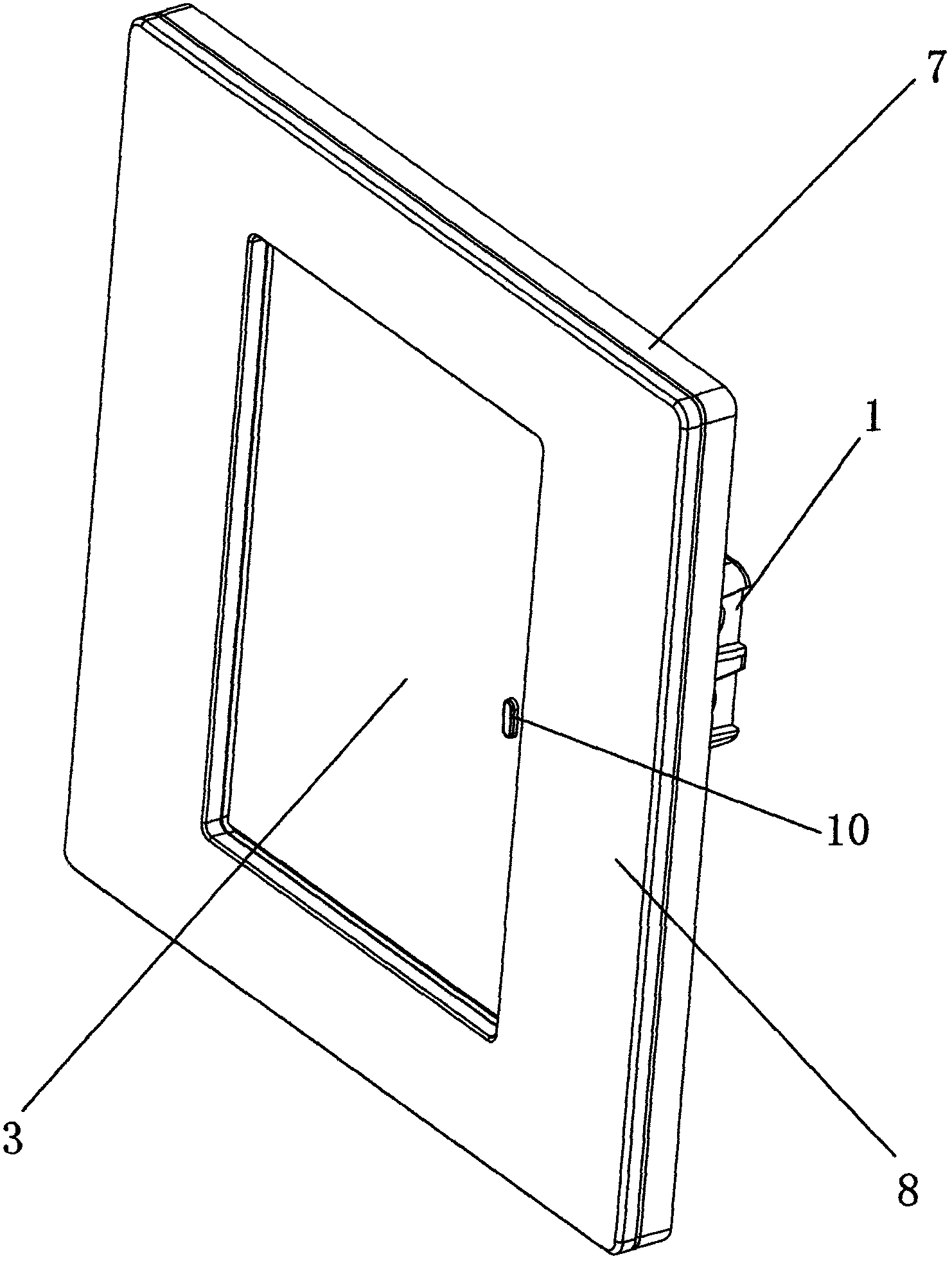

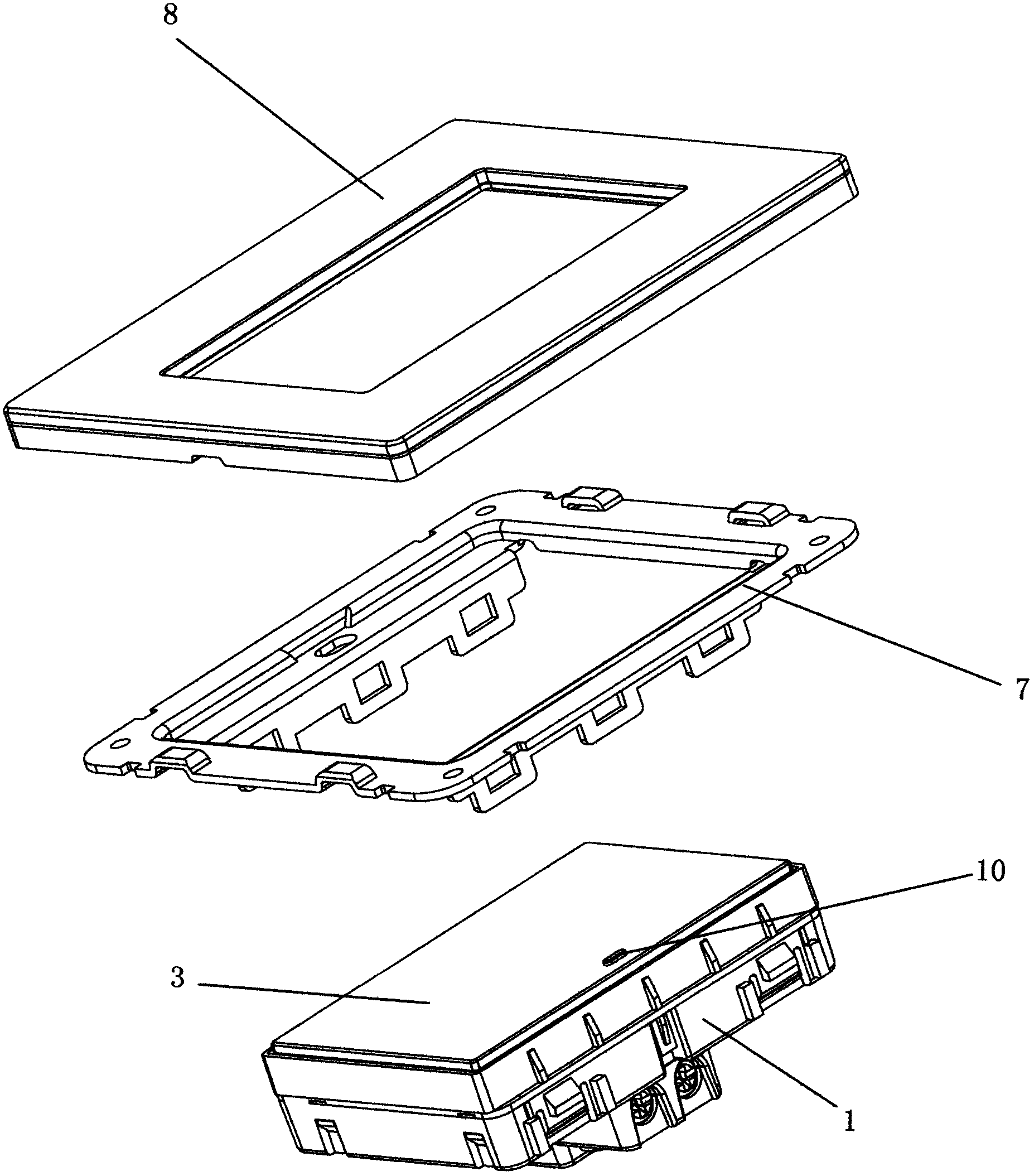

Arbitrary point-pressing panel switch

A flat switch, arbitrary point technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of upturning, uneven force on the switch button panel, and reduce the sensitivity and reliability of the flat switch, so as to ensure the sensitivity , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

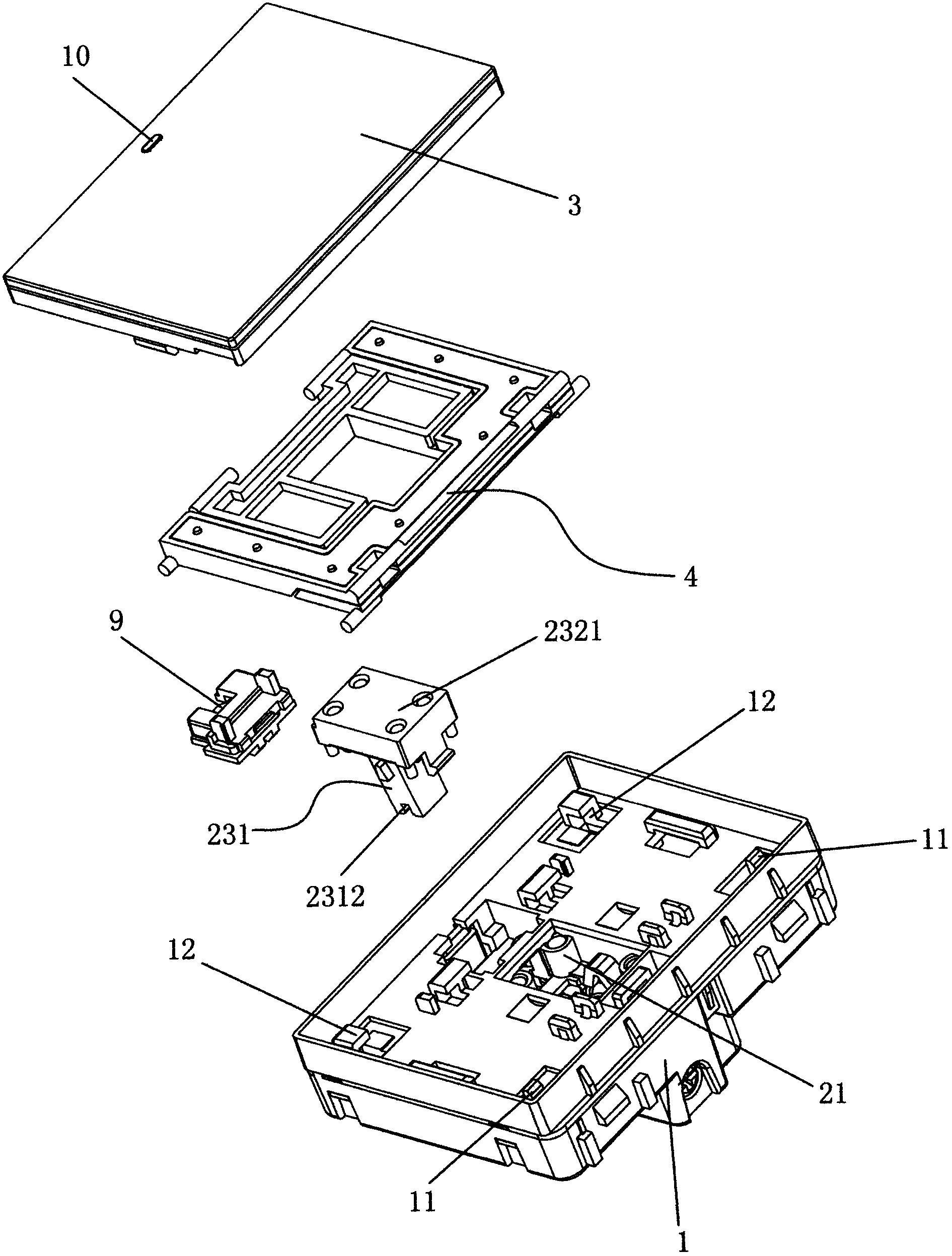

[0039] The switch function assembly 2 described in the present invention includes a conductive copper sheet group 21 arranged in the switch base 1, and a conductive paddle 22 that can change the opening and closing of the conductive copper sheet group 21 is provided in the switch base 1 , a switch drive mechanism 23 that can drive the conductive paddle 22 to rotate when pressed is provided in the switch base 1, and the switch drive mechanism 23 extends out of the installation hole 425 and abuts against the flat switch button 3 on the underside. The switch driving mechanism 23 described in this embodiment includes a rocker arm 231 that is clamped on the conductive plectrum 22. The rocker arm 231 includes a rocker arm seat 2311, and the rocker arm seat 2311 One end is provided with a clamping groove 2312, and a limiting clamping groove 221 is provided on the conductive plectrum 22, and a limiting protrusion is arranged in the limiting clamping groove 221, and the rocker arm seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com