Vertical silicon carbide high-temperature oxidation device

A high-temperature oxidation and silicon carbide technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of inability to meet the requirements of SiC material oxidation process, and achieve easy temperature control, high heating rate, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

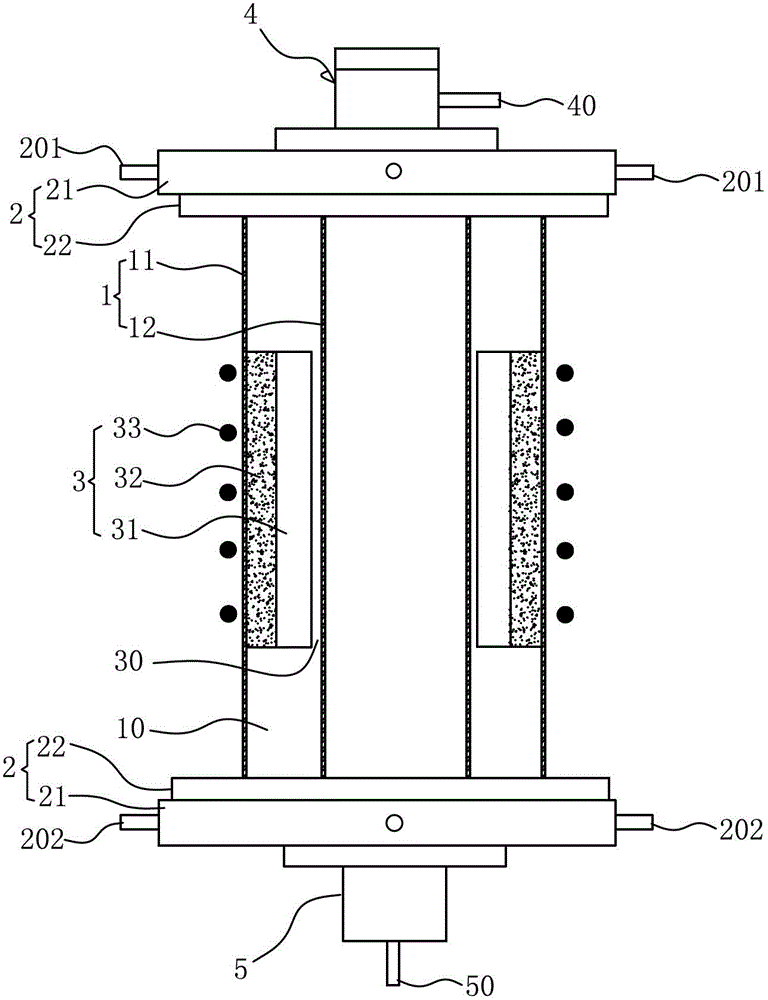

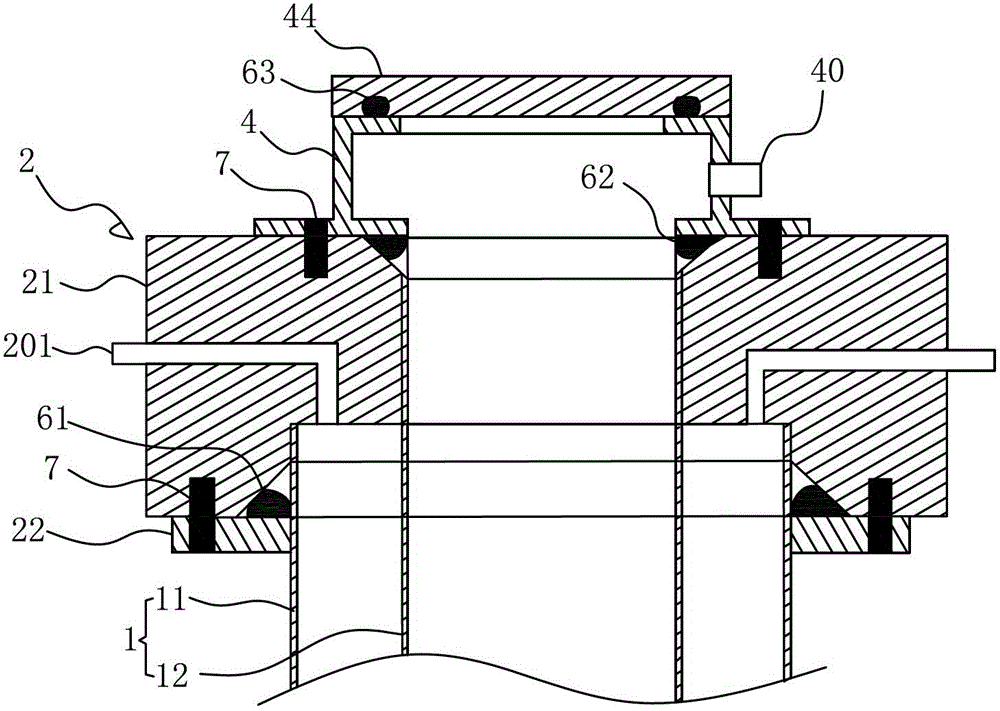

[0034] See figure 1 , 2 As shown, a vertical silicon carbide high-temperature oxidation device includes: a double-layer quartz tube nesting structure 1 , a sealing structure 2 , and a radio frequency heating component 3 . Wherein, the double-layer quartz tube nesting structure 1 includes: a vertically placed outer layer quartz tube 11 and an inner layer quartz tube 12 embedded in the outer layer quartz tube 11, the inner and outer layer quartz tubes 12, 11 to form an annular cavity 10 . Both ends of the double-layer quartz tube nesting structure 1 are respectively fixed and assembled through a sealing structure 2 to ensure that the inner and outer layers of quartz tubes 12 and 11 are isolated from each other. The inner cavity in the inner layer quartz tube 12 is used to place the products that need to be oxidized.

[0035] The radio frequency h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com