Color image forming apparatus

A color image, intermediate transfer unit technology, applied in the direction of electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, electric recording technique, etc. become a hindrance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

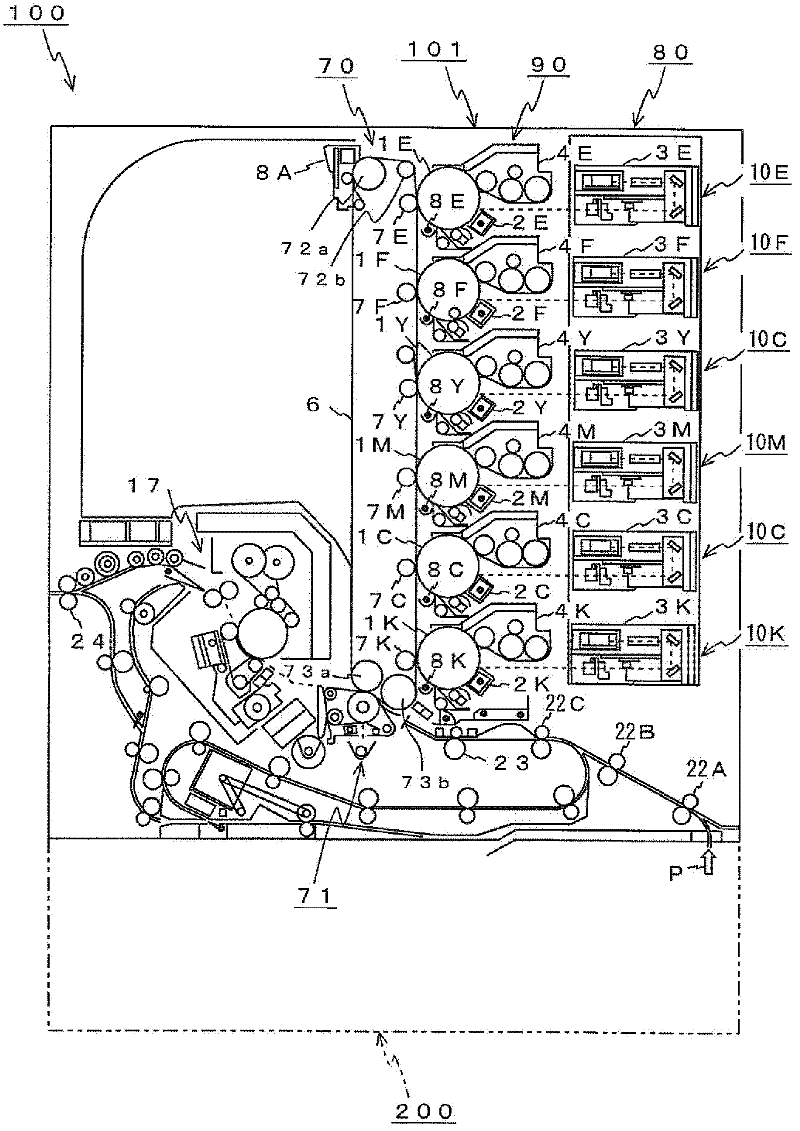

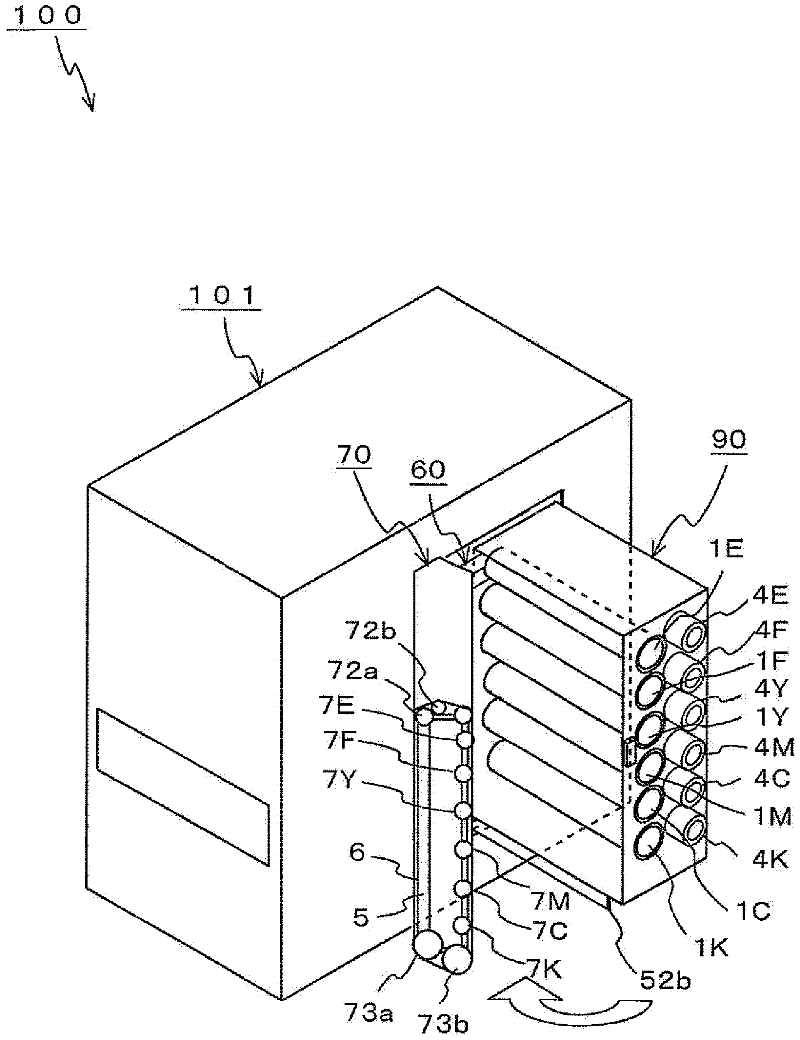

[0119] refer to figure 2 , an example of opening and closing of the intermediate transfer unit 70 according to the first embodiment will be described. In this embodiment, the intermediate transfer unit 70 has a structure that can be inserted into and removed from the apparatus main body 101 together with the processing rack unit 90 , and can be vertically positioned relative to the processing rack unit 90 in a door-like manner. Opening and closing.

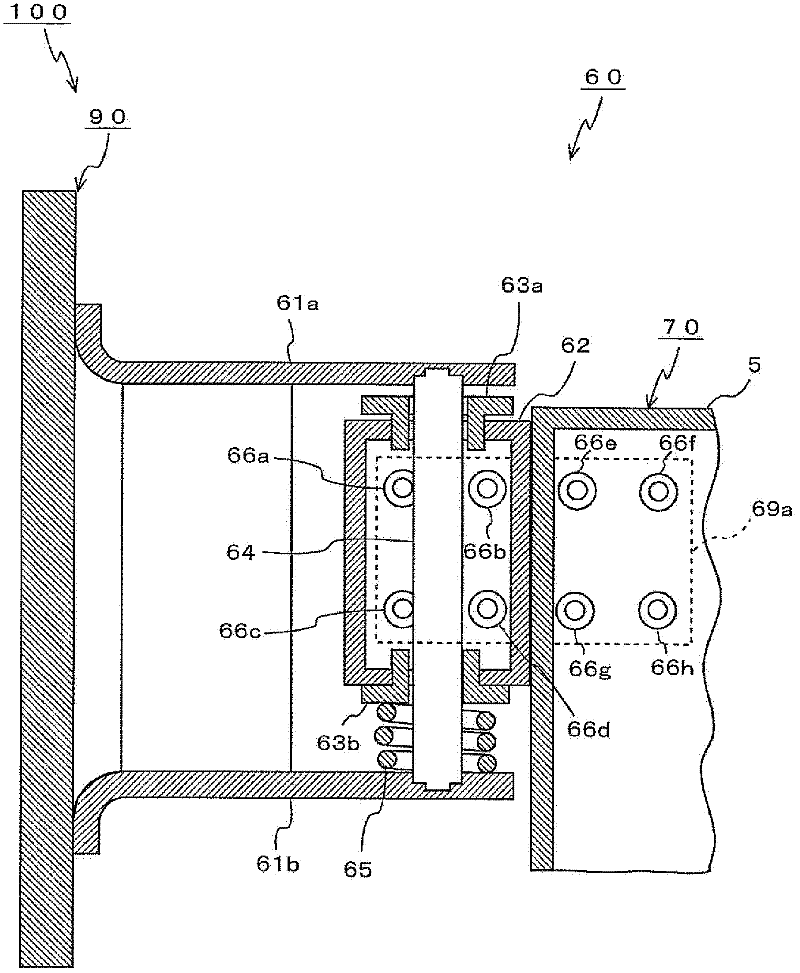

[0120] figure 2 The illustrated intermediate transfer unit 70 is adjacent to the processing rack unit 90 , and is disposed near the approximate center of the apparatus main body 101 when viewed from the front side. The intermediate transfer unit 70 is mounted so as to be freely openable and closable in a vertical door shape via a rotary hinge portion 60 provided on the rear side (rear side) of the process rack unit 90 . The rotary hinge portion 60 constitutes a fulcrum of rotation between the intermediate transfer unit 70 and...

Embodiment 2

[0156] Next, refer to Figure 10-12 The temporary fixing mechanism 20 in the color printer 100 according to the second embodiment will be described. for Figure 10 In the color printer 100 shown, the intermediate transfer unit 70 has a structure that can be inserted and removed from the device main body 101 together with the processing stand unit 90, and can be opened and closed in a vertical state in the form of a door. A temporary fixing mechanism 20 is provided between the bracket unit 90 and the intermediate transfer unit 70 .

[0157] The temporary fixing mechanism 20 is arranged, for example, near the approximate center of the composite unit 201 in a state where the intermediate transfer unit 70 is closed with respect to the process rack unit 90 . In this example, in the state where the intermediate transfer unit 70 is closed relative to the processing rack unit 90, the temporary fixing mechanism 20 is disposed on the boundary line formed between one end of the transfe...

Embodiment 3

[0170] Next, refer to Figures 13 to 17 , the stopper connecting mechanism 30 in the color printer 100 according to the third embodiment will be described. In this example, when the intermediate transfer unit 70 described in the first to second embodiments is opened, the pressing member 31 is rotated by applying the rotational force of the rotary hinge portion 603, whereby the pressing member 31 is moved from the device The position where the main body portion 101 interferes and the position where the intermediate transfer belt 6 is included protrudes.

[0171] Figure 13 The color printer 100 shown in A includes, in addition to the intermediate transfer unit 70 described in the first to second embodiments, a pressing member 31 and a stopper connection mechanism 30 constituting an example of a first connection mechanism. The stopper connection mechanism 30 has rotation transmission gears 32, 34, gear fixing pins 33, 35, arm support bearings 36, 38, and an arm support shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com