Device for preventing hot air from being reflowed in waterproof cover of aerator and waterwheel-type aerator

A technology of water wheel aerator and hot air return, applied in water/sludge/sewage treatment, water aeration, sustainable biological treatment, etc., can solve the problem that the motor cannot work at full load, the bearing is easily damaged, and the The effect of motor cooling and other issues, to achieve the effect of temperature rise reduction, increase load, and injection molding cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

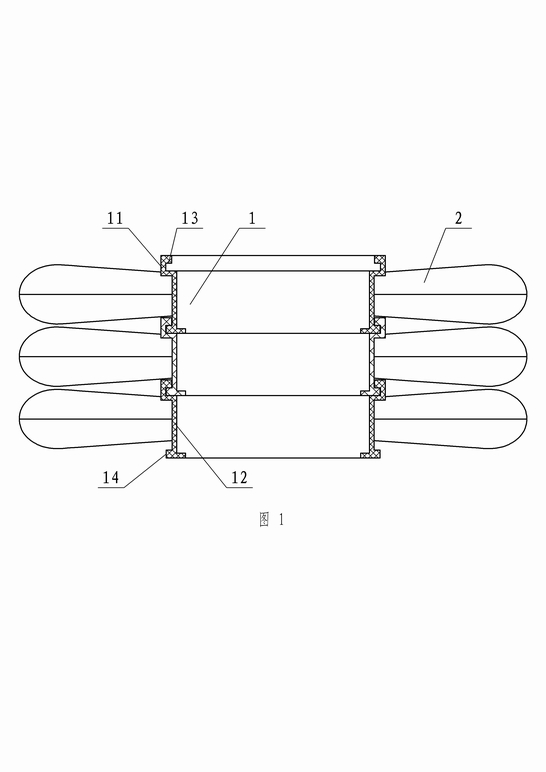

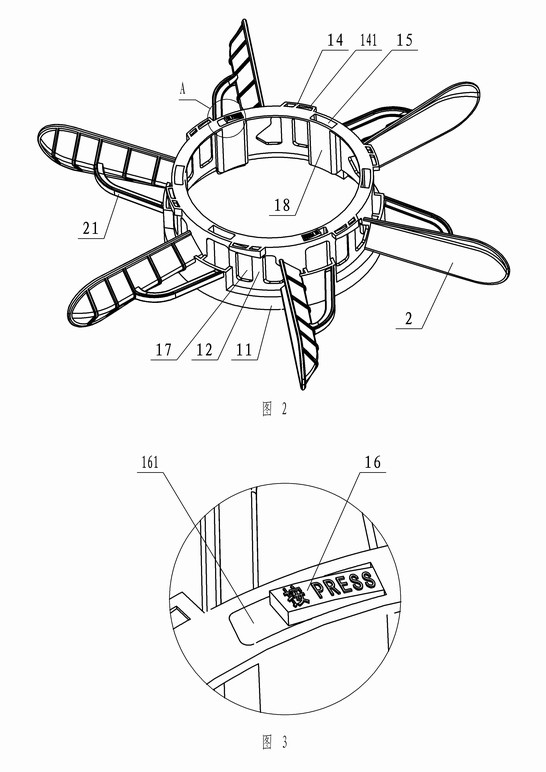

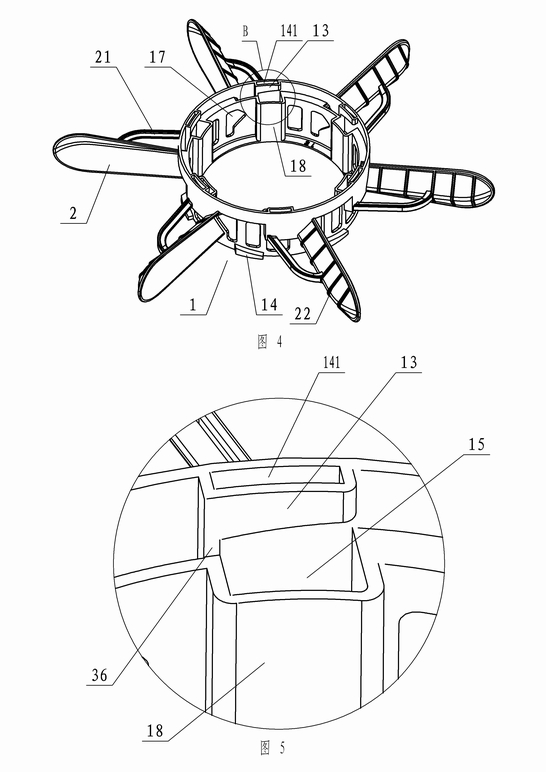

[0048] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-26 :

[0049]The device for preventing the backflow of hot air in the waterproof cover of the aerator of the present invention includes a motor 82 and a waterproof cover 96, and is characterized in that the motor 82 is installed vertically, the upper end of the motor has a cooling fan 95, and the cooling fan has a fan cover 9 outside the motor. There are a plurality of cooling fins on the shell, and a waterproof cover 96 is arranged outside. There is an air inlet on the waterproof cover and an air outlet below. There is an isolation device between the waterproof cover 96 and the motor to prevent the hot air of the motor from flowing back upwards into the fan cover of the motor, so that the cooling The hot air formed after the heat exchange between the wind and the cooling fins no longer flows back into the motor fan cover 9, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com