Novel filtering brick

A filter brick, a new type of technology, applied in the direction of filtration separation, fixed filter element filter, sustainable biological treatment, etc., can solve the problem of unsuitable sewage treatment filter process, affecting the water distribution and gas distribution area of the filter tank, and having no air recoil function and other issues, to achieve the effect of simple installation, easy installation, and guaranteed success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

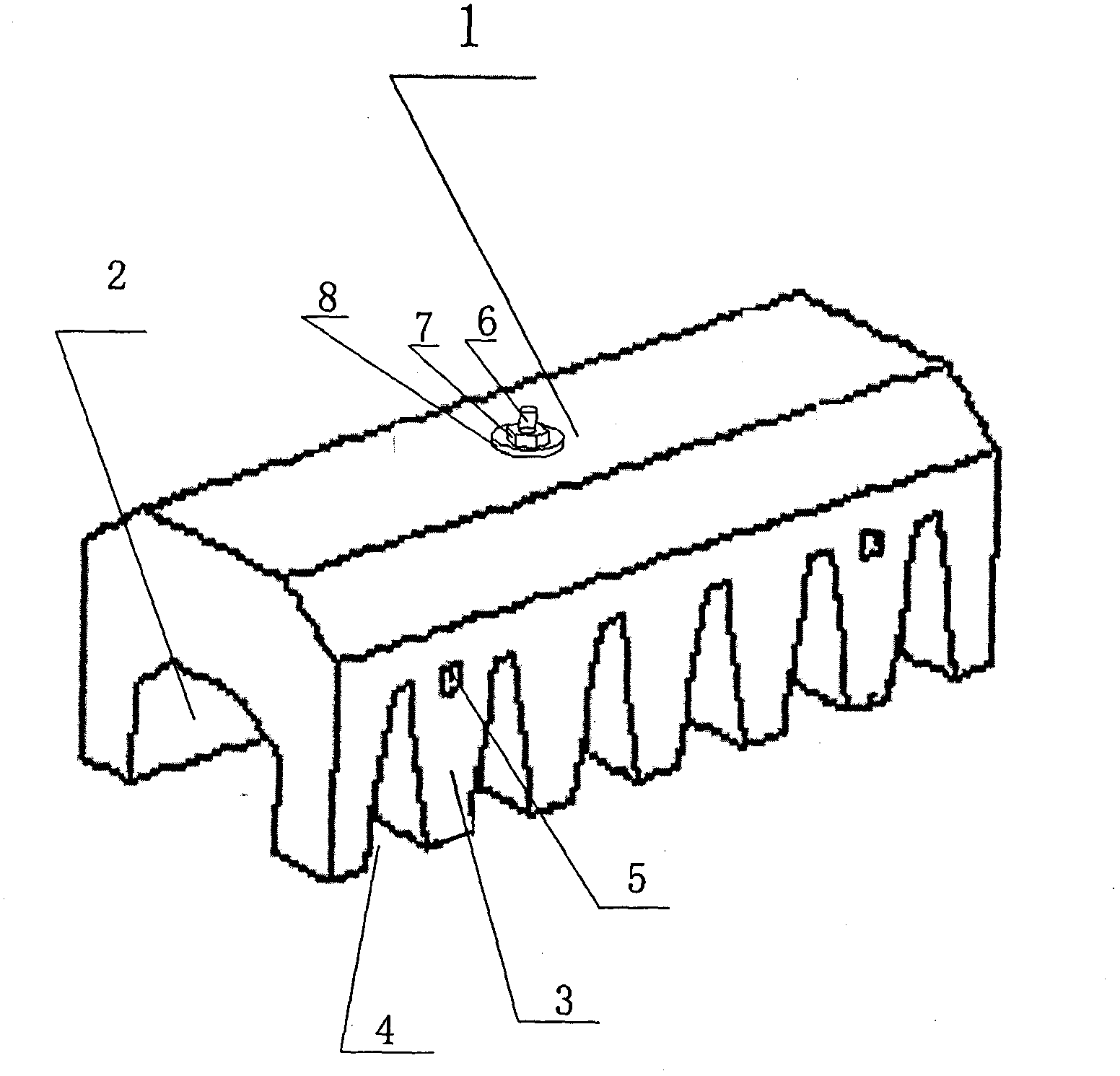

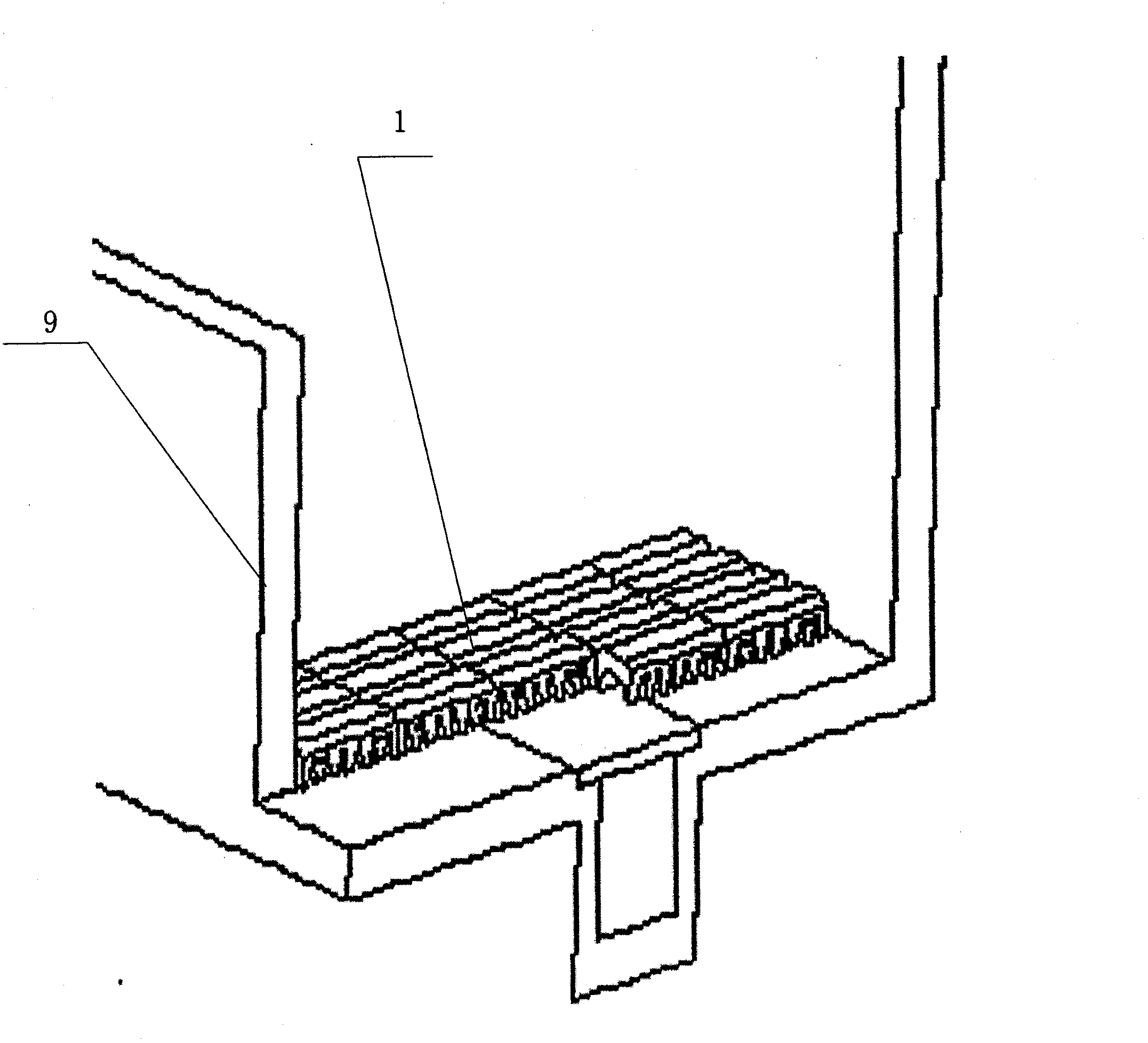

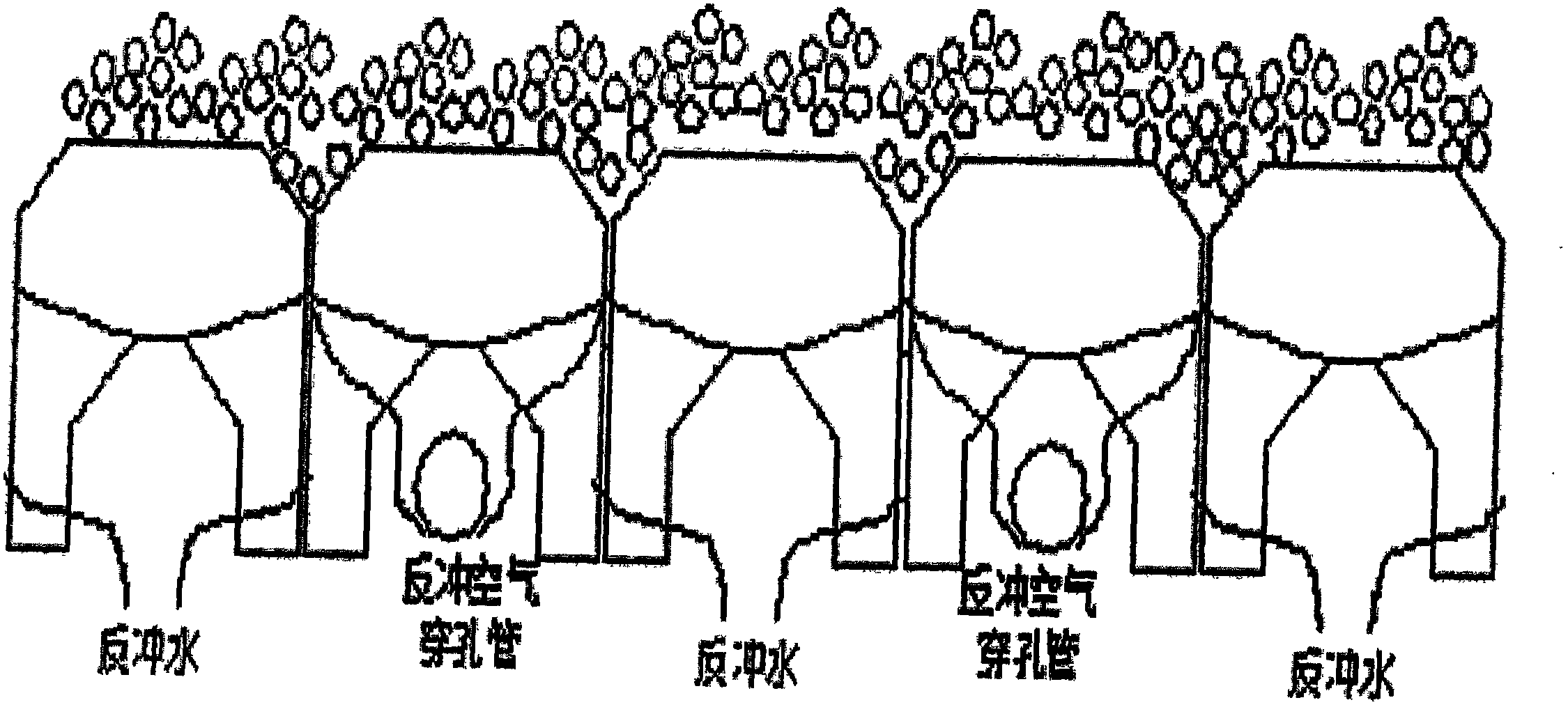

[0010] exist figure 1 Among them, the present invention provides a new type of filter brick, which includes a filter brick main body 1, the length of the filter brick main body 1 is 500-1100mm, and an inner cavity 2 is provided inside the filter brick main body 1, and the inner cavity 2 runs through from left to right The entire filter brick main body 1 is provided with a fixing device on the top of the filter brick main body 1. The fixing device includes a stainless steel anchor bolt 6, a gasket 7 and a nut 8. The bottom of the pool is fixedly connected, a gasket 7 is provided between the nut 8 and the top of the filter brick main body 1, the gasket 7 is set on the stainless steel anchor bolt 6, and several The brick foot 3 is provided with a gap 4 between the brick foot 3 and the brick foot 3, the gap 4 is set in a V shape, and a filter brick limit block 5 is arranged on the outer surface of the brick foot 3, and the filter brick limit block 5 is set as a concrete limit blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com