Dual-clutch transmission for hybrid power

A dual-clutch, hybrid technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high CVT cost, complex AT structure, long axial dimension, etc., to improve economic performance and internal structure Compact, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

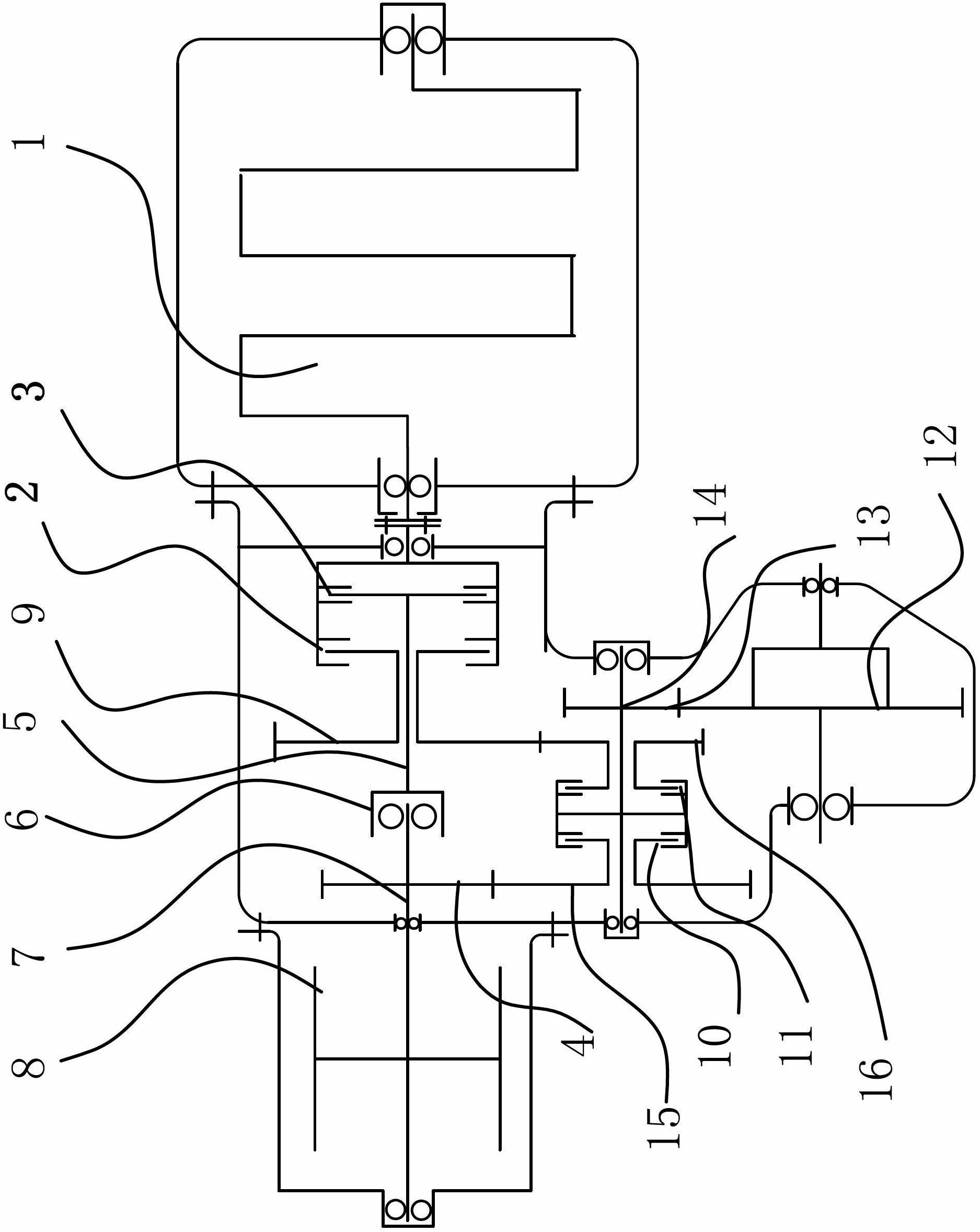

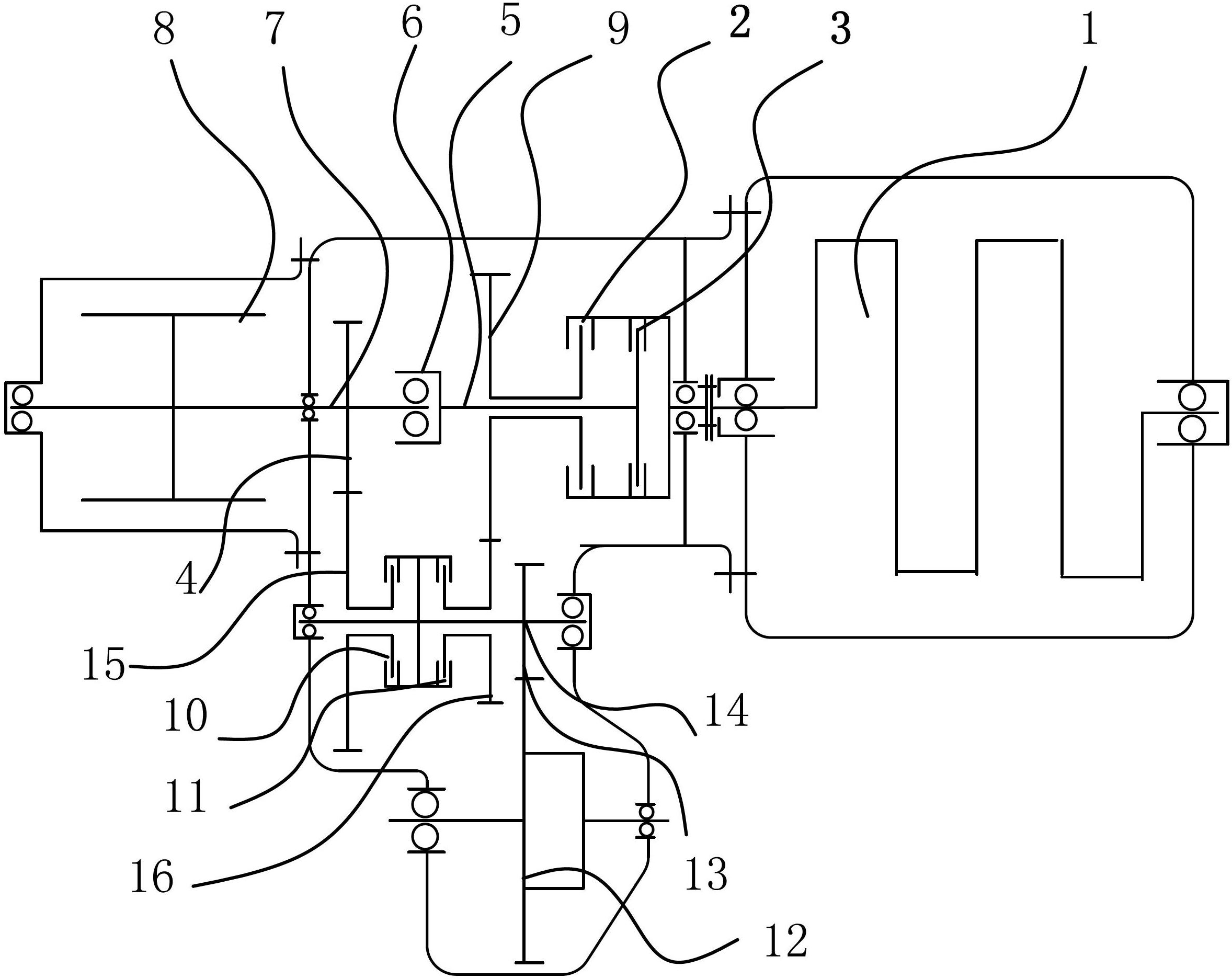

[0021] Such as figure 1 Shown, the dual-clutch transmission that this hybrid power is used comprises electric motor 8, engine 1, input shaft one 7, input shaft two 5 and output shaft 14, input shaft one 7 is connected with the output end of motor 8, input shaft two 5 and The output end of the engine 1 is connected, and the output end of the engine 1, the input shaft one 7, the input shaft two 5 and the output end of the motor 8 are coaxially arranged. Input shaft one 7 is fixedly provided with drive gear one 4, and input shaft two 5 is sleeved with drive gear two 9, input shaft one 7 and input shaft two 5 are connected by a one-way clutch 6, input shaft two 5 and engine 1 are connected through a double clutch one phase, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com