Double-acting hydraulic ejecting type vacuumizing and compressing device of double cylinders

A compression device, injection-type technology, applied in the field of machinery, can solve the problem that the compression capacity or vacuuming capacity of the integrated piston vacuum pump and piston air compressor cannot meet the requirements of practical applications, and the piston vacuum pump and piston air compressor cannot meet the actual application requirements. Problems such as the integration of the compressor, the compression capacity of the all-in-one machine or the lack of vacuuming capacity, etc., to achieve the effect of upper air or fast air extraction, simple structure, and tight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

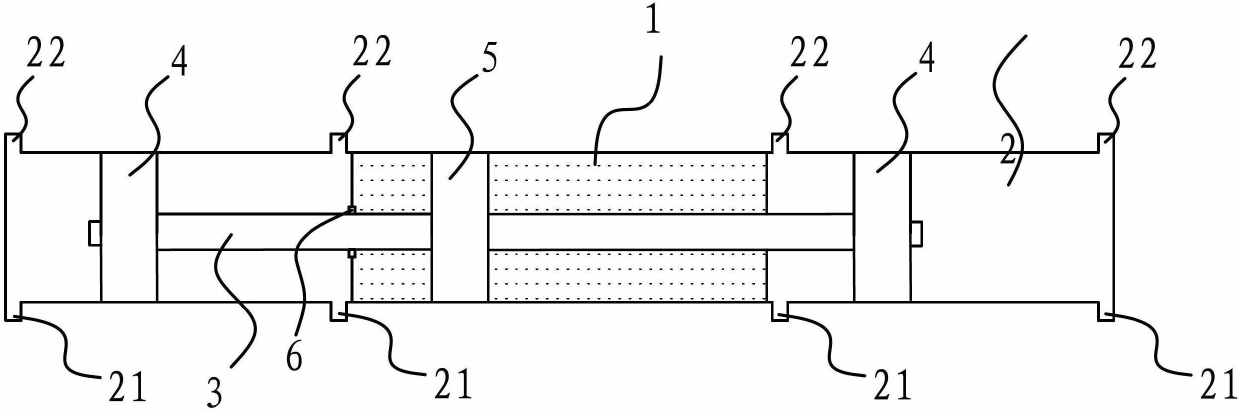

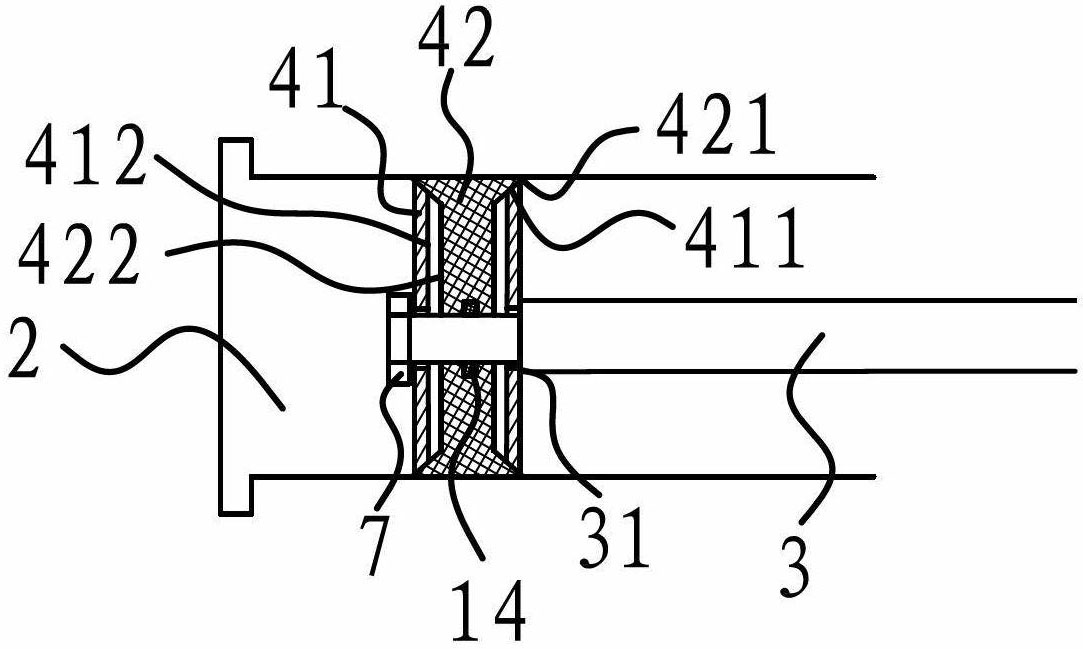

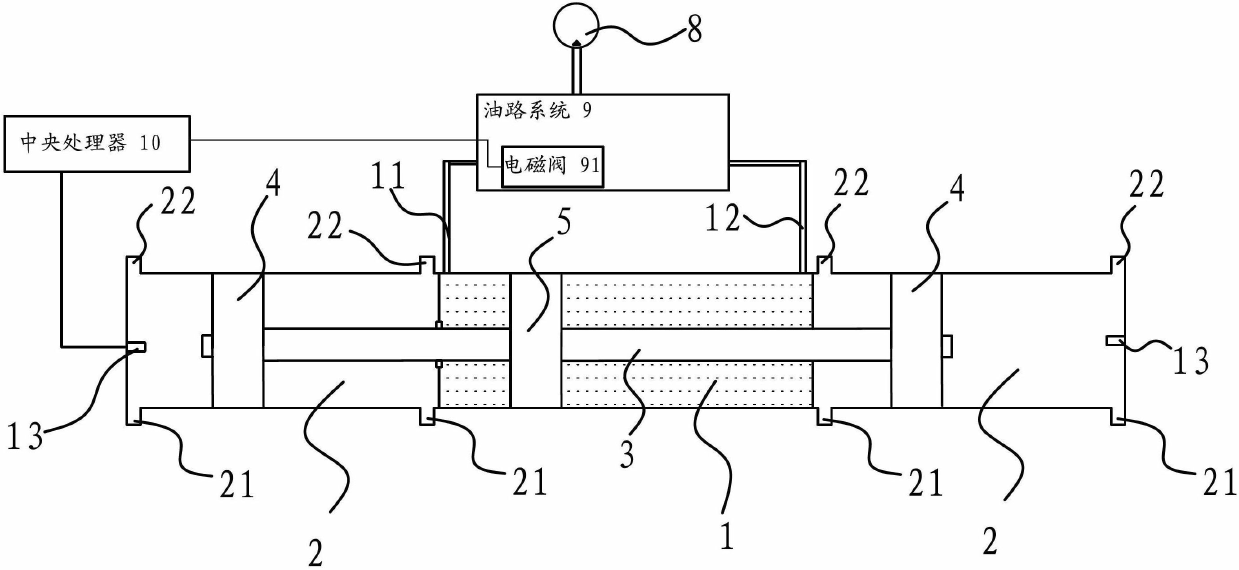

[0027] Such as figure 1 As shown, the vacuuming and compression device of the double-acting hydraulic injection type double cylinder includes a hydraulic cylinder body 1, a cylinder body 2, a double output rod 3, a cylinder piston 4, and a hydraulic cylinder piston 5, as well as a detection mechanism and hydraulic automatic control The mechanism is used to realize the integrated function of air compression and vacuum pumping, and can perform air compression, vacuum pumping, and air compression and vacuum pumping at the same time, so as to realize three functions of one machine and meet the requirements of actual use.

[0028]Specifically, there are two cylinder blocks 2, which are respectively symmetrically connected to the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com