Spot cutting imaging system

An imaging system and light spot technology, which is applied in the direction of light source fixation, lighting device, and lighting device parts, etc., can solve the problems of limited use of computer lights and limited effect of computer light spot patterns, so as to enrich the effect of light spot patterns and satisfy the The needs of the spot modeling effect, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

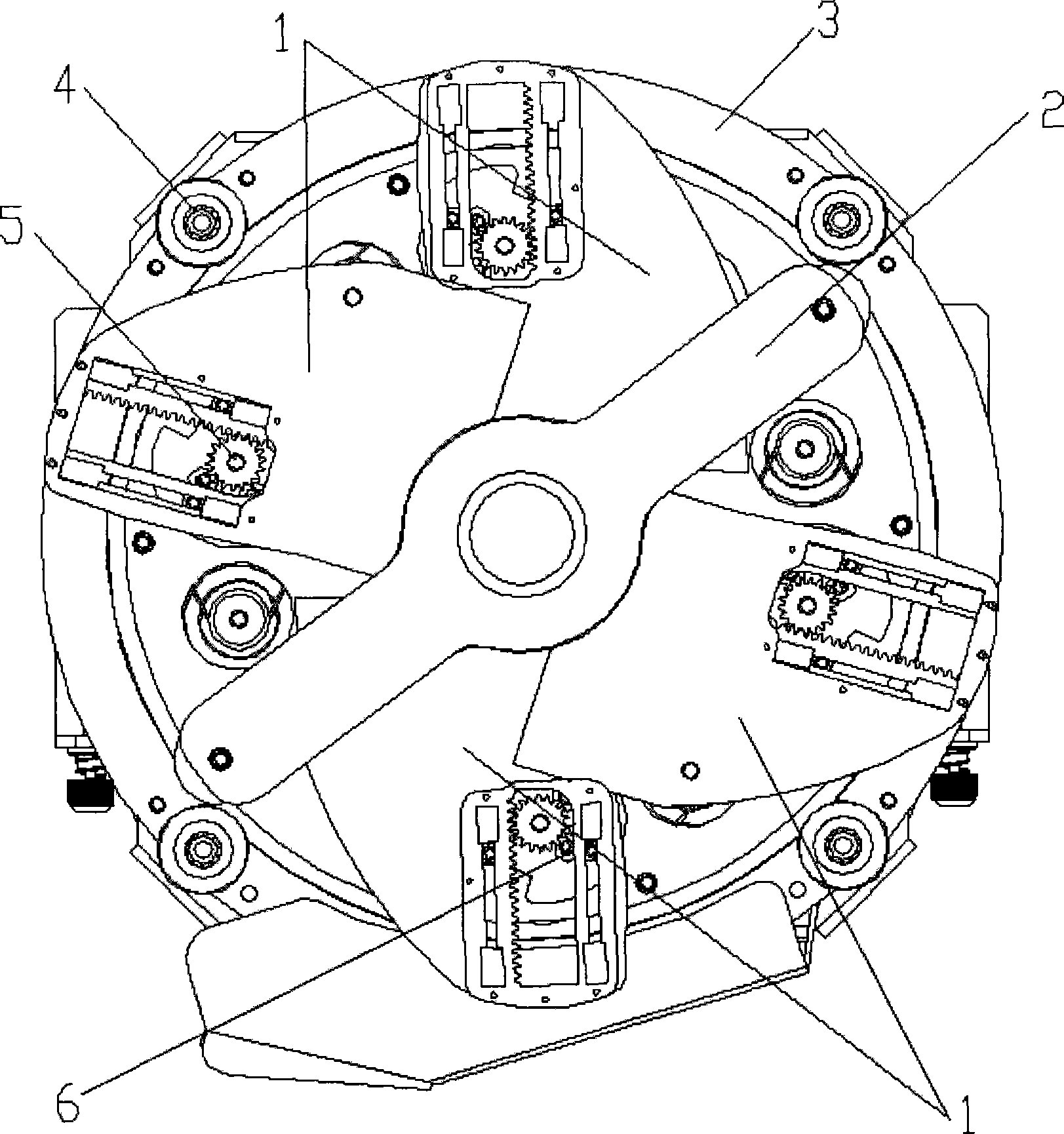

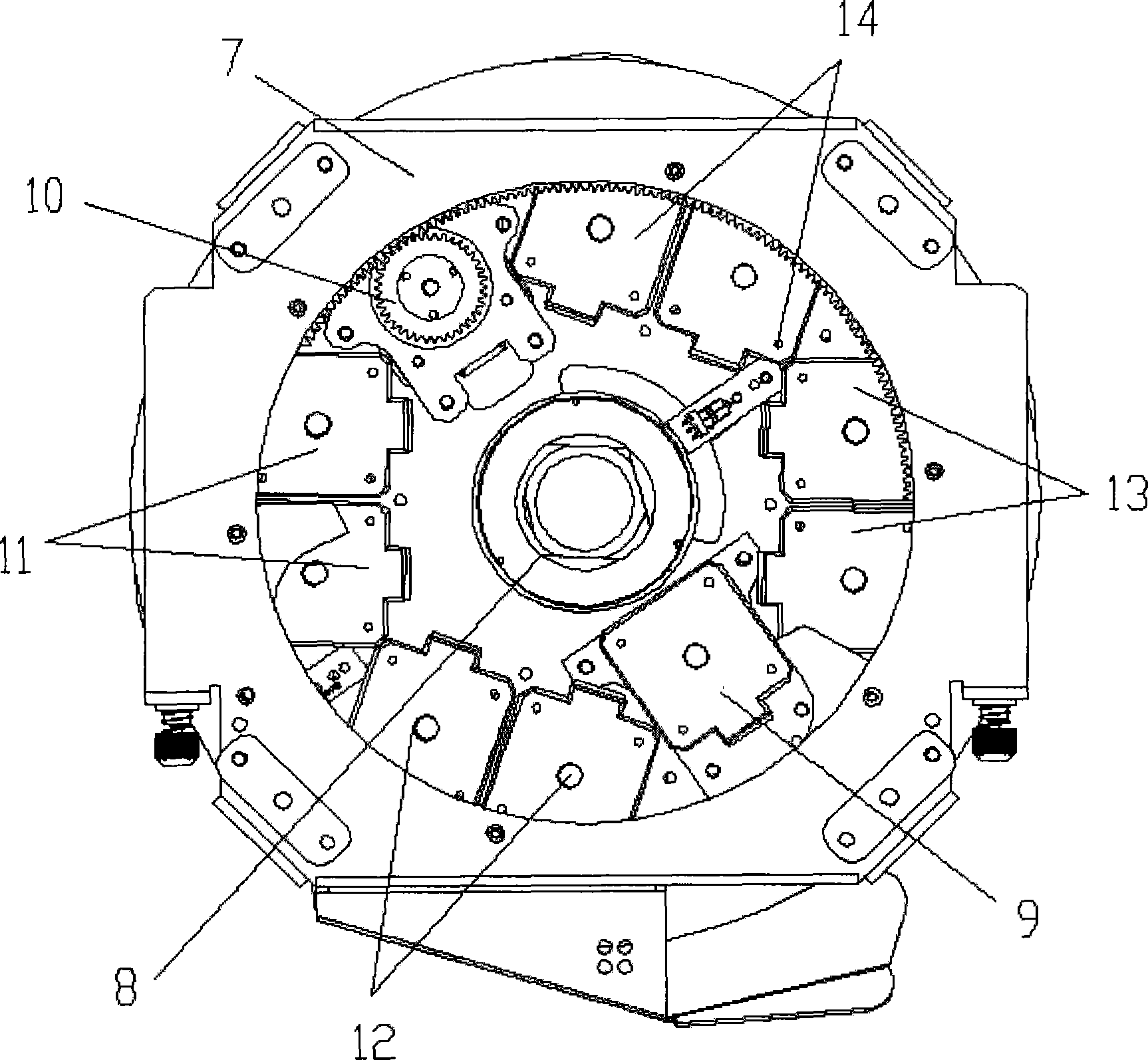

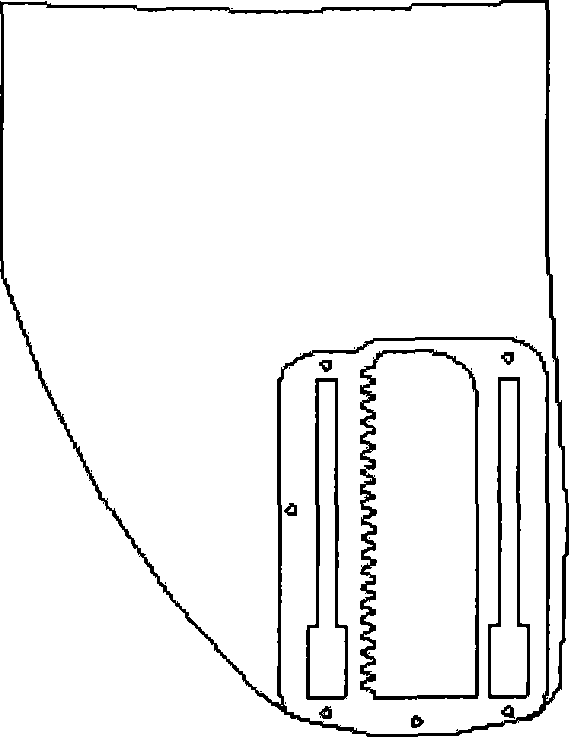

[0026] The invention relates to a light spot cutting imaging system used on a stage lamp. According to an exemplary embodiment of the present invention, as attached figure 1 And attached figure 2 As shown, include: for example 4 fan-shaped light cutting slices (1), grating (8), motor (9), (10), (11), (12), (13), (14) etc. attached image 3 It is a schematic diagram of a light-slicing sheet structure of the present invention. However, obviously, those skilled in the art can understand that the light cutting sheet (1) can not only be fan-shaped, but also can be made into any shape according to actual needs.

[0027] as attached figure 1 And attached figure 2 Shown, the sheet metal support (7) that has rotating wheel (4) is set at the inscribed square four vertices of fixed sheet metal, and rotating wheel (4) is engaged with the chassis of disc (3), and in motor (10) Driven to realize the rotation of the disc (3). The swing of the motor (10) can be effectively blocked by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com