Rotating-tower-type automatic tool changer of numerical control machine tool

A technology of automatic tool change and CNC machine tools, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of difficult installation and maintenance, low work efficiency, and short service life, so as to improve reliability, The effect of reducing tool change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples.

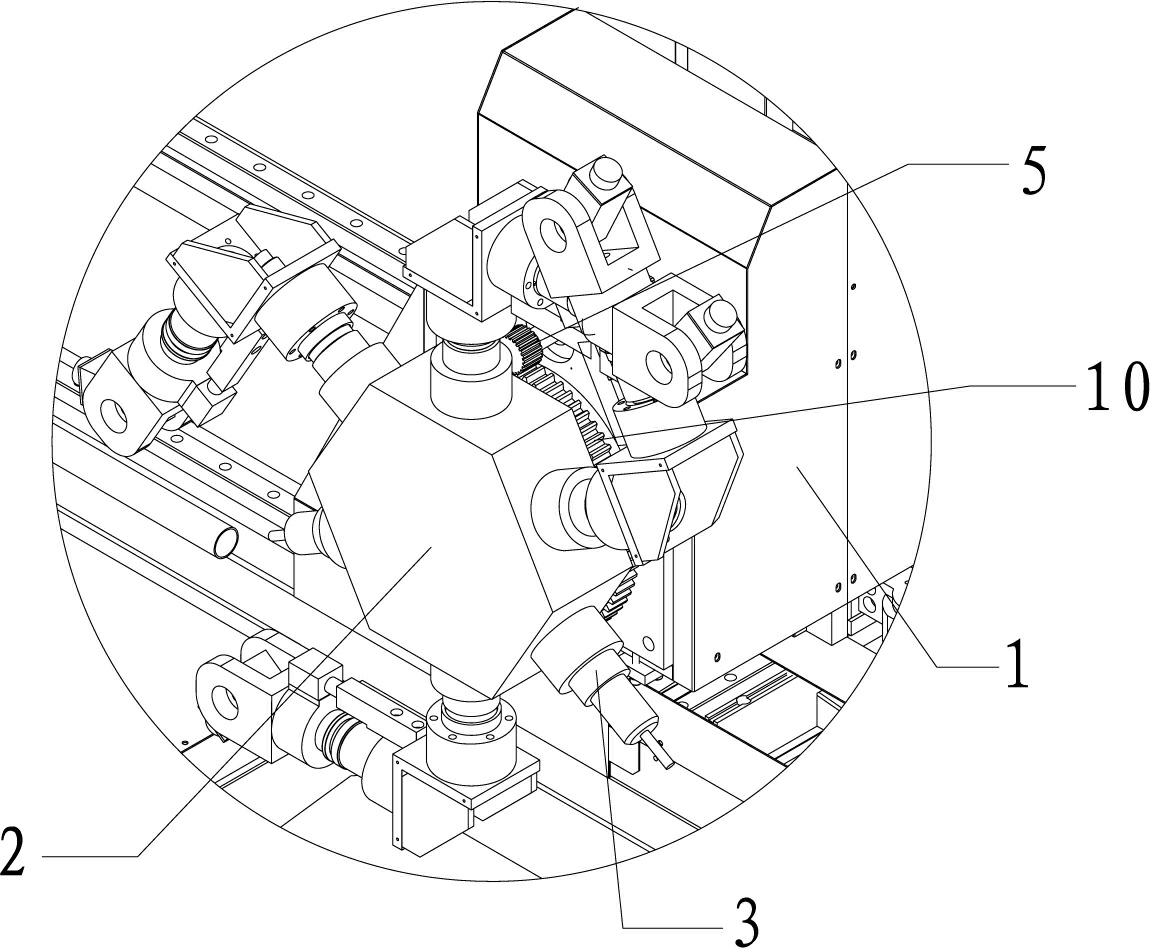

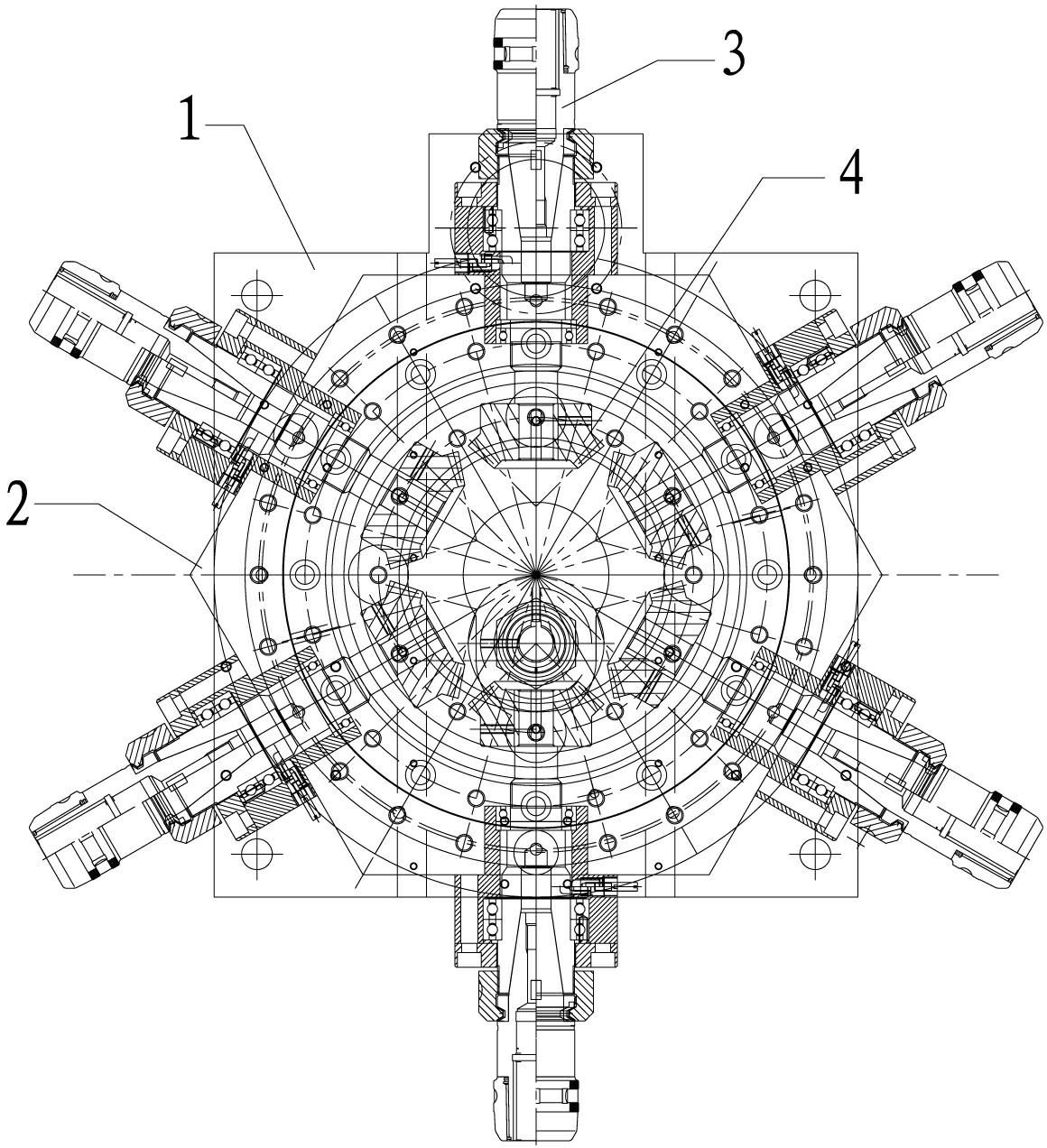

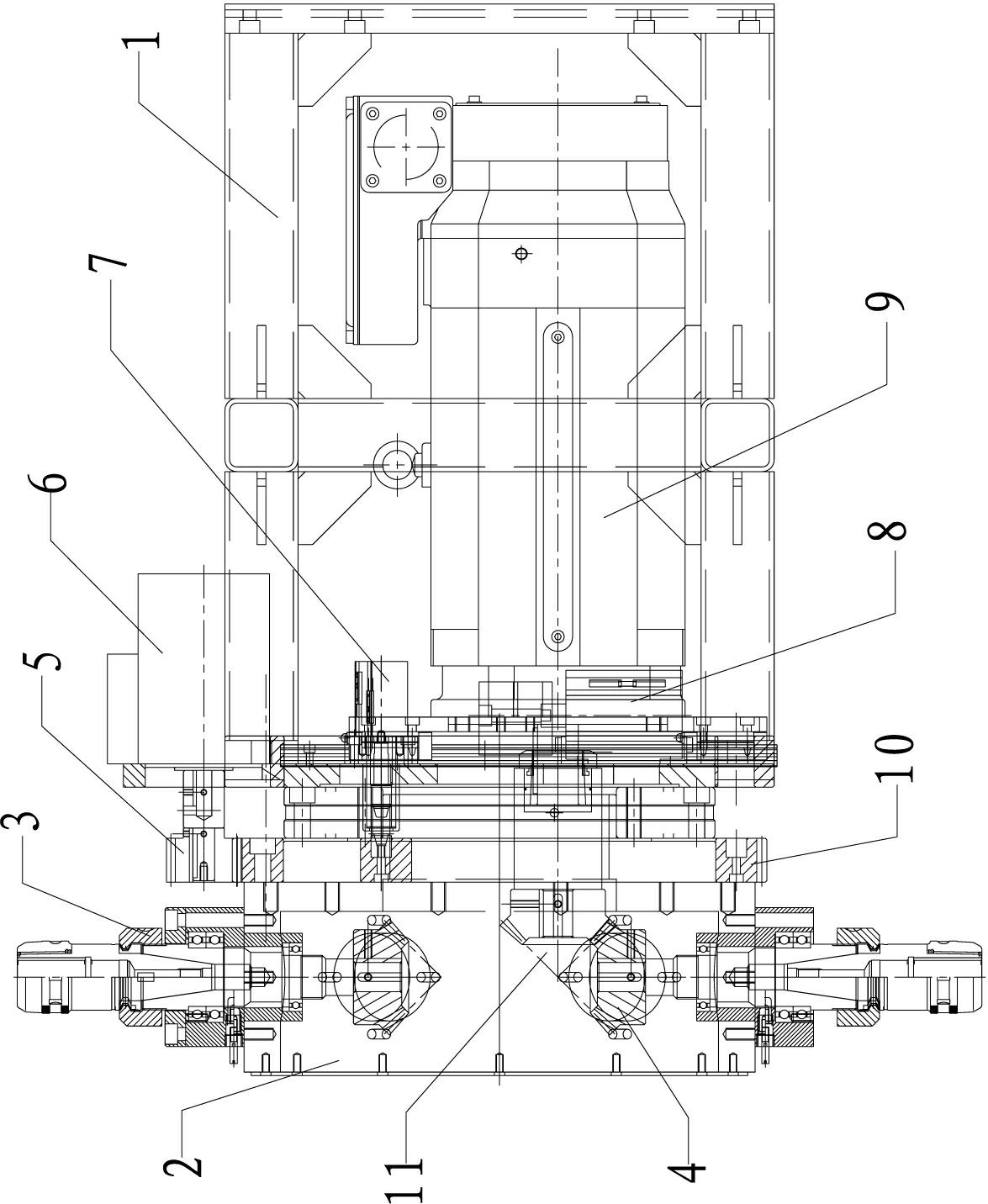

[0012] See attached figure 1 to attach image 3 As shown, the turret-type automatic tool changer of the CNC machine tool described in this embodiment includes a tool holder 1, a turret head 2, a spindle head 3, a spindle bevel gear 4, a tool changer gear 5, a tool changer motor 6, Positioning cylinder 7, lifting cylinder 8, spindle motor 9, wherein, the turret head 2 described in the present embodiment is a hexagonal turret head, which is rotatably assembled on the turret head mounting position at one end of the tool rest 1, and the tool change motor 6 is horizontally installed on the top of the tool rest 1, and a tool change gear 5 is mounted on the rotating shaft head of the tool change motor 6, and at the same time, one end of the turret head 2 connected with the tool rest 1 is correspondingly installed with the above-mentioned change gear. The gear plate 10 meshed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com