Automatic special-shaped handle mechanism

A handle and special-shaped technology, which is applied in the field of automatic special-shaped handle mechanism, can solve the problems of poor strength, high cost, and high labor intensity of oil bottles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

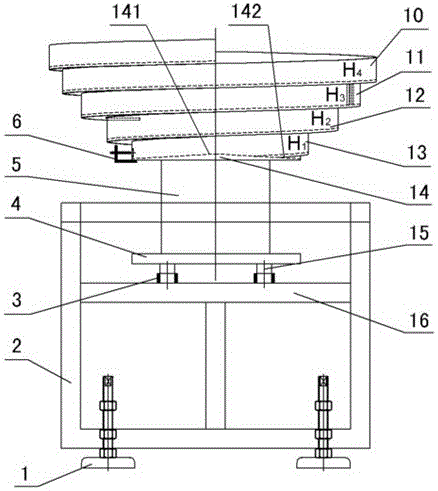

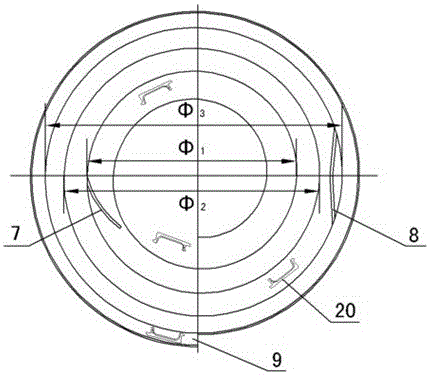

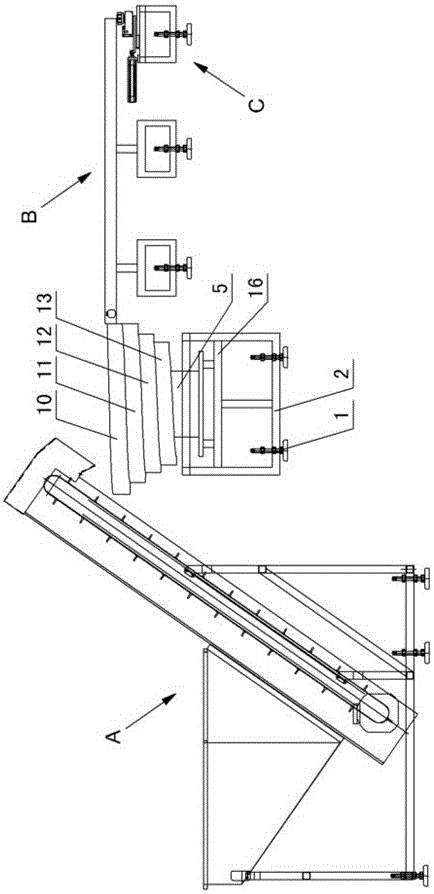

[0010] The invention relates to a mechanism for automatically sorting special-shaped handles, such as figure 1 — image 3 As shown, it includes a main power source, a bucket bottom plate, a fixed seat, a track, a detection switch, a swing needle, an adjustment plate and a bracket, the main power source 5 is arranged on the bracket 2, and the bucket bottom plate 14 is set on the main power source 5, the bucket bottom plate 14 is welded together with the rails 10, 11, 12, 13, and there is a swing needle 7 on the rail, which swings under the vibration of the active power source, and there is also an adjustment plate on the rail 8. The handle slides upward along the track under the vibration of the active power source. At the same time, under the action of the swing needle 7 and the adjustment plate 8, the handle slides out of the discharge port 9 regularly in a certain order. It is characterized in that The bottom plate 14 of the bucket pan adopts a conical structure in which th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com