Method for predicting shelf life of tomato product

The technology of a tomato product and a prediction method is applied in the field of shelf life prediction of tomato products, which can solve the problems of reducing the nutritional quality and flavor of food, discoloration of processed products, etc., and achieve the effect of accurate storage safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the shelf-life prediction of cold broken tomato pulp

[0020] (1) Store the cold crushed tomato pulp at 0°C, 25°C and 37°C respectively, and the storage time is 5 months;

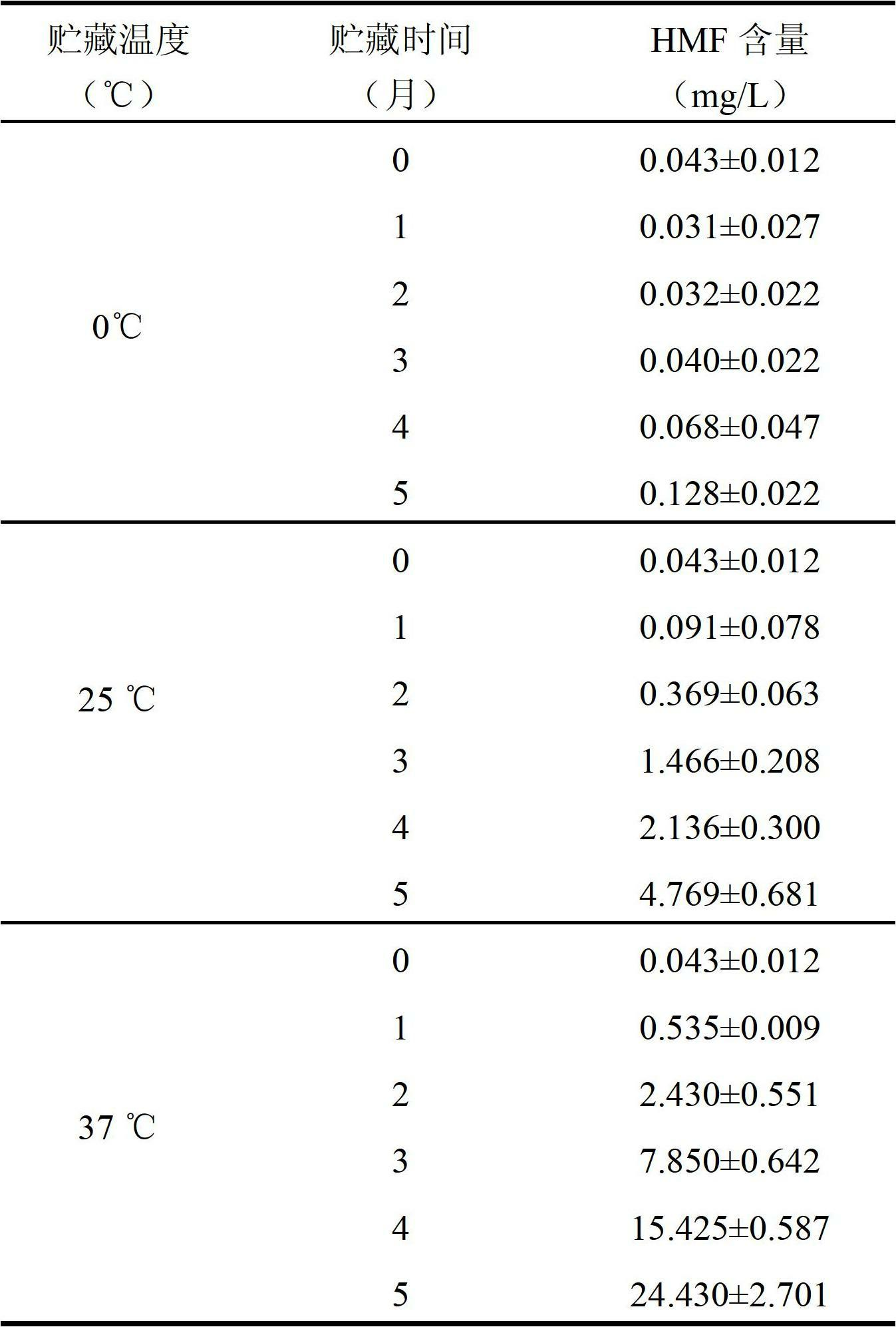

[0021] (2) During the storage period, samples were taken every 30 days to determine the HMF content in the cold crushed tomato pulp. Before the measurement, water was added to the sample to make the content of soluble solids 4.0°Brix. The measurement results are shown in Table 1.

[0022] Table 1 Changes of HMF content in cold crushed tomato pulp during storage

[0023]

[0024] (3) Substituting the above storage time and the HMF content value at each storage time into the formula (a), the kinetic constant k can be obtained 0 and k 1 The value of HMF in cold crushed tomato pulp was obtained, and then the relationship between storage time and HMF content in cold crushed tomato pulp was obtained, as shown in Table 2.

[0025] Table 2 Changes of HMF content with storage time in cold ...

Embodiment 2

[0028] Embodiment 2, the shelf-life prediction of thermal crushing tomato pulp

[0029] (1) Store the hot crushed tomato pulp at 0°C, 25°C and 37°C respectively, and the storage time is 5 months;

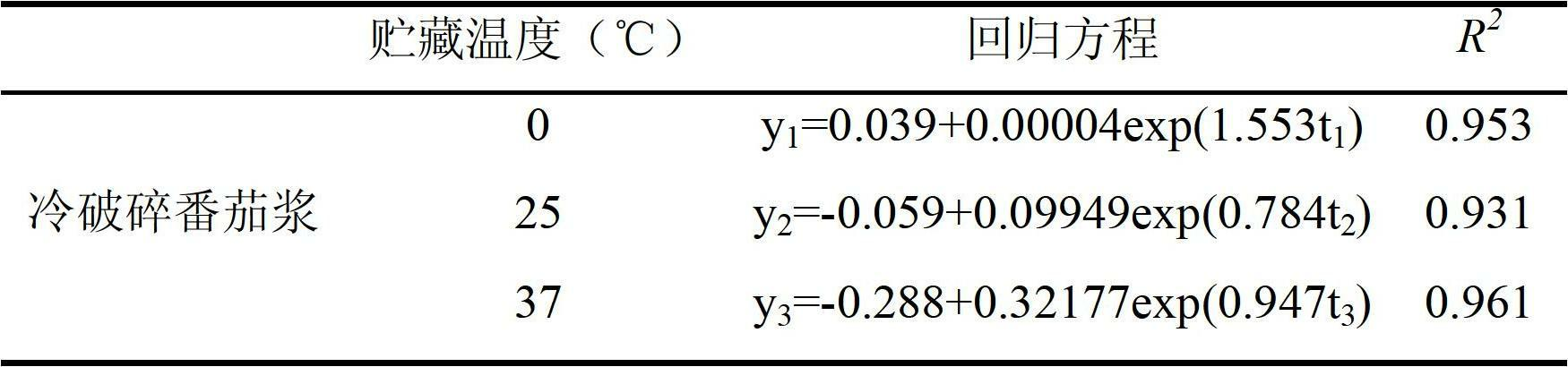

[0030] (2) During the storage period, samples were taken every 30 days to determine the content of HMF in the hot crushed tomato pulp. Before the measurement, water was added to the sample to make the content of soluble solids 4.0°Brix. The measurement results are shown in Table 3.

[0031] Table 3 Changes of HMF content in thermal crushed tomato pulp during storage

[0032]

[0033] (3) Substituting the above storage time and the HMF content value at each storage time into the formula (a), the kinetic constant k can be obtained 0 and k 1 The value of HMF in different storage temperatures was obtained, and then the relationship between storage time and HMF content in hot crushed tomato pulp was obtained, as shown in Table 4.

[0034] Table 4 Changes of HMF content with storage...

Embodiment 3

[0037] The shelf-life prediction of embodiment 3, tomato powder

[0038] (1) Store the tomato powder at 0°C, 25°C and 37°C respectively, and the storage time is 5 months;

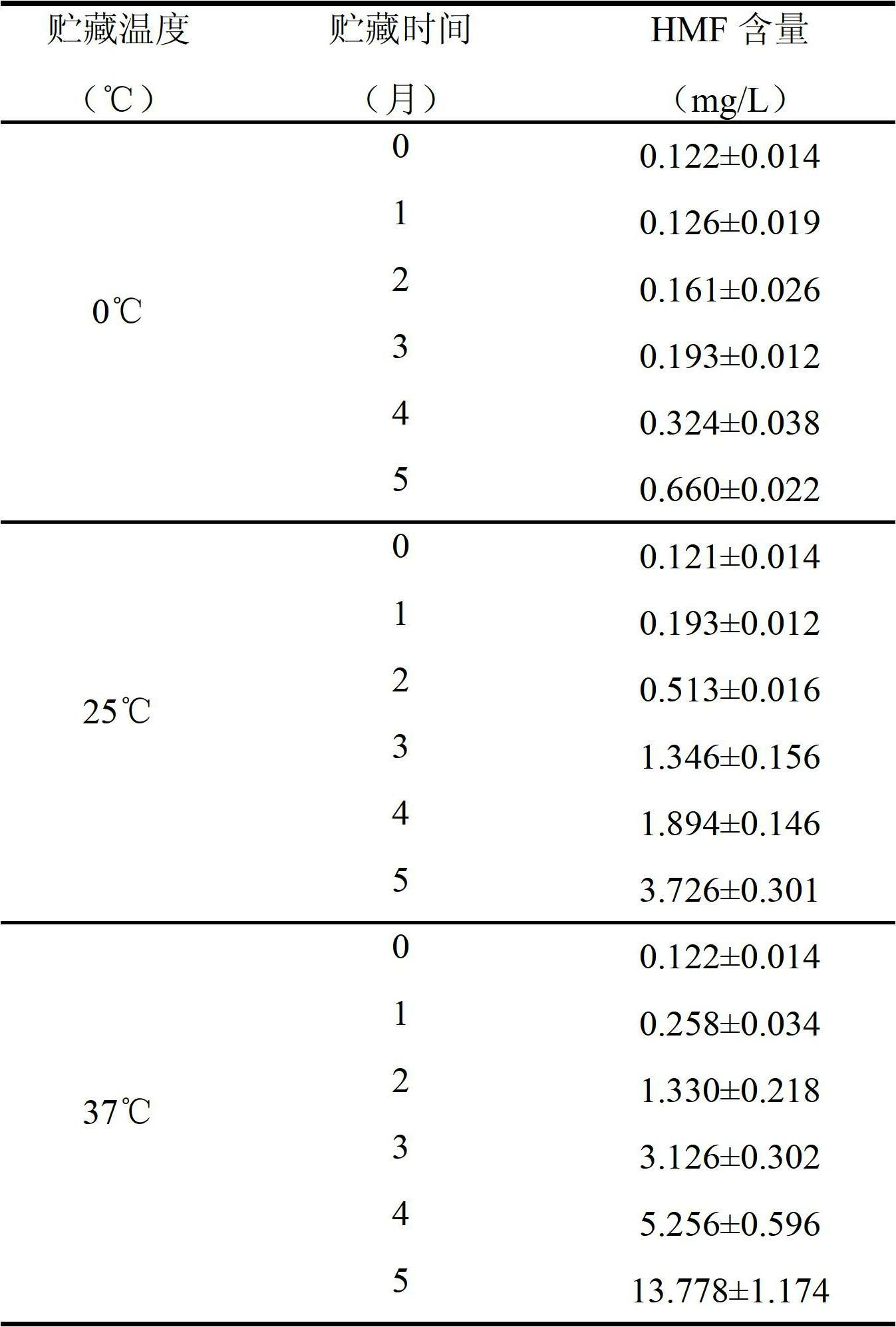

[0039] (2) During the storage period, samples were taken every 30 days to determine the content of HMF in tomato powder. Before the measurement, water was added to the sample to obtain tomato pulp. The content of soluble solids in the tomato pulp was 4.3°Brix, and the measurement results were shown in Table 5. Show.

[0040] Table 5 Changes of HMF content in tomato powder during storage

[0041]

[0042]

[0043] (3) Substituting the above storage time and the HMF content value at each storage time into the formula (a), the kinetic constant k can be obtained 0 and k 1 The value of HMF in tomato powder was obtained, and then the relationship between storage time and HMF content in tomato powder was obtained under different storage temperatures, as shown in Table 6.

[0044] Table 6 Relationship bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com