Construction method for ultrahigh combined support for bridge side span cast-in-situ section

A technology for combining brackets and bridges, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as low stability and failure to meet safety requirements, achieve high reuse rate, reduce material input and construction costs, The effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

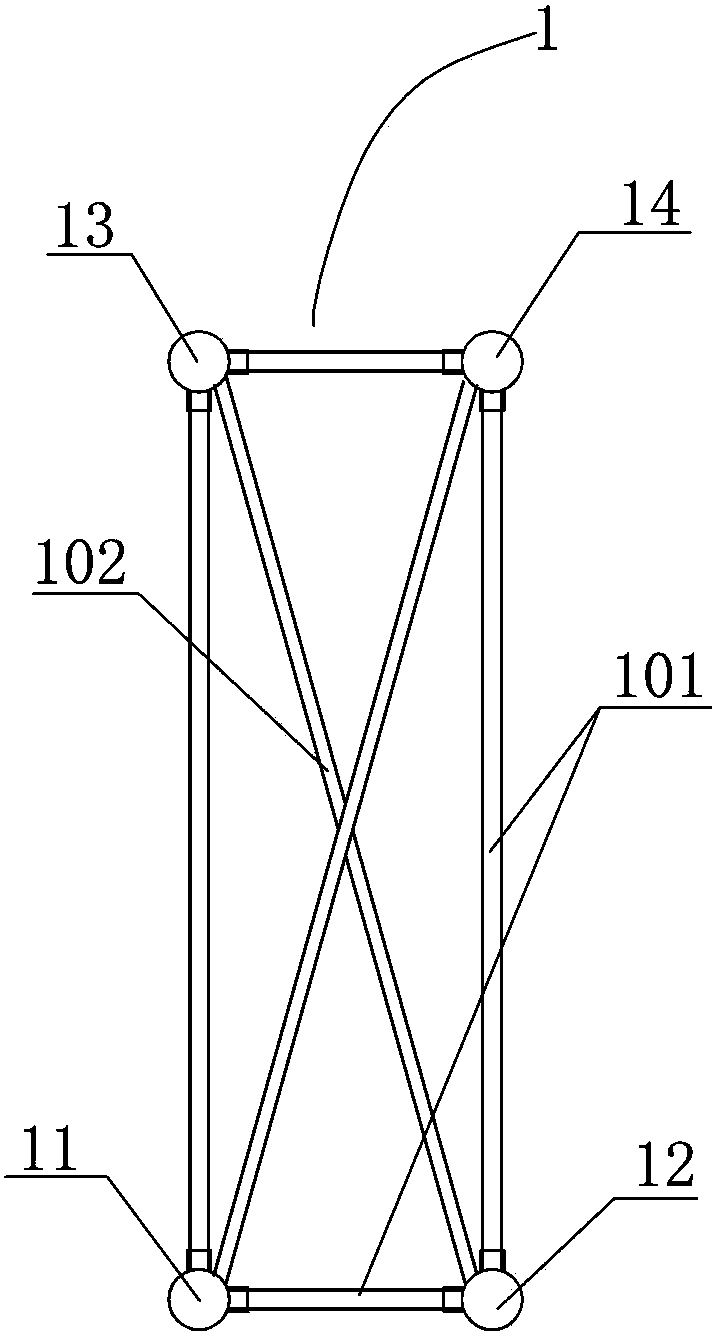

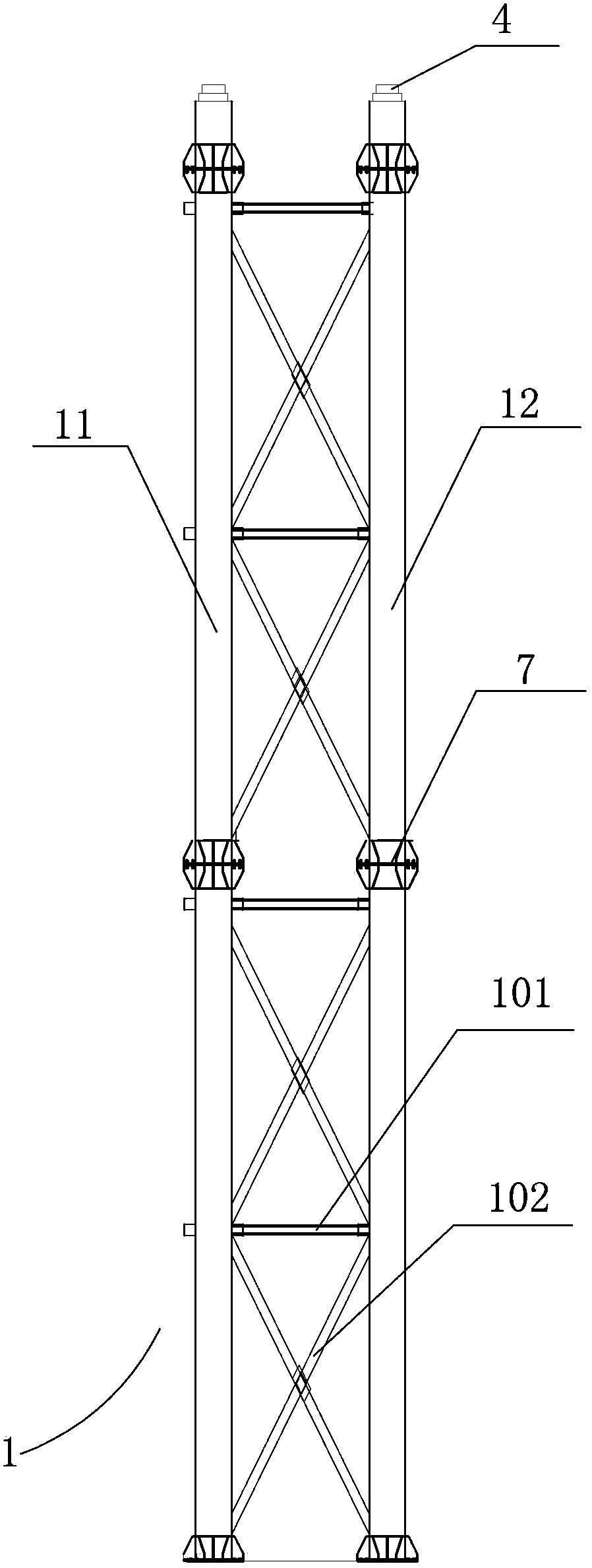

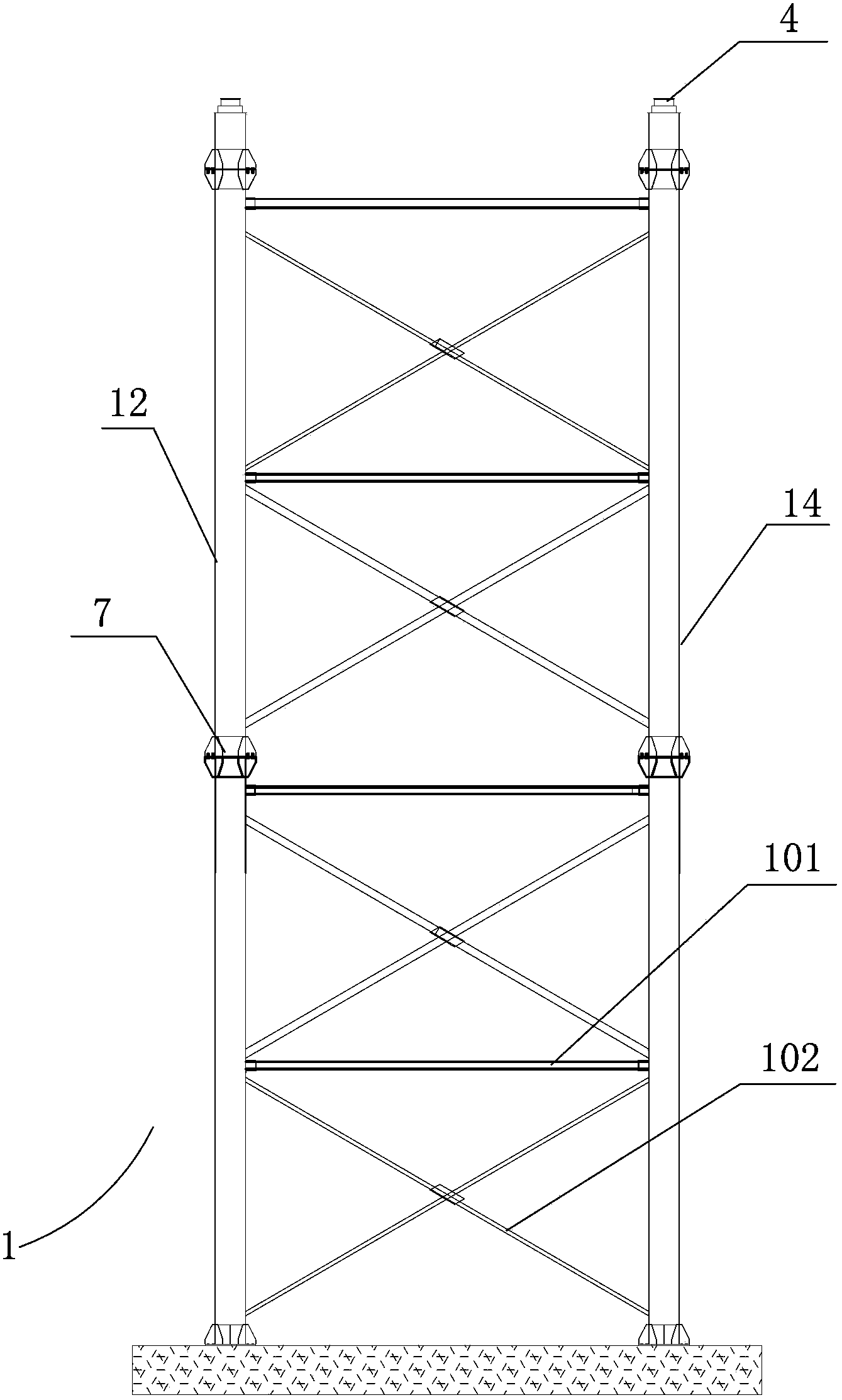

[0032] The present invention is a bridge side-span cast-in-place section ultra-high composite support, comprising a beam-column support 1, and two cantilever brackets 3 fixed on the bridge transition pier body 2;

[0033] Such as figure 1 , figure 2 , image 3 As shown, the beam-column support 1 includes four columns of the same height located at the four vertices of a rectangle in the horizontal direction, which are respectively the first column 11, the second column 12, the third column 13 and the fourth column 14 , each column is perpendicular to the ground and its lower end is fixed on the ground, usually on the expanded foundation of the bridge transition pier cap. The upper end of each column is fixedly provided with a column steel sand cylinder 4, and the steel sand cylinder is generally welded and fixed with the upper end of the column; between the first column 11 and the second column 12 and the third column 13, and between the fourth column 14 and the first column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com