Automatic loading and unloading device

An automatic loading and unloading technology, which is applied in positioning devices, clamping, and supports, can solve the problems of heavy repetitive work, low automation level, and low production efficiency for workers, and achieve improved production efficiency and economic benefits. The effect of saving labor and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment and accompanying drawing thereof, the present invention is described in further detail:

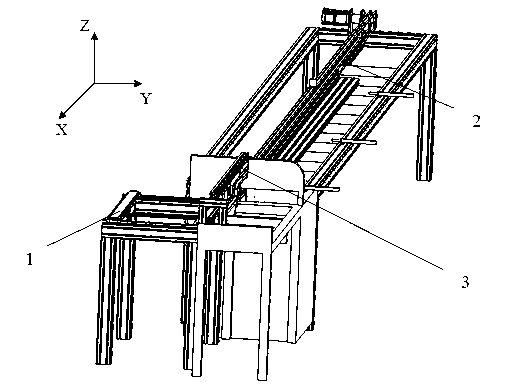

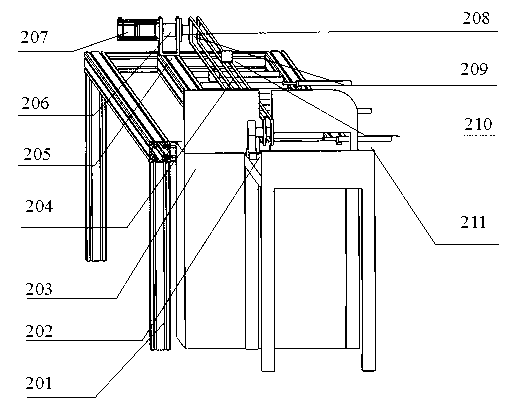

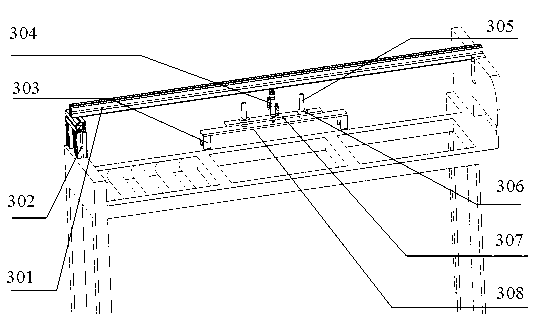

[0013] The automatic loading and unloading device designed by the present invention (abbreviation device, see figure 1 -4) is based on the automatic processing technology requirements for the cutting of aluminum frame blanks of solar panel components (abbreviated as blanks), follows the design idea of modular robot structure, and is designed according to the cutting and processing process of aluminum frame blanks.

[0014] The automatic loading and unloading device designed by the present invention includes a mechanical structure part and a control system part. Among them, the mechanical structure part is composed of three modules, including the blank automatic loading module 1, the cutting blank clamping module 2 and the workpiece unloading module 3; the control system part is composed of the motion control system module. The various modules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com