LED (Light Emitting Diode) dot matrix display screen

A display screen and LED chip technology, applied in the field of display screens, can solve the problems of poor heat dissipation of LED dot matrix, low luminous efficiency, short heat dissipation path, etc., and achieve the effects of convenient standardized production, good heat dissipation effect, and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

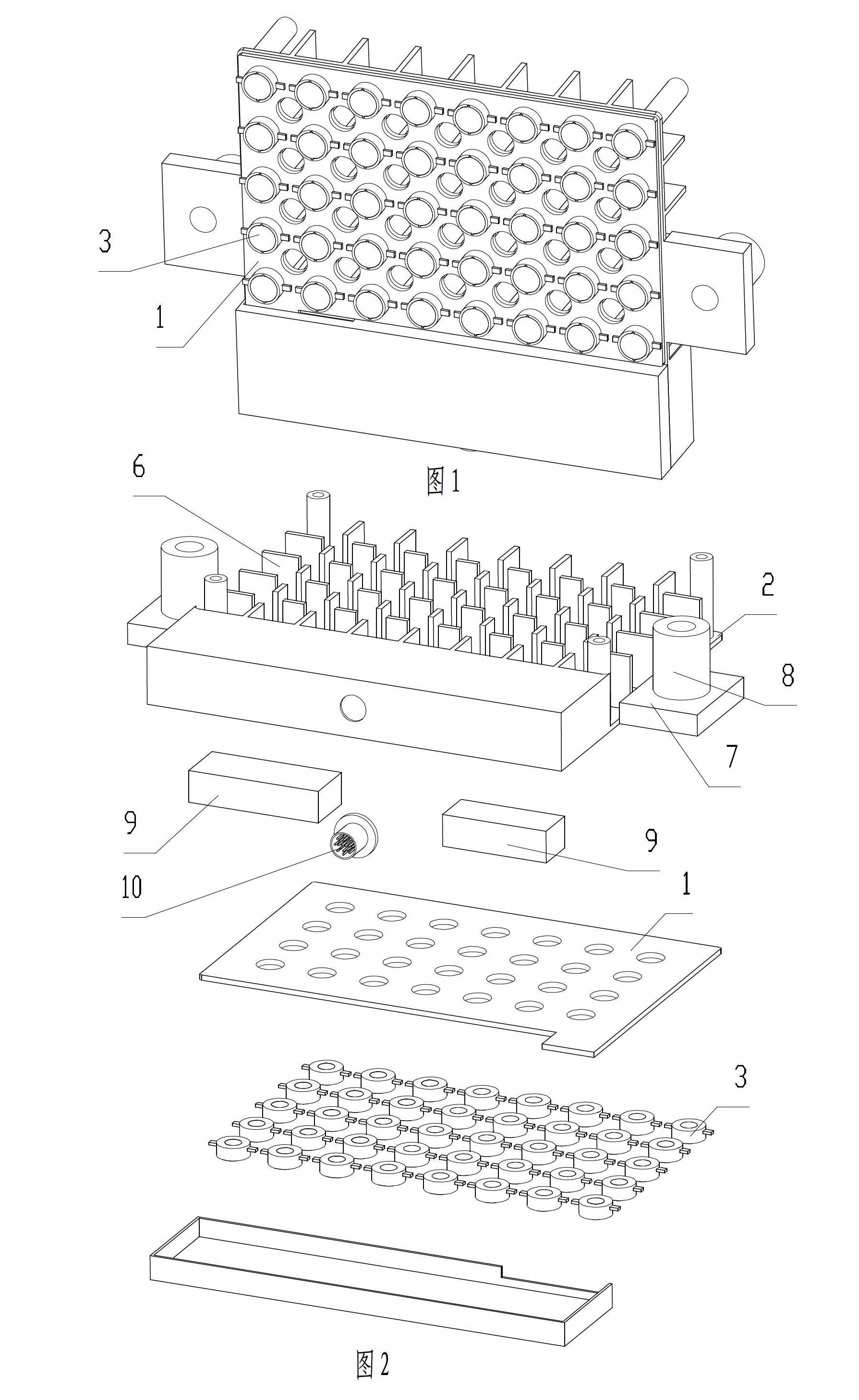

[0046] like Figures 1 to 3 As shown, an LED dot-matrix display screen includes a heat-dissipating PCB substrate 1, a heat-dissipating substrate 2, integrated circuit components (not shown), and a uniform array of LED lamp beads 3, and each LED lamp bead 3 contains only one LED chip , electrically connecting the layout circuit conductive layer (not shown) of the positive and negative pins of the LED lamp bead 3 , the electric control device 9 and the data interface 10 . The LED lamp bead 3 is fixed on the heat dissipation PCB substrate 1, the conductive layer of the layout circuit is arranged on the surface of the heat dissipation PCB substrate 1 on which the lamp bead 3 is fixed, and the integrated circuit components are arranged on the heat dissipation PCB substrate 1 and the fixed LED lamp bead 3 phase. back face. The surface of the heat dissipation PCB substrate 1 facing away from the LED lamp bead 3 is attached and fixed to the heat dissipation substrate 2 . At the cent...

Embodiment 2

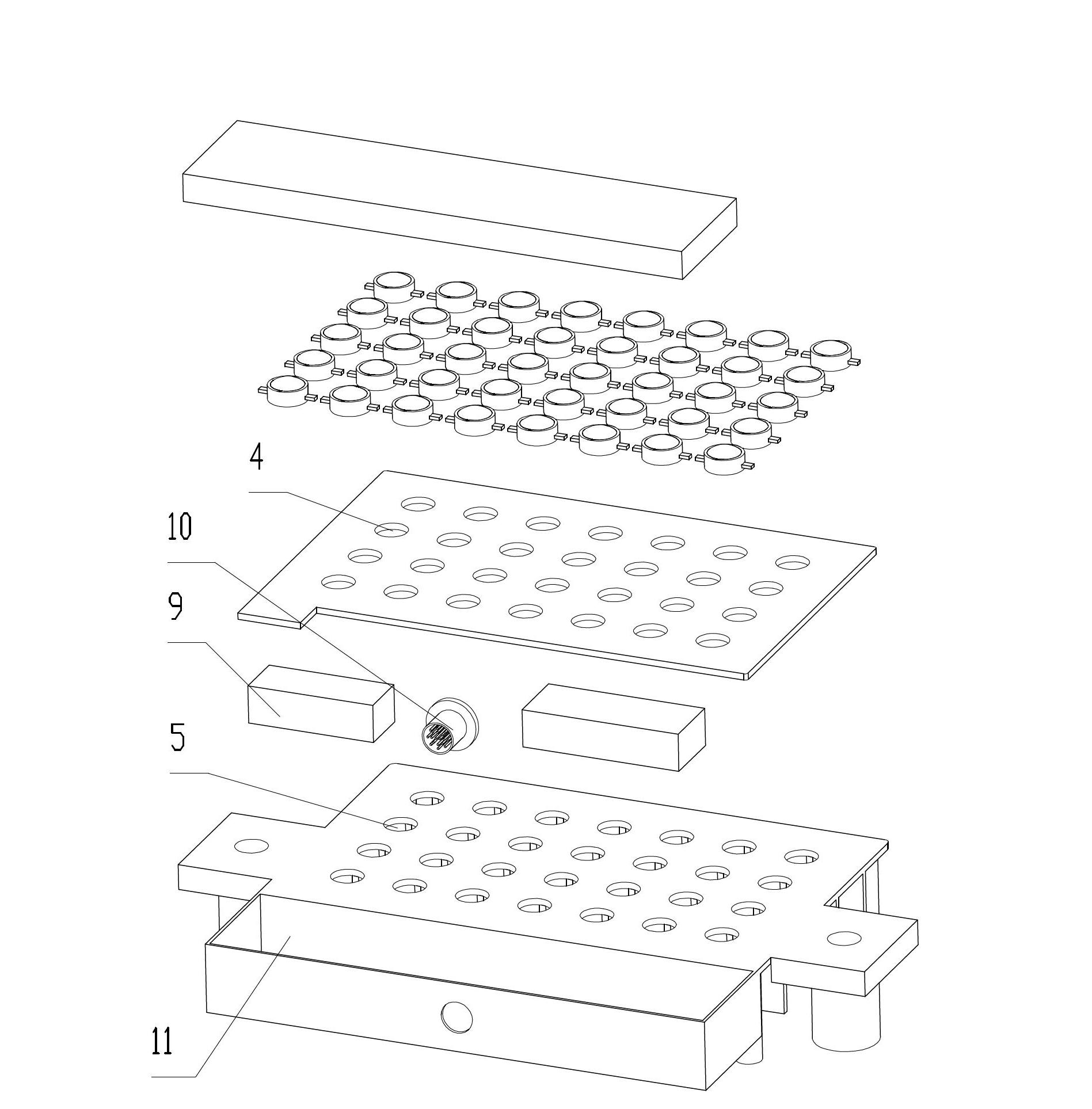

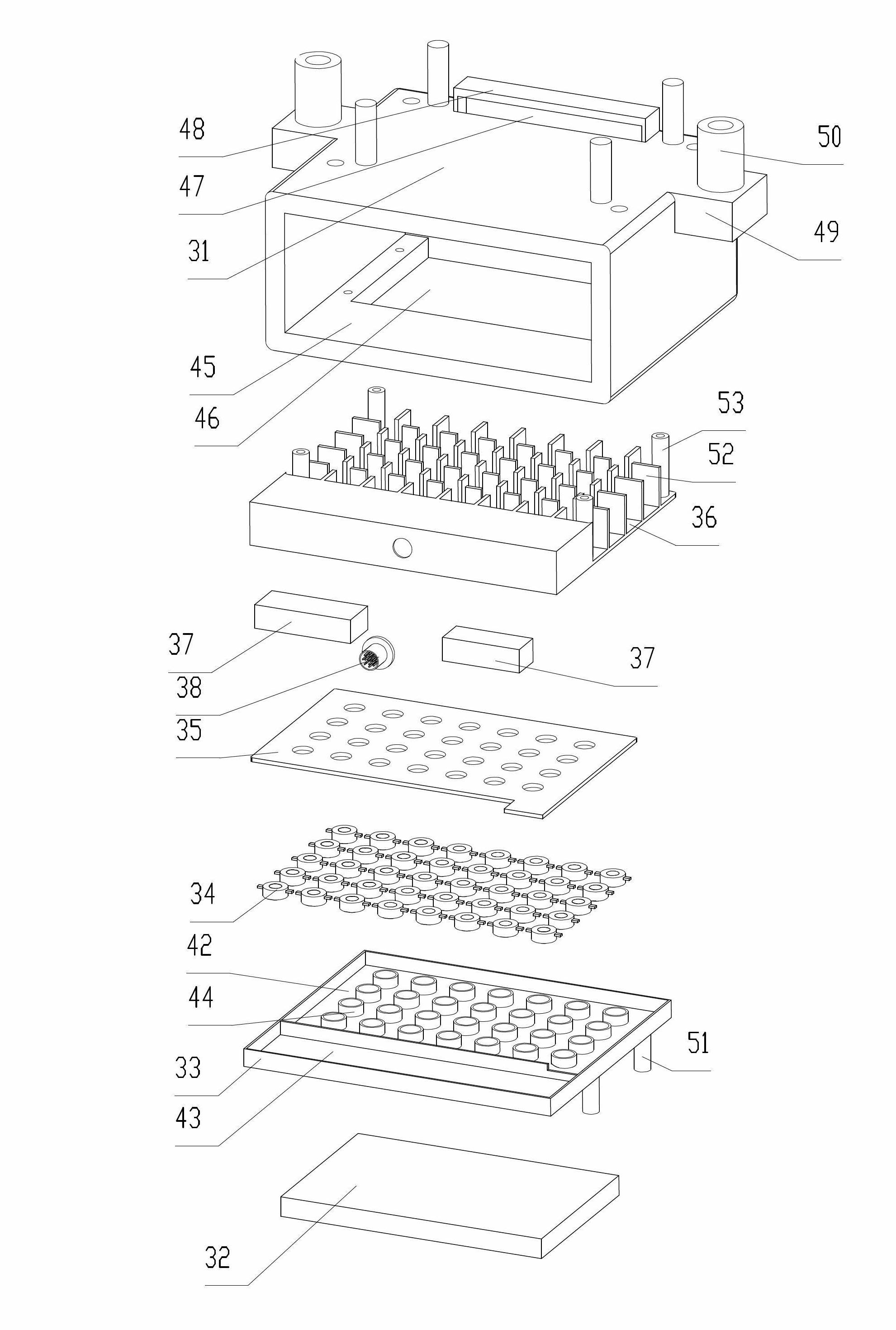

[0049] like Figures 4 to 6 As shown, an LED dot-matrix display screen includes a display frame 31, a light-transmitting sealing plate 32, a light-transmitting cover 33, a uniform array of LED lamp beads 34, a heat-dissipating PCB substrate 35, and a heat-dissipating substrate 36. The integration of control and drive Circuit components (not shown), a layout circuit conductive layer (not shown) electrically connected to the positive and negative pins of the LED lamp bead 34 , the electric control device 37 , and the data interface 38 . The LED lamp bead 34 is fixed on the heat dissipation PCB substrate 35, the conductive layer of the layout circuit is arranged on the surface of the heat dissipation PCB substrate 35 on which the lamp bead 34 is fixed, and the integrated circuit components are arranged on the heat dissipation PCB substrate 35 and the fixed LED lamp bead 34 phase. back face. The surface of the heat dissipation PCB substrate 35 provided with integrated circuit com...

Embodiment 3

[0053] Such as Figure 7 to Figure 9 As shown, an LED dot-matrix display screen includes a light-transmitting cover 60, a plastic plate 61 for positioning the lens, a PCB board 62, a heat dissipation base 63, a flow channel cover plate 64, an LED light-emitting unit, and a cloth electrically connected to the LED light-emitting unit. The conductive layer of the layout circuit (not shown), the integrated circuit components for control and driving (not shown), the electric control device 65 electrically connected with the external power supply and the conductive layer of the layout circuit, and a data interface 66 . Each LED light-emitting unit includes an LED chip 67, a lens 68, and a gold wire 69 electrically connecting the LED chip 67 and the conductive layer of the layout circuit.

[0054] The heat dissipation base 63 includes a bottom plate 70 , and a plurality of chip fixing bosses 71 protruding from the bottom plate 70 integrally formed with the heat dissipation base 63 , ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap