Dust discharging device of pulse bag type dust collector

A bag filter and pulse technology, applied in the field of pulse bag filter ash unloader, can solve the problems of inconvenience in repair and maintenance, drive chain and bearing repair and maintenance, blocking the ash discharge port, etc., to achieve easy maintenance and Maintenance, increased dust removal efficiency, and high ash discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

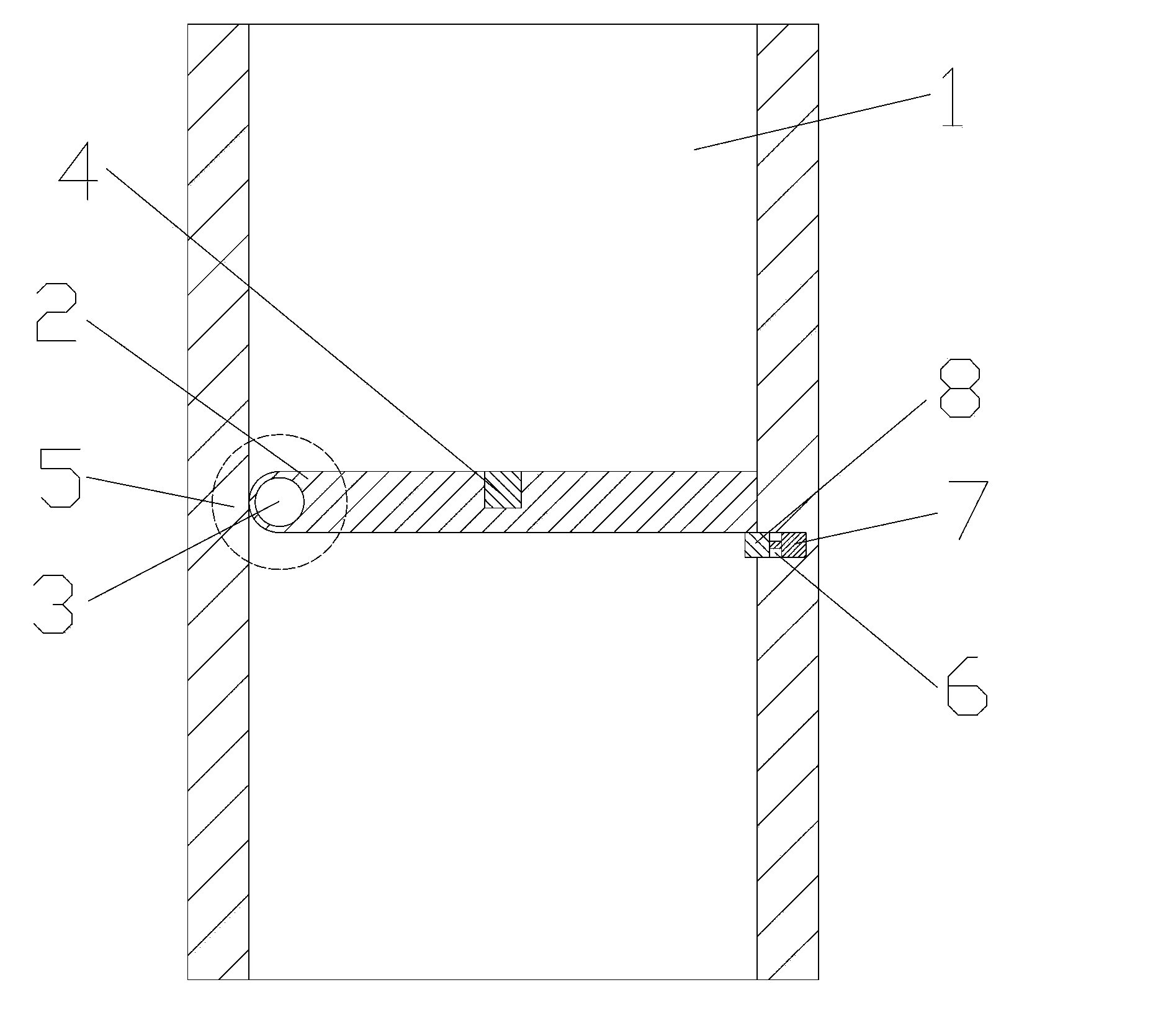

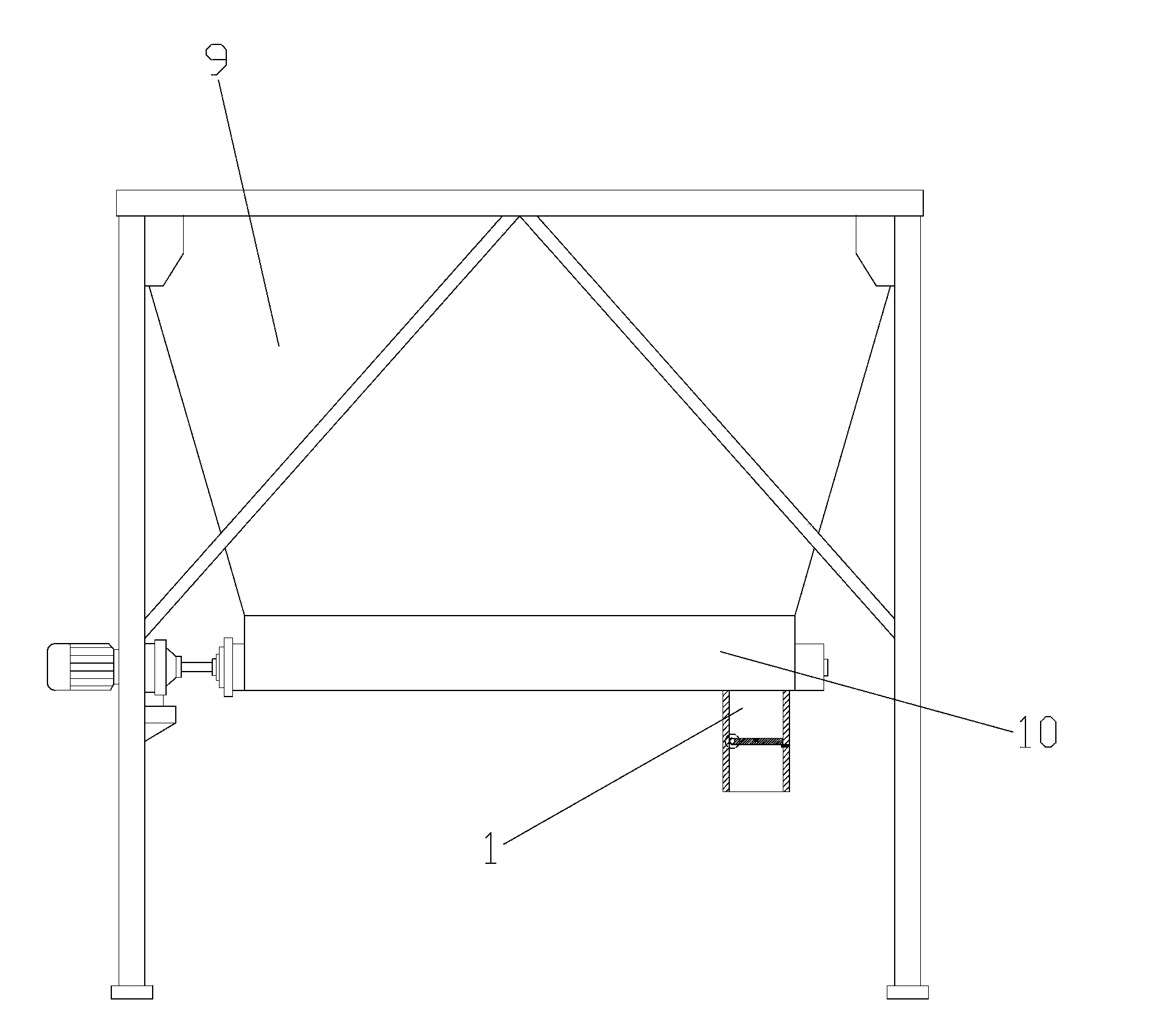

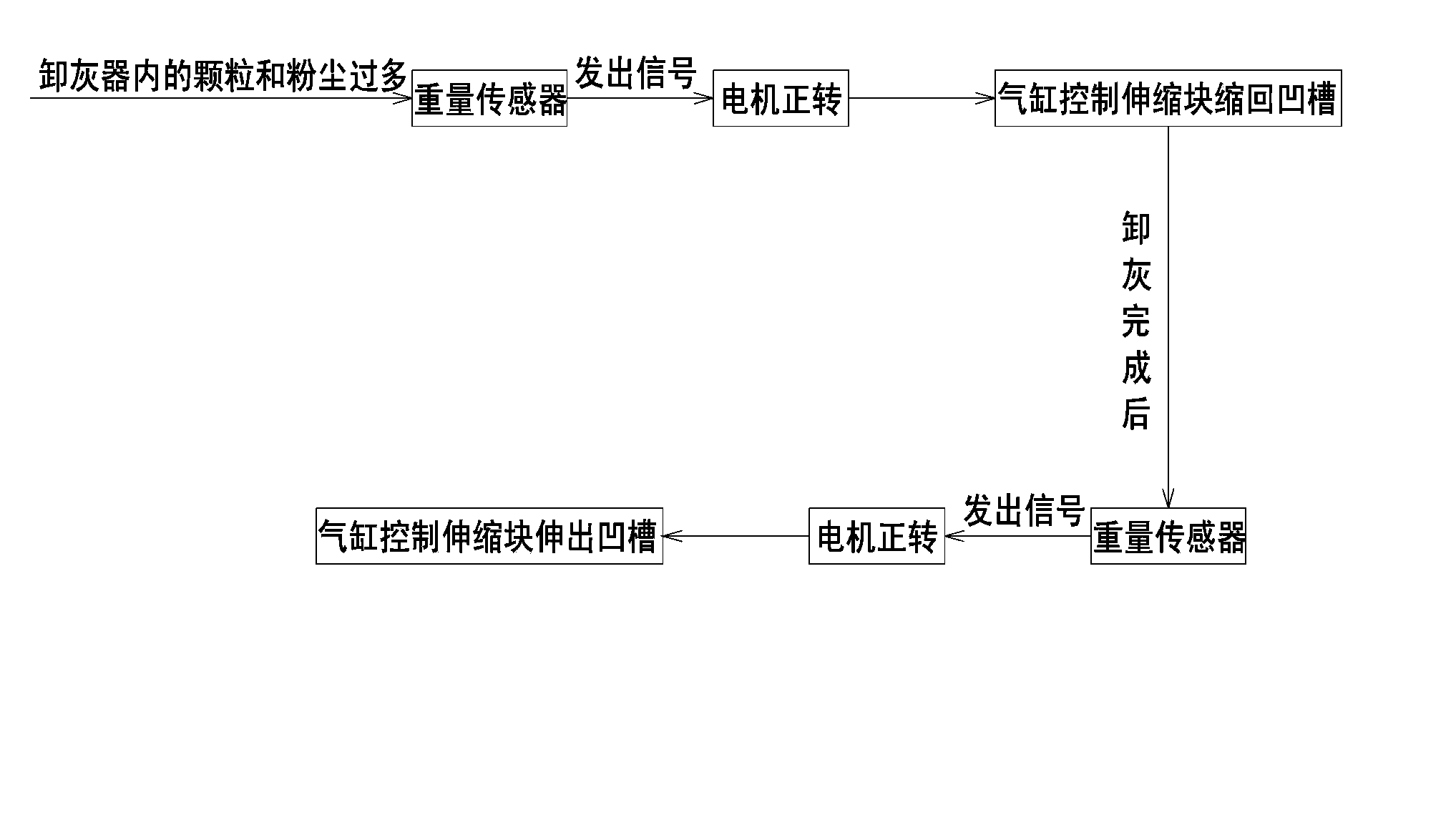

[0015] as attached figure 1 The shown ash unloader for a pulse bag filter according to the present invention includes an ash unloader body 1, and a flap device is provided inside the ash unloader body 1 to control the ash unloading of the ash unloader body 1. The flap device includes a flap 2, a rotating shaft 3, a weight sensor 4, a motor 5, a groove 6, a cylinder 7 and a telescopic block 8; The middle part; the inside size of the turning plate 2 is the same as that of the ash discharger body 1; a weight sensor 4 is provided inside the turning plate 2; the motor 5 is connected with the rotating shaft 3; the side wall of the ash unloader body 1 There is a groove 6; the upper surface of the groove 6 is flat with the lower surface of the flap 2 when it is in a horizontal position; the groove 6 is provided with a cylinder 7 and a telescopic block 8; the cylinder 7 controls the telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com