Simple sliding grid anti-blocking gully

A kind of gully, simple technology, applied in waterway systems, water supply devices, drainage structures, etc., can solve the problems of small drainage capacity, affecting the sight of vehicles, reducing the strength of the road surface layer, etc., to restore the water intake capacity, reduce the ground Effects of standing water and expressway rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

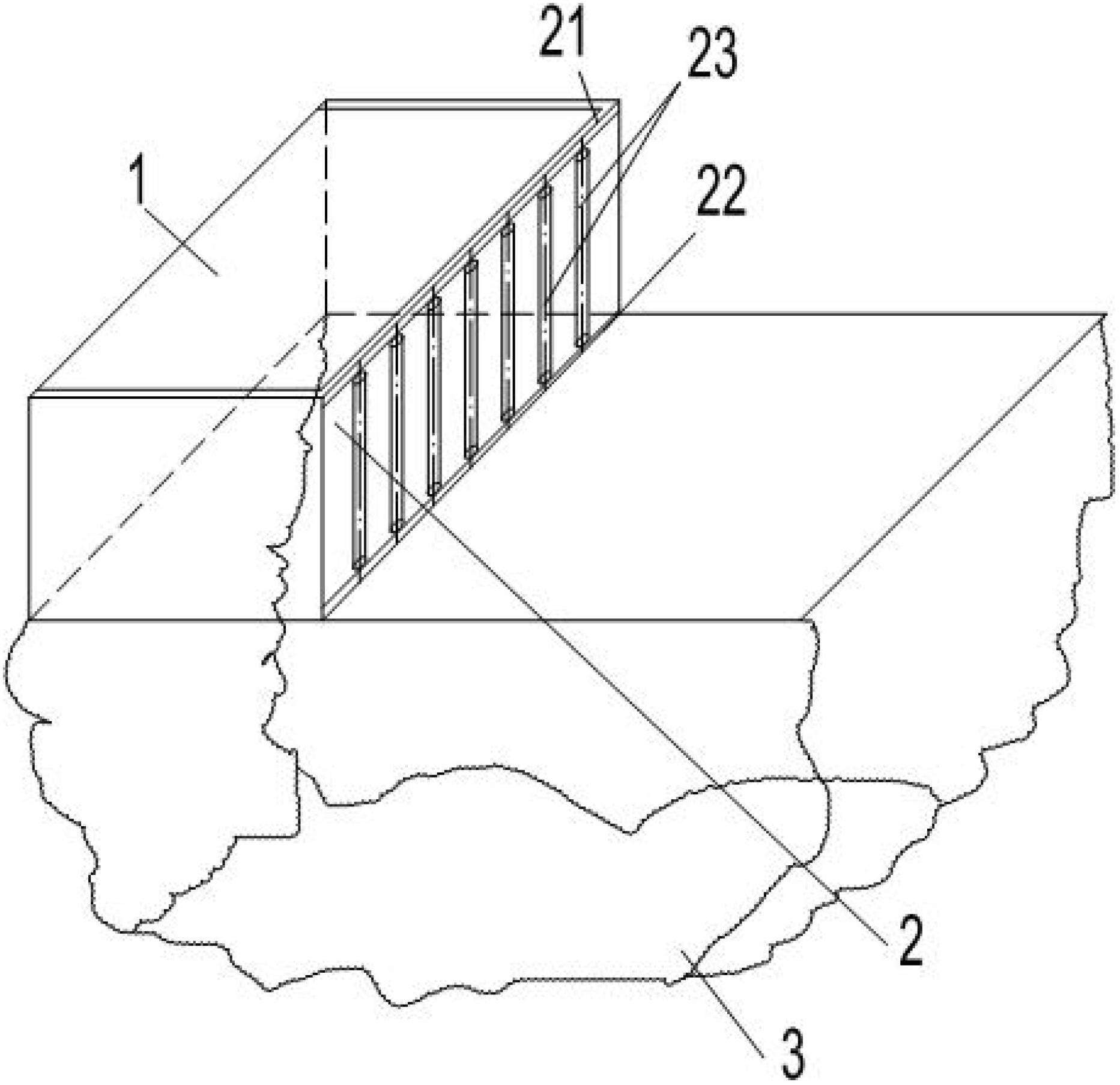

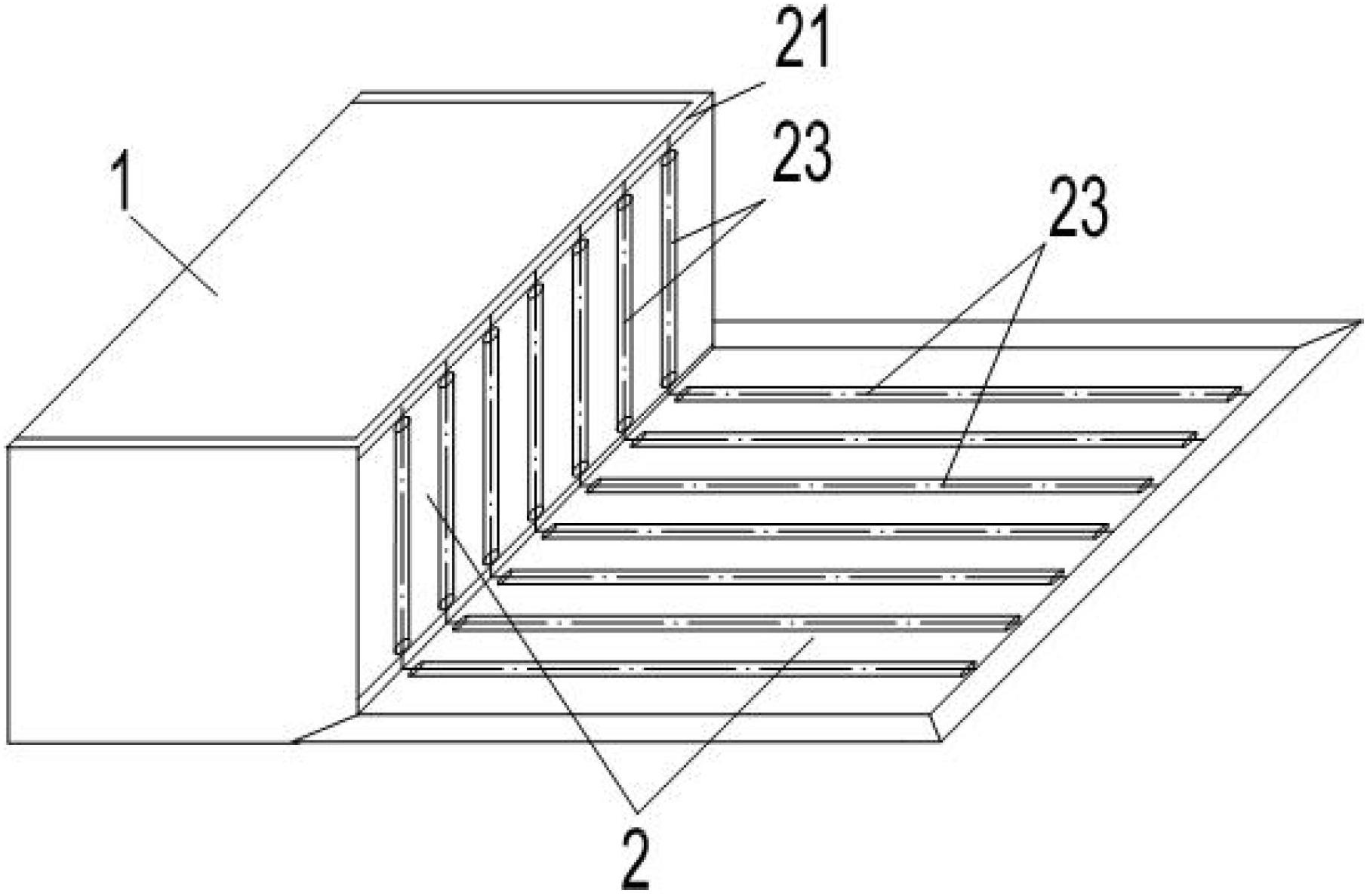

[0023] Such as figure 1 As shown, a specific embodiment of the simple sliding grid anti-blocking gully of the present invention mainly includes a gully body 1 and a gully cover 2 . The gully body 1 is a frame structure, and the part where the gully cover 2 is provided is an opening. The bottom of the gully body 1 is also provided with a dirt intercepting hanging basket 3 .

[0024] The upper part of the gully cover 2 is provided with an upper guide rail 21 , and the lower part is provided with a lower guide rail 22 . Both ends of the upper guide rail 21 are rotatably connected to the gully cover 2 through sliding steel balls (not shown in the figure). The lower guide rail 22 is separated from the gully body 1 .

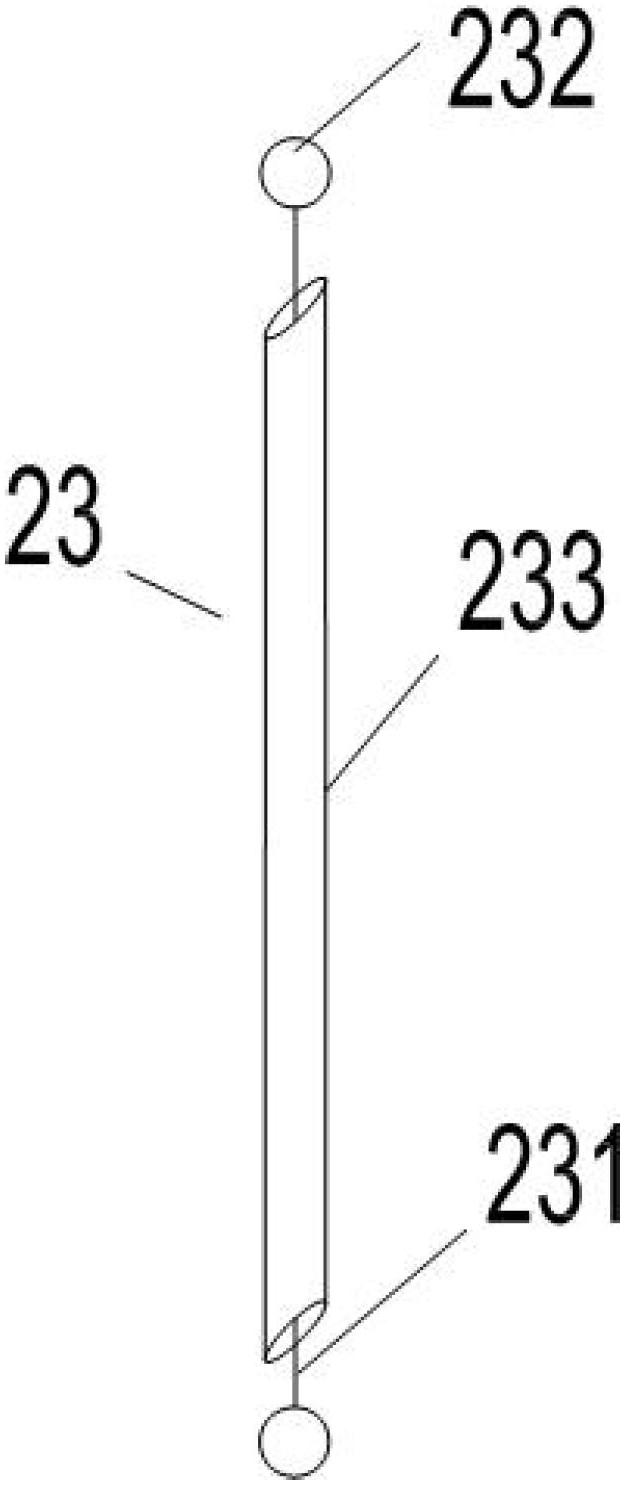

[0025] Several sliding grill bars 23 are slidably arranged between the upper guide rail 21 and the lower guide rail 22 . Such as figure 2 As shown, each sliding grating bar 23 includes a central rod 231 with steel balls 232 at both ends, and a hollow cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com