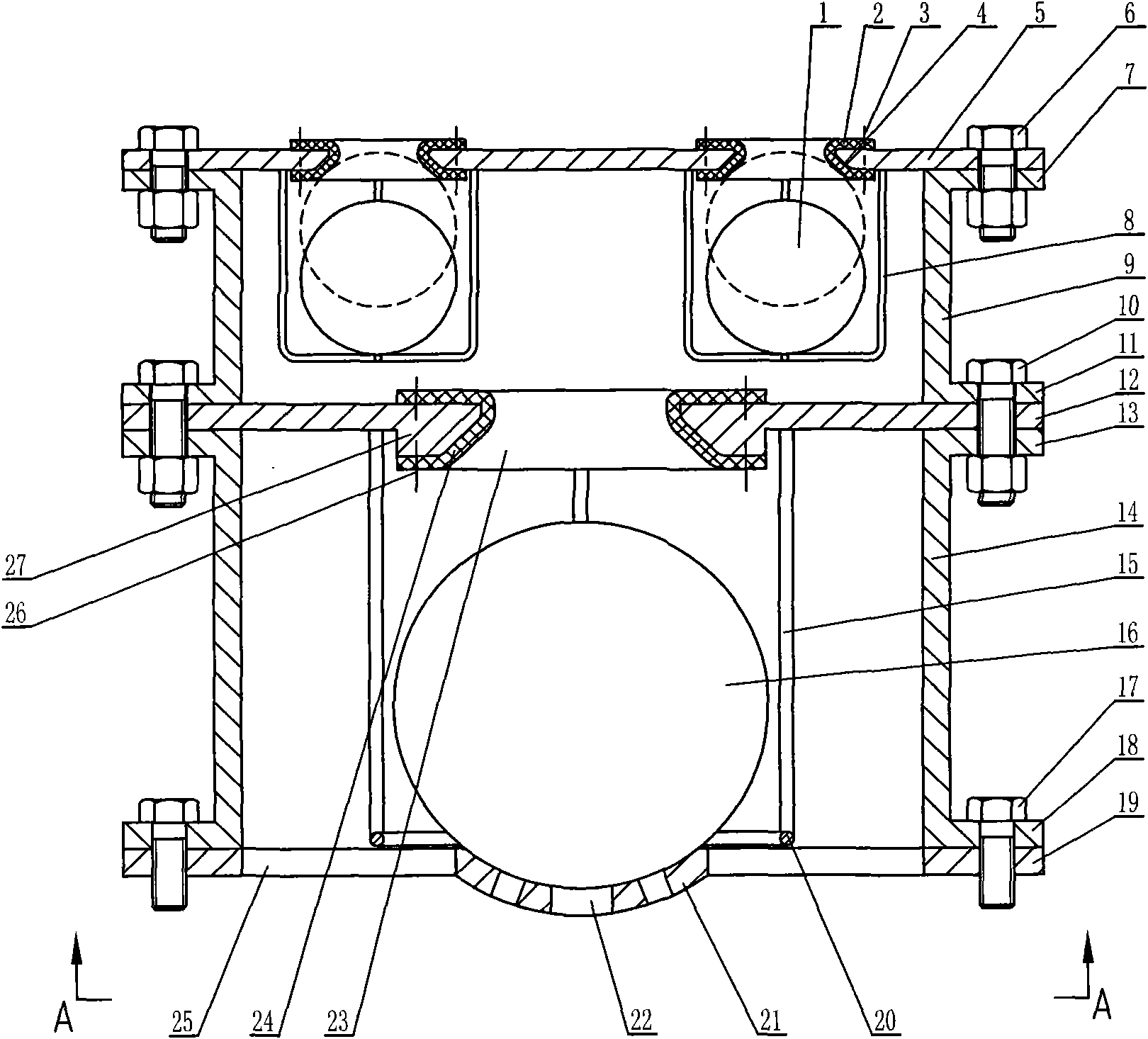

Double-layer floating ball type vacuum breaking valve

A technology of vacuum breaker valve and floating ball type, which is applied in the direction of valve details, multi-way valves, valve devices, etc. It can solve the problems of floating ball deformation, no water hammer resistance, no secondary water return sealing device, etc., and achieve safe operation , long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

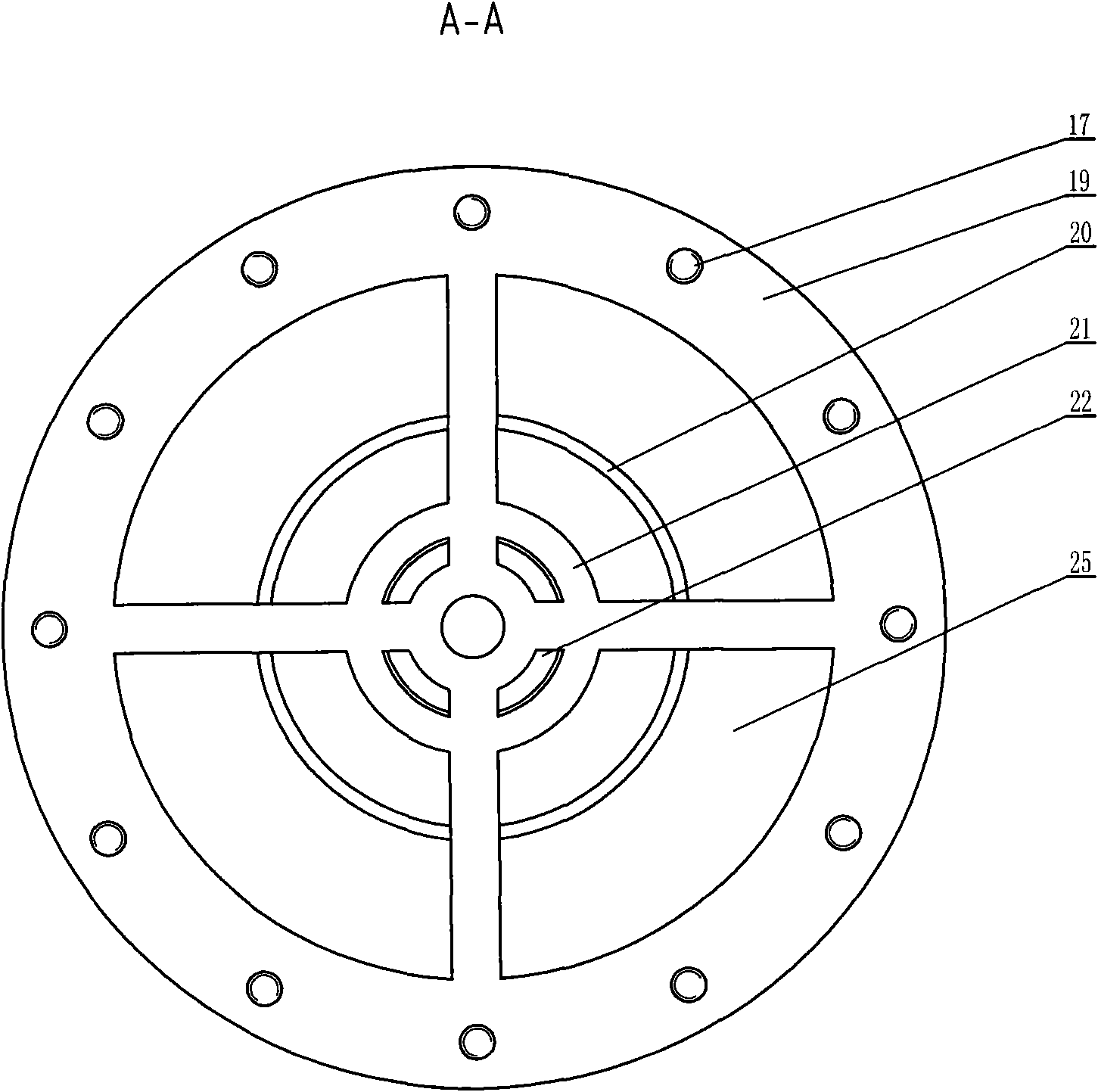

[0018] After putting 4 to 8 upper sealing floats (1) into the upper float basket (8), then fix the upper ends of 4 to 8 upper float baskets (8) to the upper air inlet holes on the upper orifice plate (5) correspondingly (4) Below the position, use the upper hole sealing ring screw (3) to fix the upper air inlet sealing ring (2) in 4 to 8 upper air inlet holes (4), and use the upper fixing bolts (6) to fix the upper orifice plate (5) It is fixed together with the upper flange (7) of the upper cylinder. The lower float basket (15) is fixed on the middle orifice plate (12) that has the middle air inlet (23), and the middle air inlet sealing ring (24) is fixed on the middle air inlet (23) with the middle hole screw (26). 23) on. Put the lower sealing float (16) into the ball holder (21) with the damping hole (22), the ball holder (21) is integrated with the damping orifice plate (19), and there are 4 lower air inlet holes in the middle (25). Insert the lower floating ball baske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com