Drill hole combination fixture for vacuum roll

A technology of combining fixtures and vacuum rollers, used in clamping, manufacturing tools, supports, etc., can solve the problems of difficult processing and different sizes, and achieve the effects of fast operation, reduced investment cost, and guaranteed processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

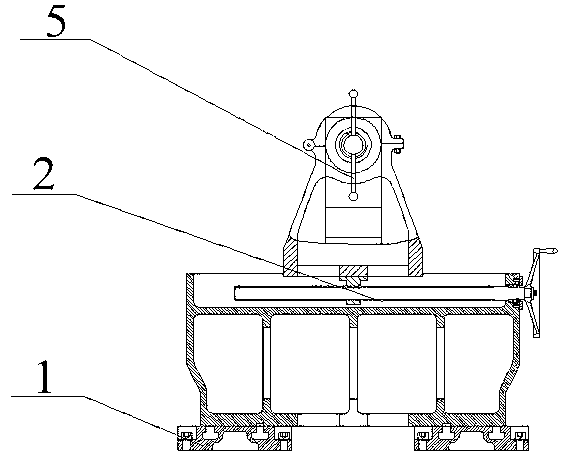

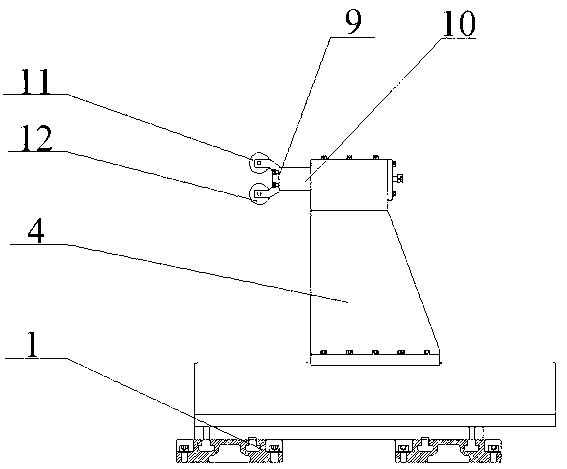

[0010] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a base 1, a first clamp device 2 and a second clamp device 3 are arranged in a line on the base 1, the positional relationship between the first clamp device 2 and the second clamp device 3 can be changed, and the first clamp device 2, An intermediate positioning clamp device 4 is also provided between the second clamp device 3, and the first clamp device 2 includes a handle 5 and a thimble 6, and the handle 5 is fixed on the end of the thimble 6; the second clamp device 3 includes a four-jaw chuck 7, a rotating The shaft 8 and the four-jaw chuck 7 are fixedly connected to the end of the rotating shaft 8; the intermediate positioning fixture device 4 includes a roller, a roller frame 9, and a piston 10, and the rollers include an upper roller 11, a lower roller 12, an upper roller 11, and a lower roller 12 It is symmetrically fixed on the end of the roller frame 9, and the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com