Micro-nano active oxygen treatment method of sewage

A treatment method, micro-nano technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of the disappearance of self-purification ability of water areas, inability to directly oxidize and decompose, pollution, etc. problems, to achieve the effect of eliminating follow-up pollution and eliminating organic pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for treating sewage with micro-nano active oxygen, comprising the following steps:

[0034] a. Physicochemical: Sedimentation and desanding treatment of sewage;

[0035] b. Separation: The sewage is oxidized and separated by micro-nano bubbles, and the diameter of the bubbles is less than 50 microns;

[0036] c. Biological treatment: the sewage treated by micro-nano bubbles flows into the reaction tank with bionic biological carrier for nitrification and denitrification, anaerobic and aerobic reactions;

[0037] d. Discharge: After biological treatment, the COD removal rate of sewage reaches over 98% before discharge.

[0038] In the step a, a simple grid grit settling section is built, and the sewage is naturally collected through the grit settling section for natural sedimentation treatment.

[0039] In the step b, micro-nano bubbles are added to the overflow water of the sand settling section to carry out oxidation and separation reaction.

[0040] In the...

Embodiment 2

[0048] The present invention is described in detail below:

[0049] The process flow is: Sewage -----> Simple grid grit settling -----> High-energy oxidation separation of micro-nano bubbles -----> Bionic biological carrier purification advanced treatment -----> Discharge or reuse .

[0050] The physical and chemical step is to select the natural terrain (or use ditches) to build a simple grid grit settling section, and the sewage is naturally collected through the grit settling section for natural sedimentation treatment.

[0051] The process flow of high-energy oxidation separation of micro-nano bubbles is: overflow water in the sand setting section-high-energy oxidation separation reaction of micro-nano bubbles

[0052] The technological process of the biological step is: biomimetic biological carrier + micro-nano bubble treatment - discharge or agricultural irrigation reuse.

[0053] The principle of micro-nano bubble purification sewage:

[0054] The micro-nano-bubble ...

Embodiment 3

[0060] The present embodiment describes in detail the multi-magnetic field whirling micro-fine oxygen bubble generator used in the present invention, but is not limited to this generator, as long as the diameter of more than 95% of the bubbles in the input bubbles is less than 50 microns, the minimum diameter can reach 10 microns. Nano or so will do.

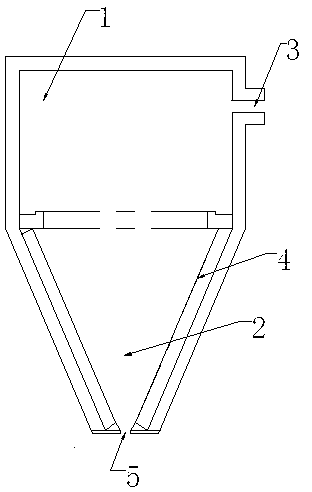

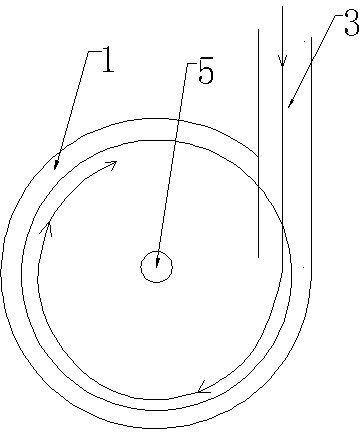

[0061] The multi-magnetic field whirl tiny oxygen bubble generator includes a high-pressure air-water mixing chamber 1 and a rotating compression chamber 2. The high-pressure air-water mixing chamber 1 is cylindrical in shape, with one end closed and the other end communicating with the rotating compression chamber 2. The tangent of the water mixing chamber 1 is provided with a pressurized air-water inlet 3, and the inner wall of the rotary compression chamber 2 is provided with a magnetic sheet layer 4, such as a magnet layer or a magnetic steel layer. One end of the rotary compression chamber 2 communicates with the high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com