Pipe bender and bending method using pipe bender

A pipe bending machine and pipe bending technology, which is applied in the field of bending, can solve problems such as bending pipes, and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

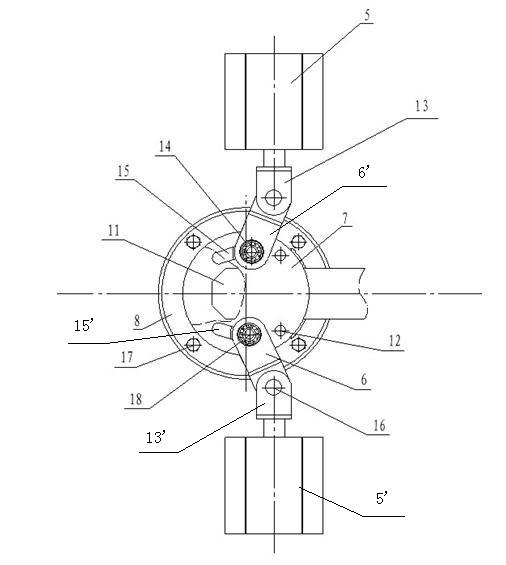

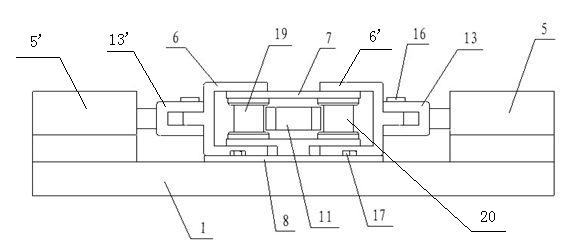

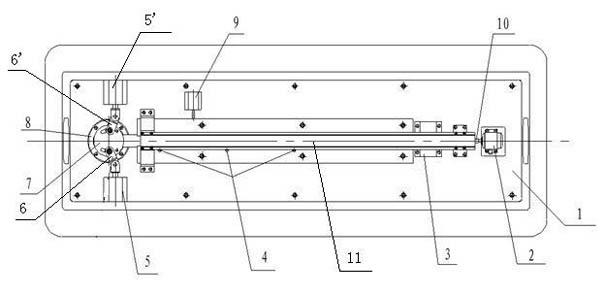

[0031] Embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0032] An embodiment of a pipe bender, such as Figure 1~3 As shown, it includes a workbench 1, a feed mechanism set on the workbench 1, a compression mechanism for pressing pipes, and a pipe bending mechanism for bending pipes. The feed mechanism includes a motor 2, a coupling 10. The lead screw 21 connected to the shaft coupling 10 and the nut seat push frame 22 driven by the lead screw 21. The nut seat push frame 22 includes a nut seat 35 and a nut 36 fixedly connected to the nut seat 35. The lead screw 21 slides Perforated in the hole 37 of the nut seat, the pipe bending mechanism includes a mandrel 11 arranged on the workbench and a first roller 19 and a second roller 20 vertically arranged on the workbench, the workbench includes a table top and The mandrel heads of the two rollers 19, 20 and mandrels are all arranged on the chassis 8, and the outer periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com