Detachable connecting component and connecting device using same

A technology of connecting components and connecting devices, which is applied in the direction of connecting components, rods, mechanical equipment, etc., can solve the problems of high processing technology and processing accuracy of connecting parts, use efficiency and working environment restrictions, and high processing costs. High installation and disassembly efficiency, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

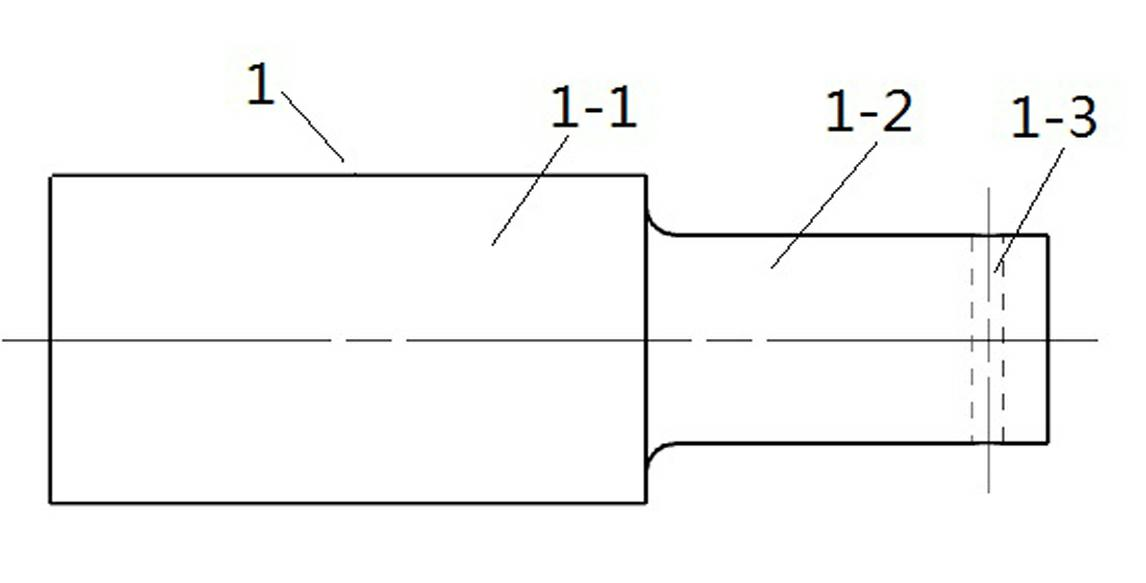

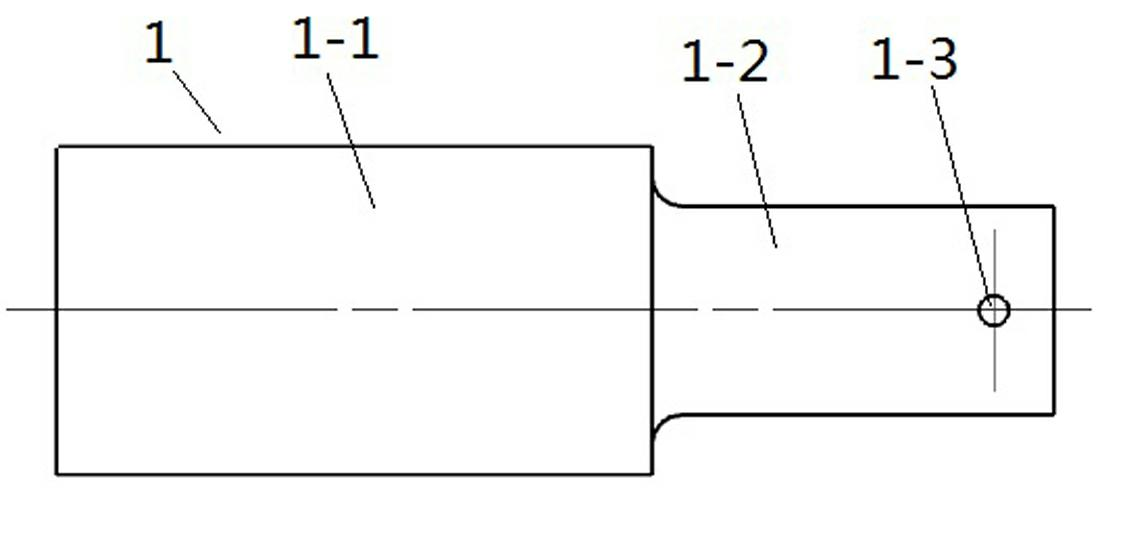

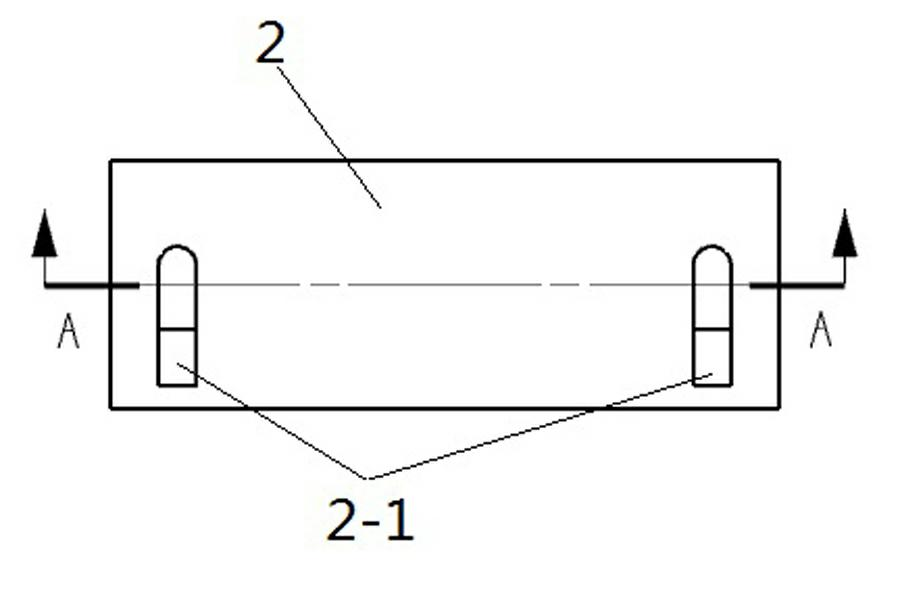

[0027] An example of a coupling device such as Figure 1~9 Shown: including the matching connecting core rod 1 and connecting sleeve 2. The coupling sleeve 2 includes a coupling sleeve inner hole 2-2 arranged at its geometric center, and the coupling sleeve inner hole 2-2 constitutes a coupling cavity. The coupling mandrel 1 includes a coupling base 1-1 and a cylindrical coupling section 1-2 fixedly connected to one end of the coupling base 1-1 and used for rotating and inserting into the inner hole 2-2 of the coupling sleeve during use. The circumference diameter of segment 1-2 is smaller than the outer circumference diameter of coupling seat 1-1. The end of the coupling section 1-2 is provided with a steel wire rope through hole 1-3 that runs through the radial direction of the coupling section 1-2 along the radial direction of the coupling section 1-2. The hole walls at the two ends of the inner hole 2-2 of the connecting sleeve are turned inside out and provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com