Material-charging material-taking servo simulated manipulator

A technology of manipulators and manipulators, applied in the field of manipulators, can solve the problems of installation, maintenance and control difficulties, no self-locking function, high production cost, etc., and achieve the effect of flexible and light work, convenient operation and use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

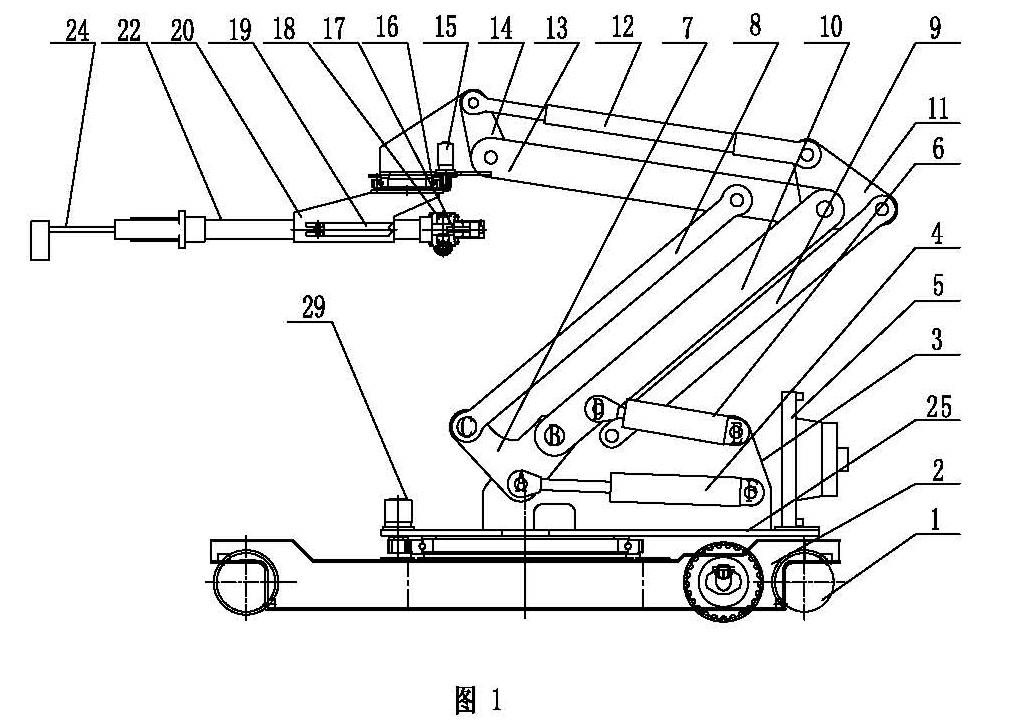

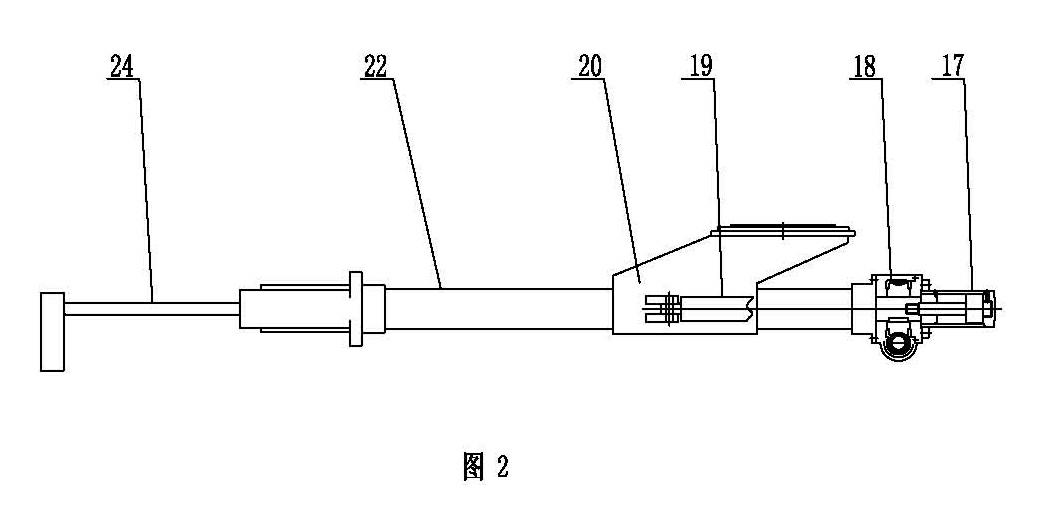

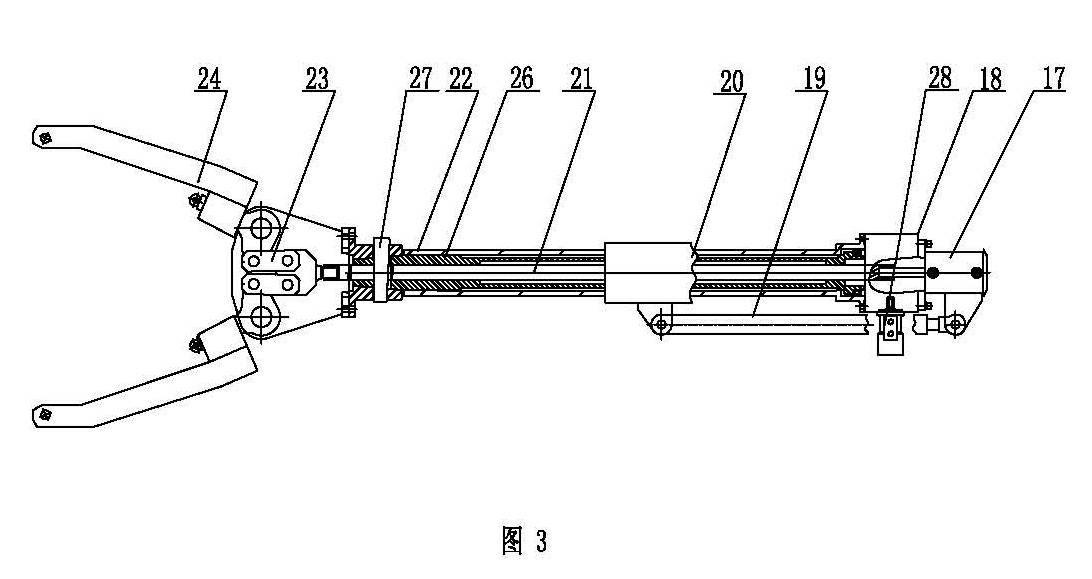

[0019] What is shown in the figure is an embodiment of a loading and unloading servo simulation manipulator for a large workpiece used for metal heat treatment. The bottom surface of car body 2 among the figure is installed double rim flat tread wheel 1, and wheel 1 both sides have flange, and the circumferential surface of wheel 1 cooperates with the guide rail that is fixed on the foundation. The car body hydraulic power of this embodiment is the car body hydraulic motor, the car body hydraulic motor is installed on the car body 2, the car body hydraulic motor output shaft is connected to the pin gear, and the pin gear meshes with the pin rack fixed on the foundation, as shown in Fig. The pin rack is not shown in . The wheel set including the wheel 1, the wheel shaft and the wheel frame is detachably fixed on the bottom frame of the vehicle body 2 by bolts, and the wheel 1 is a driven wheel. The car body hydraulic motor drives the car body 2 to walk left and right. The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com