Method for producing silicon avalanche rectifier diode for primary welding automobile

A rectifier diode, welding molding technology, applied in the direction of electrical components, electrical solid devices, semiconductor/solid device manufacturing, etc., can solve the problems of easy falling off of leads and tube cores, decreased reliability, increased thermal resistance, etc., to improve product quality Reliability and adaptability, high equivalent working junction temperature, and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

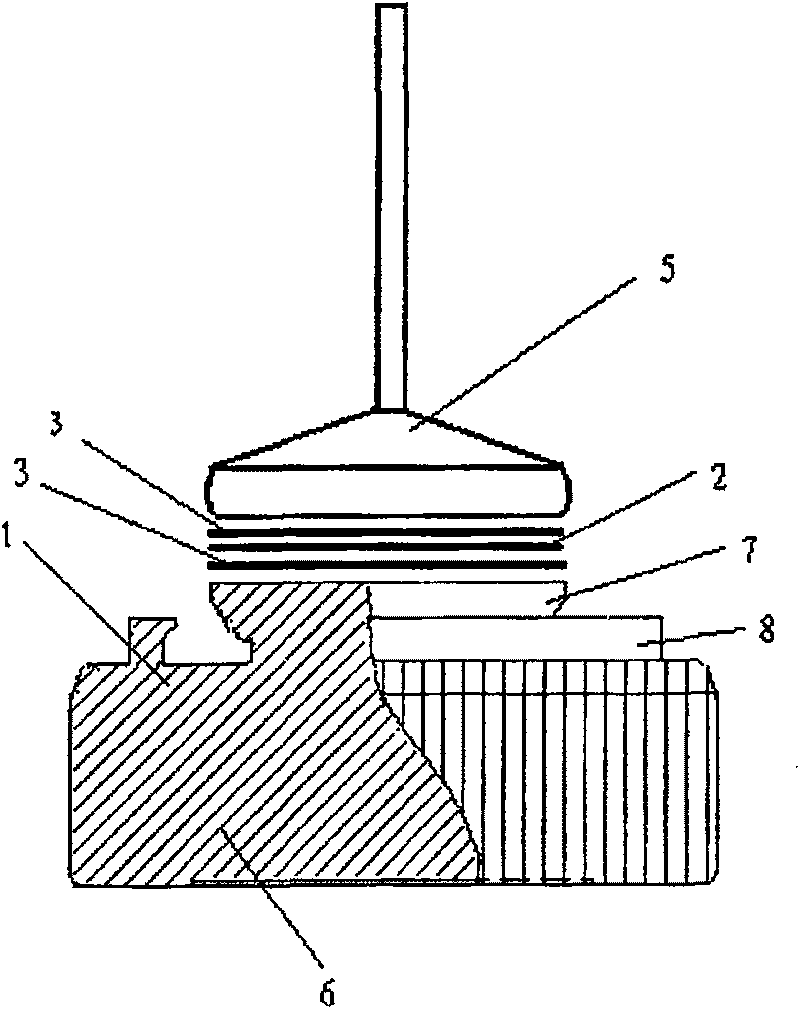

[0023] The production method of the silicon avalanche rectifier diode for motor vehicles of one-time welding formation of the present invention comprises the following steps:

[0024] 1) The lead wire 5, the soldering piece 3, the silicon chip 2, another soldering piece 3 and the base 1 are sequentially combined through one welding to directly make a rectifier diode;

[0025] 2) Pickling the exposed PN junction surface by wet acid etching;

[0026] 3) Use polyimide material to passivate the PN junction surface;

[0027] 4) Encapsulation.

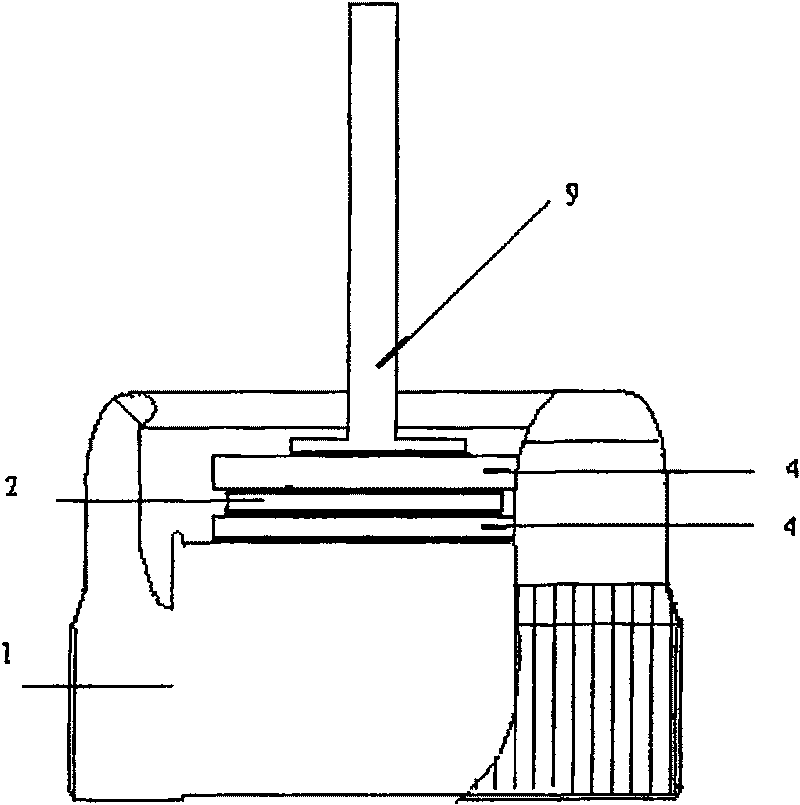

[0028] There are obvious differences in the product structure produced by the primary welding and secondary welding production processes. figure 1 Schematic diagram of the structure of a silicon rectifier diode for motor vehicles produced by the secondary welding process; the diode includes a base 1 on which copper particles 4, silicon chips 2, a second copper particle 4 and split Lead 9.

[0029] figure 2 It is a schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com