Vacuum heating device for insulating oil

A technology of vacuum heating and insulating oil, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., and can solve the problems of insulating oil cracking, high temperature, and different flow rates of insulating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

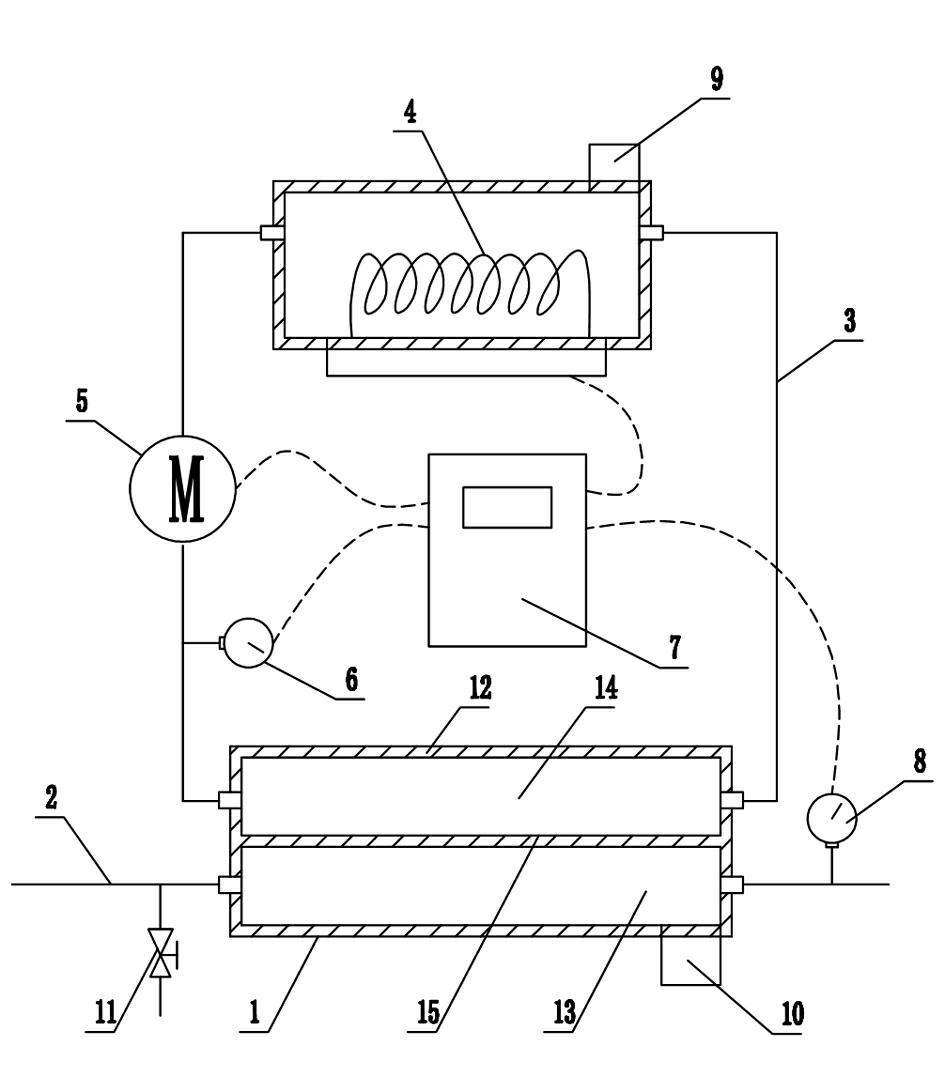

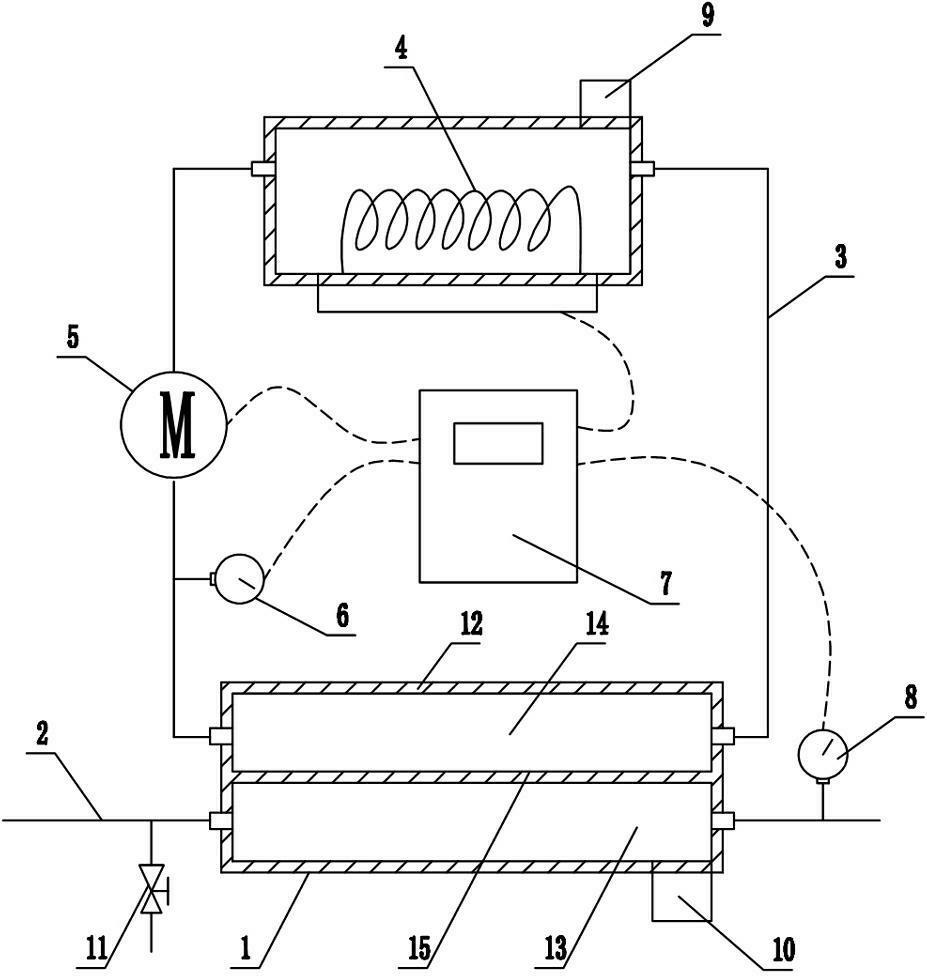

[0023] Such as figure 1 As shown, the insulating oil vacuum heating device mainly includes a heat exchanger 1, the first heat exchange branch of the heat exchanger 1 is connected in series in the insulating oil pipeline 2, and the second heat exchange branch of the heat exchanger 1 is preheated The tube 3 forms a closed circuit, and the preheating tube 3 is equipped with a preheater 4 controlled by the controller 7 to heat the preheating medium in the preheating tube 3, and the preheating tube 3 is also equipped with a The circulating pump 5 and the input end of the second heat exchange branch of the heat exchanger 1 are equipped with a temperature sensor 6 electrically connected to the input end of the controller 7 .

[0024]It includes a heat exchanger 1 with two heat exchange branches, the first heat exchange branch of the heat exchanger 1 is connected in series with the insulating oil pipeline 2, and together with other devices on the insulating oil pipeline 2 forms a flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com