Method for realizing homogenized control of light beam by utilizing free-form curved lens

A curved lens and light control technology, which is applied in the field of applied optics, can solve the problems of light beam control and complexity of uniform light system, and achieve the effect of limiting effect, good uniformity and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

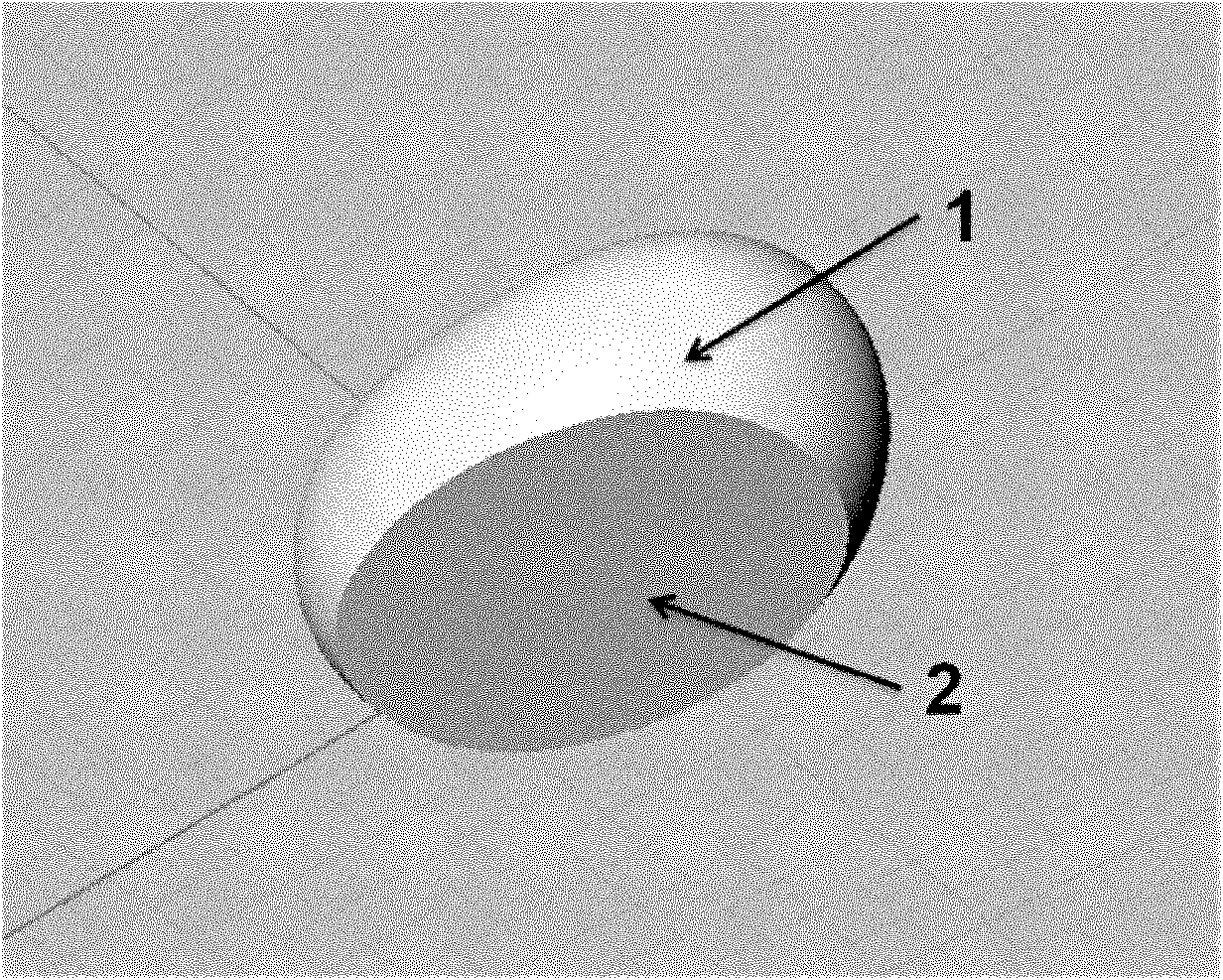

[0033] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

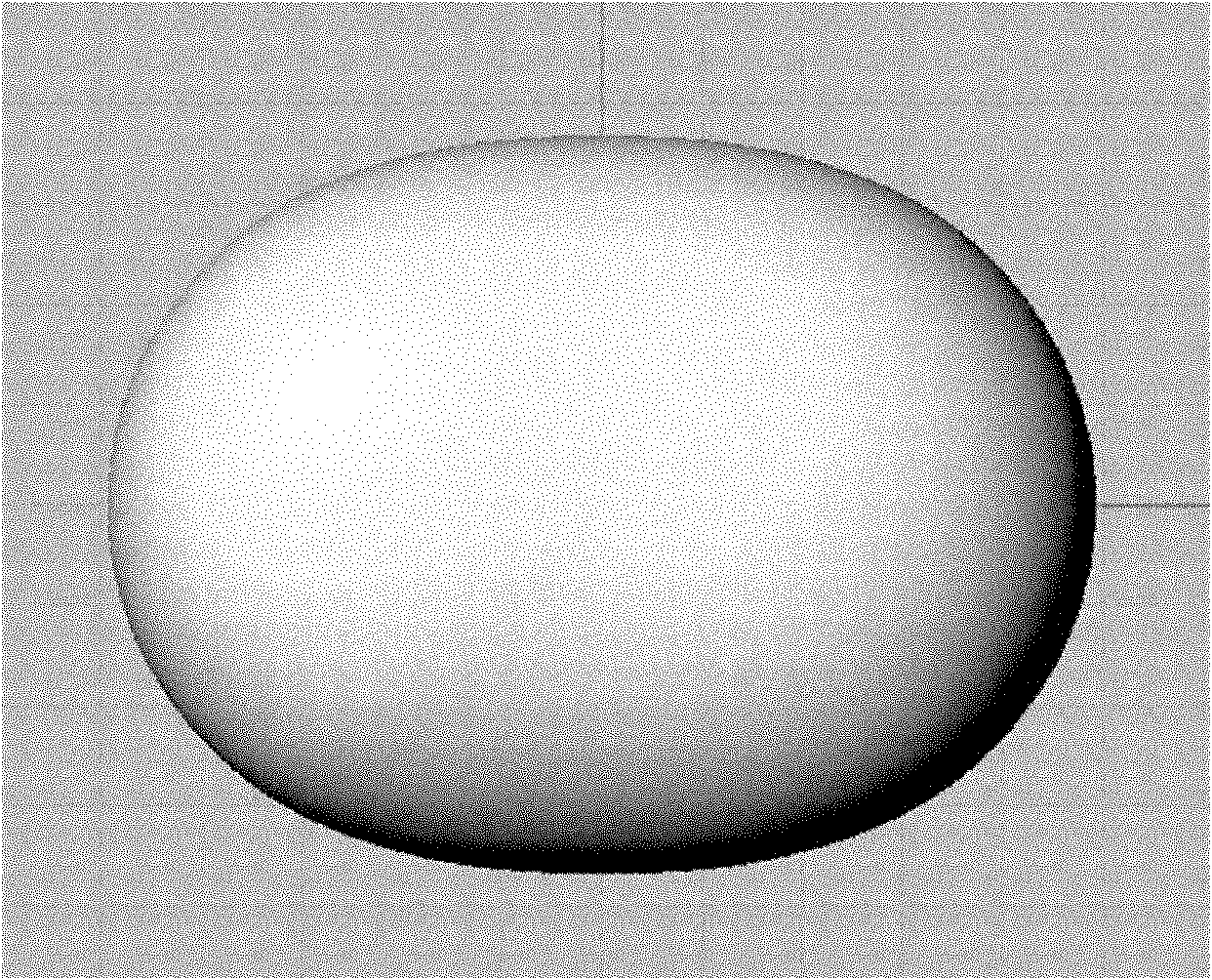

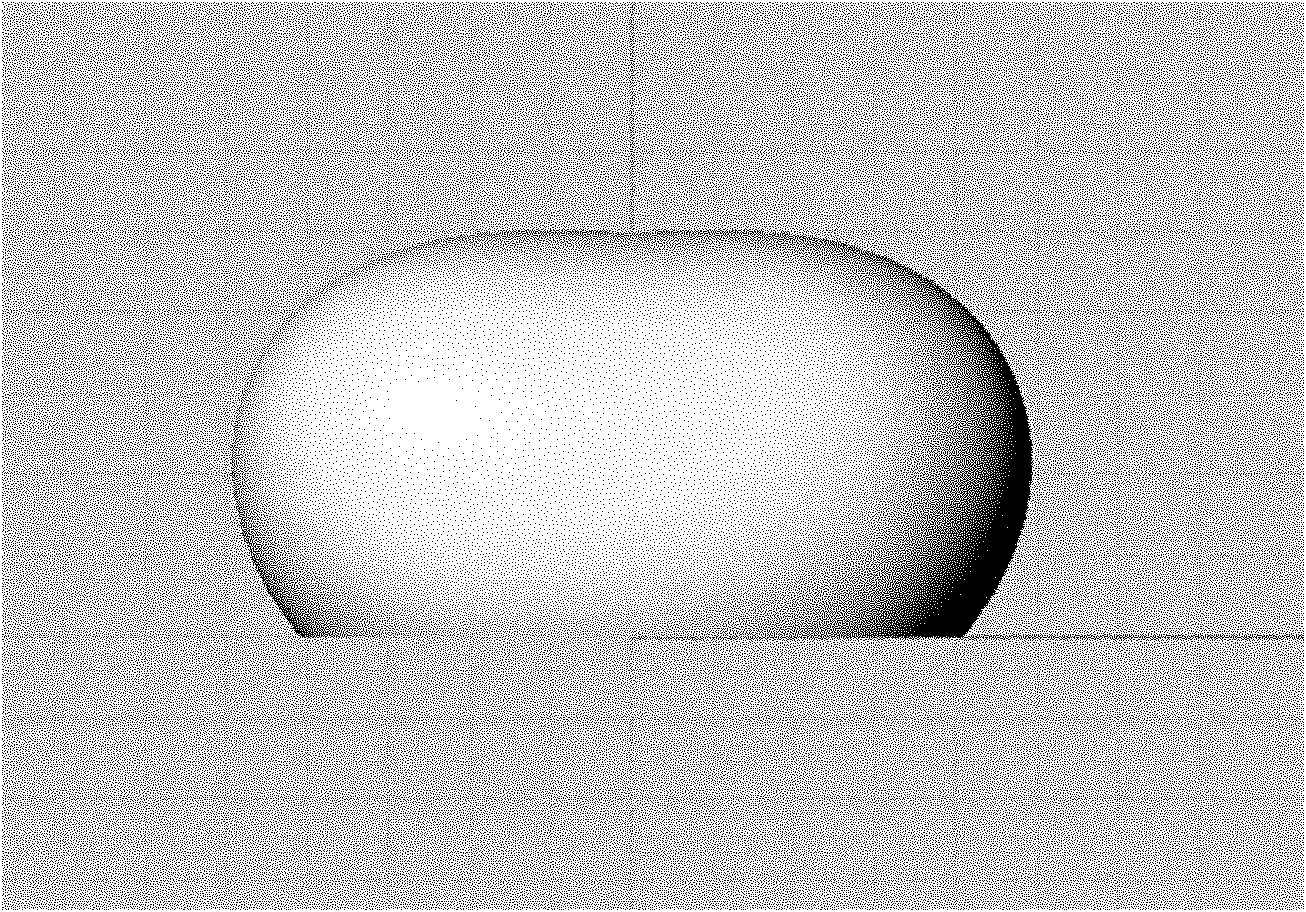

[0034] A method for realizing uniform light beam control by using a free-form surface lens. The method includes the following steps:

[0035] Step 1: According to the provided light source data, determine that the light distribution function of the light source satisfies the Gaussian distribution, with a diameter of 10mm;

[0036] Step 2: Determine the target dodging area as required. This example is rectangular, length a=30mm, width b=16mm, and the distance between the light source and the target area h=10mm;

[0037] Step 3: Select the lens material as PMMA, the refractive index of this material is n=1.49;

[0038] Step 4: Divide the rectangular lighting area into a number of grids passing through the center of the rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com