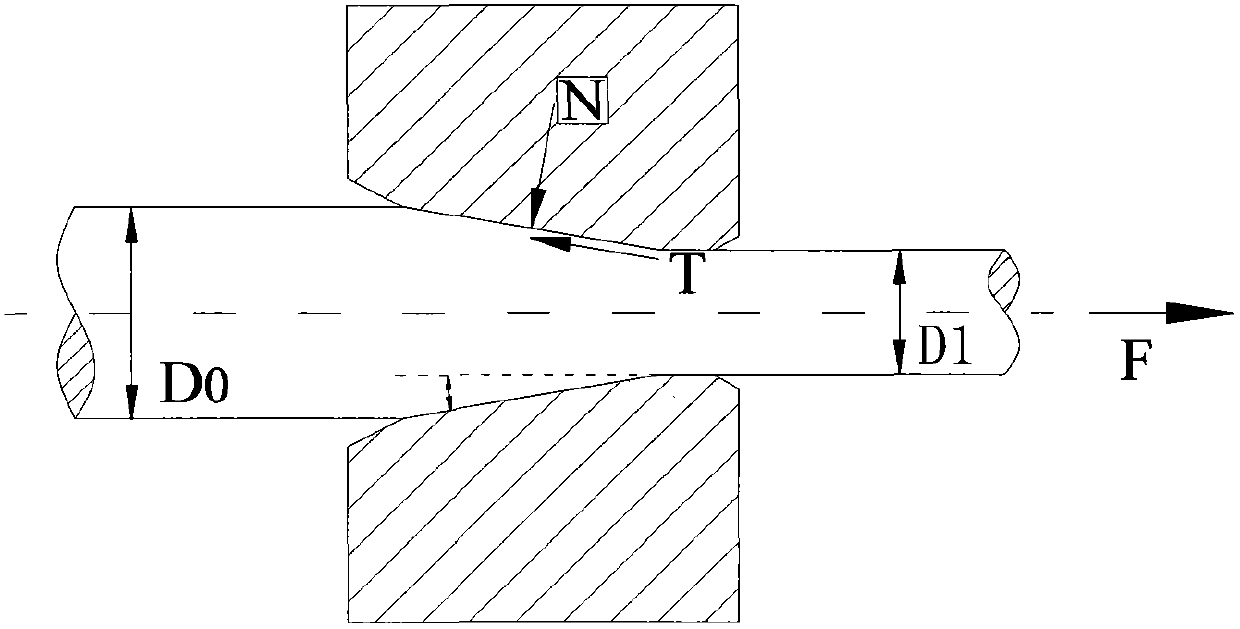

[0041] combine figure 1 , a new type of high-strength, constant-resistance, and large-deformation bolt, which includes a bolt body, a nut 6 and a tray 5, wherein the bolt body includes: a cold-drawn rod body 3, a sleeve 1 and a wire drawing die 2; a cold-drawn rod body 3 The diameter of the section at the rear end is larger than the diameter of the front rod body, that is, one end is a thick section, the other end is a thin section, and the gap between the thick section and the thin section is a tapered section; ; The wire drawing die 2 is a tapered die, the taper of the wire drawing die 2 matches the taper of the cold drawn rod 3 tapered section, and the rear end of the casing 1 is provided with an external thread 8 for installing a nut.

[0042] The above casing 1 is a cylindrical steel pipe, its diameter and wall thickness should meet the anchoring force requirements, and its length should meet the deformation of the designed anchor rod;

[0043] The material of the above-...

Embodiment 2

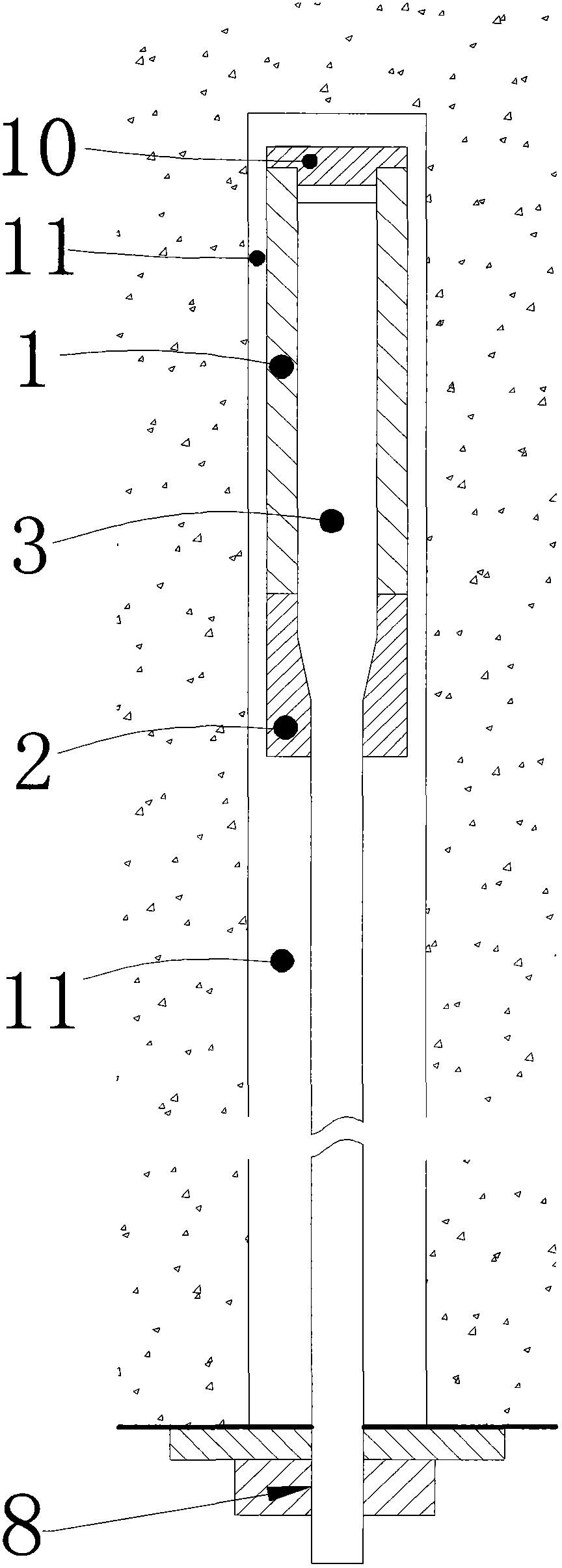

[0053] combine image 3 , a new type of high-strength, constant-resistance, and large-deformation bolt, which is compatible with figure 1 The technical solutions shown are basically the same, and will not be described again here. The main difference is that the thin section of the cold-drawn rod body 3 has a smooth surface, and the end of the cold-drawn rod body 3 is provided with an external thread 8 for installing the nut 6; Processed with ribs to increase the friction between it and the anchoring agent.

[0054] The usage method of embodiment two is:

[0055] Step 1: Drill the anchor hole in the support roadway, the diameter of the anchor hole matches the diameter of casing 1;

[0056] Step 2: install the casing 1 in the anchor hole towards the bottom of the hole, inject the anchoring agent 11 into the anchor hole, and after the anchoring agent 11 is solidified, put the tray 5 on the outcrop of the cold-drawn rod body 3, tighten the nut 6, and reach Design preload.

Embodiment 3

[0058] combine Figure 4 , a new type of high-strength, constant-resistance, and large-deformation bolt, which is compatible with figure 1 The technical solutions shown are basically the same, and will not be described again here. The main difference is that the thick section and the tapered section of the cold-drawn rod body 3 adopt a hollow structure, and the thin section adopts a solid structure. As the drawing limit of the rod body; the two adopt threaded connection or welding structure.

[0059] In all the above-mentioned embodiments, the casing 1 is a cylindrical steel pipe, its diameter and wall thickness should meet the anchoring force requirements, and its length corresponds to the length of the thick section of the cold-drawn rod body; the casing 1 and the wire drawing die 2 are connected, except for using In addition to the high-strength bolt 7, the available methods also include threaded connection or welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com