Helical gear and gap eliminating structure thereof

A helical gear and backlash elimination technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

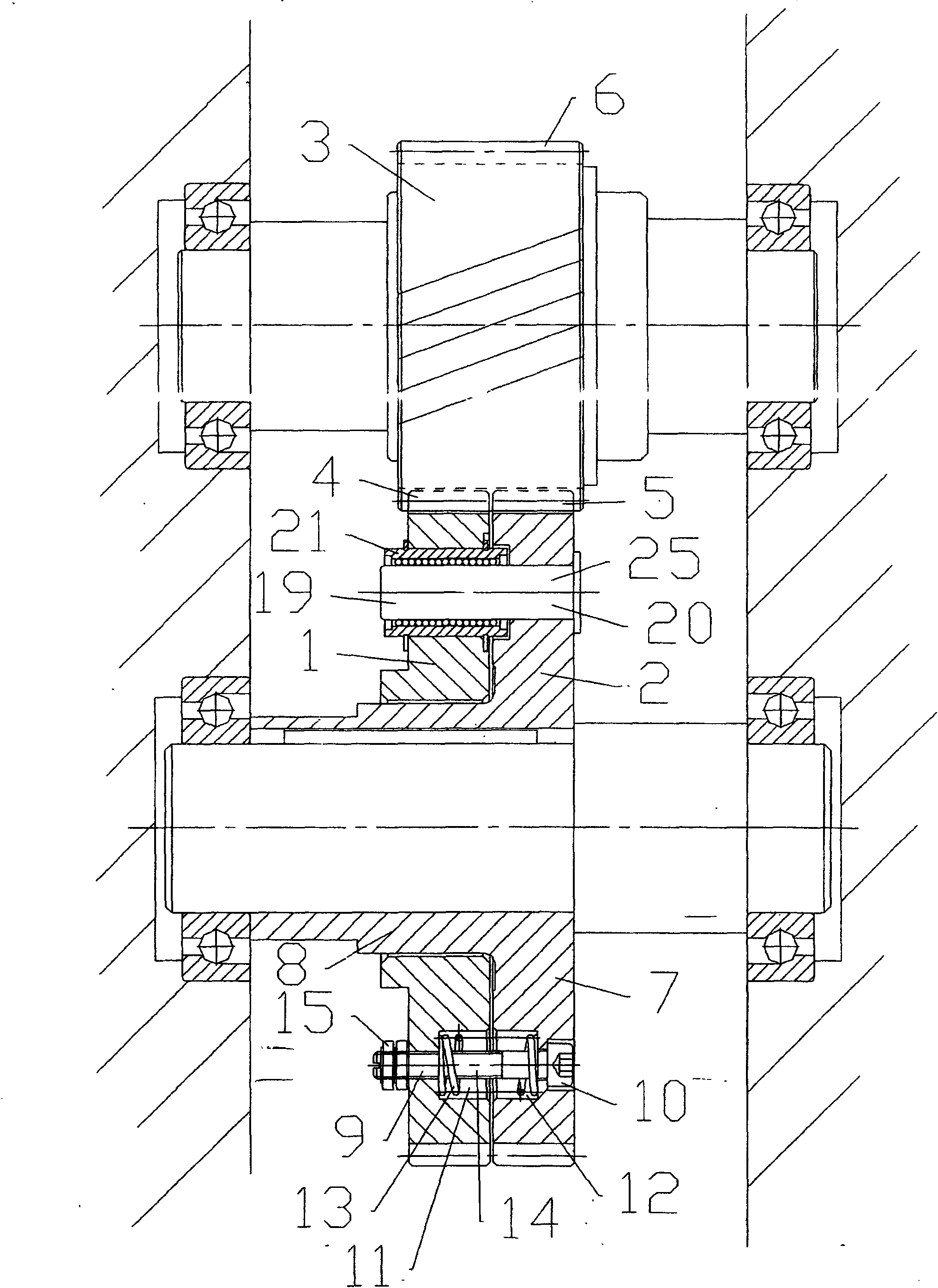

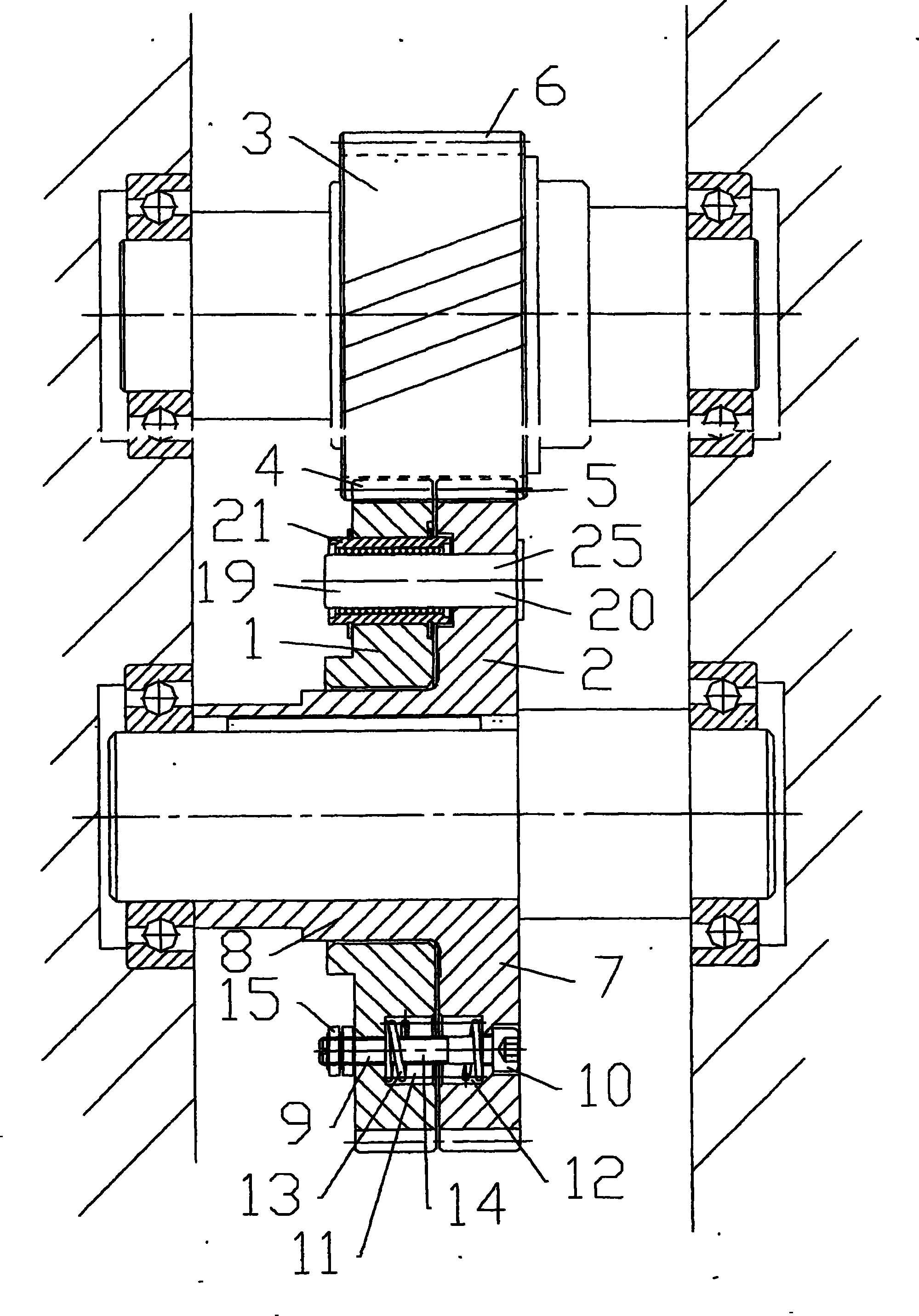

[0010] see figure 1 , a schematic diagram of the meshing of the helical gear 7 with the anti-backlash structure and the third helical gear 3 of other normal structures. The helical gear 7 includes a first part 1 and a second part 2 which are split along the cross section of the helical gear. The helical teeth on the first part 1 are first helical teeth 4 , and the helical teeth on the second part 2 are second helical teeth 5 . The second part 2 contains the hub 8 . Six counterbores 9 and 10 are evenly distributed on the first part 1 and the second part 2 along the circumferential direction of the helical gear 7 , and the counterbore part 11 of the counterbore 9 is opposite to the counterbore part 12 of the counterbore 10 . A helical cylindrical compression spring 13 is arranged in the opposite counterbore portions 11, 12, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com