Aluminum-magnesium alloy cutting fluid

A technology of aluminum-magnesium alloy and cutting fluid, which is applied in the direction of lubricating composition and petroleum industry, etc., can solve the problems of insufficient lubricating performance, high-temperature easy combustion of magnesium chips, insufficient anti-rust and anti-corrosion performance, etc., and achieve excellent lubricating and anti-wear performance, Effect of preventing corrosion and rust, excellent rust and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

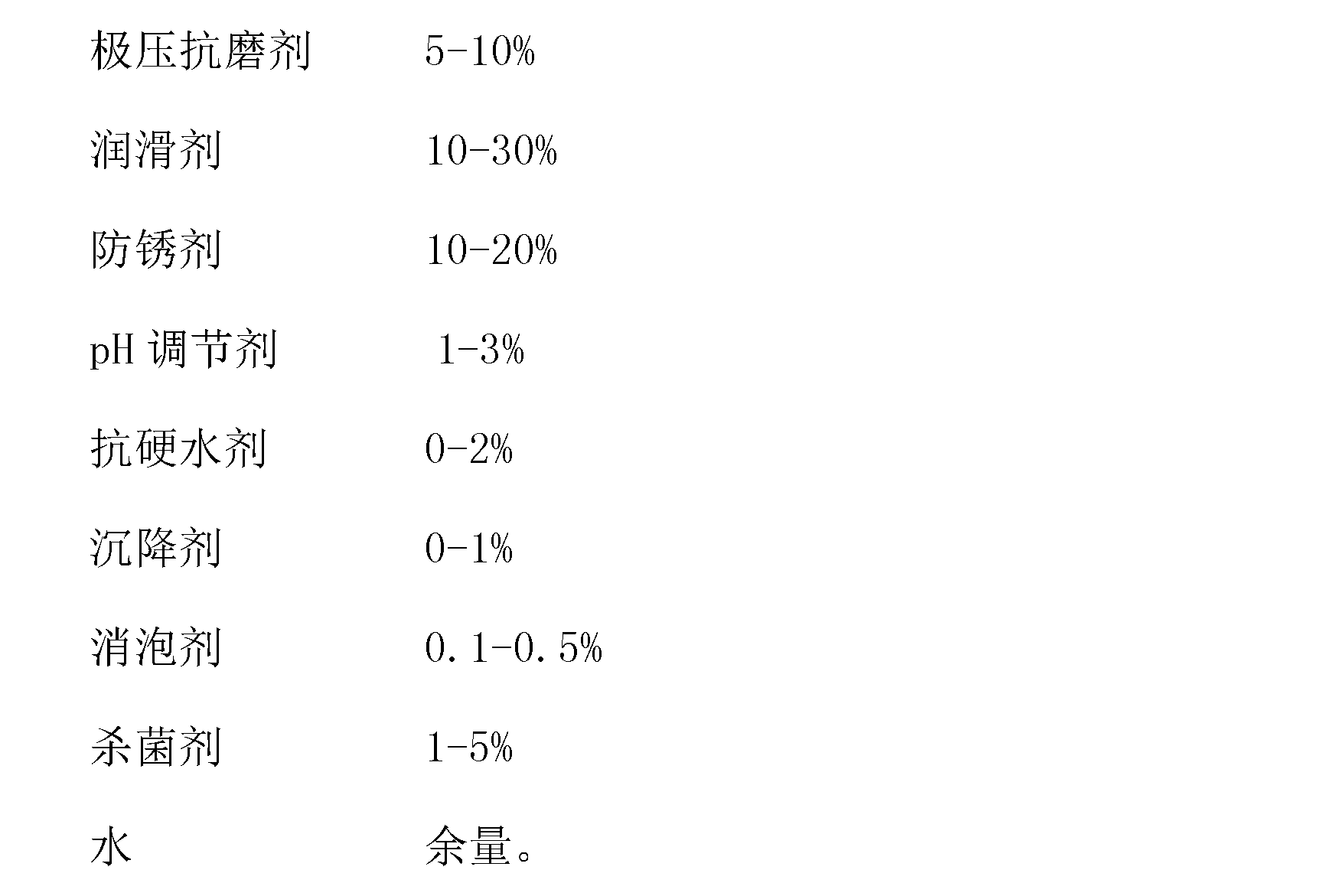

Method used

Image

Examples

Embodiment 1

[0018] The raw materials and weight components used in this example are as follows: extreme pressure antiwear agent borate 8%, lubricant polyether 20%, rust inhibitor long-chain organic carboxylic acid 10%, pH regulator sodium carbonate 2%, anti-corrosion agent Hard water agent disodium EDTA-2Na 1%, sedimentation agent polycation quaternary ammonium salt 0.5%, defoamer silicone 0.5%, bactericide hexahydrotriazine 1%, and the balance is water.

[0019] The preparation method and steps are as follows:

[0020] First, in the mixing tank filled with sufficient solvent water, after starting the mixer, add the additives in sequence according to the proportion, and the interval between additions should be greater than 5 minutes. After all the raw materials are added, continue to stir for 20 minutes, and take a small amount of samples into the beaker Observe with the naked eye in the bright place, after passing the inspection, it can be discharged from the filling barrel.

Embodiment 2

[0022] The raw materials and weight components used in this embodiment are as follows: extreme pressure antiwear agent borate 10%, lubricant polyethylene glycol 10%, rust inhibitor long-chain organic carboxylic acid 15%, pH regulator sodium hydroxide 1 %, anti-hard water agent ether carboxylic acid 1%, sedimentation agent polycation quaternary ammonium salt 0.5%, defoamer silicone 0.3%, bactericide hexahydrotriazine 2%, and the balance is water.

[0023] The preparation method and steps are as follows:

[0024] First, in the mixing tank filled with sufficient solvent water, after starting the mixer, add the additives in sequence according to the proportion, and the interval between additions should be greater than 5 minutes. After all the raw materials are added, continue to stir for 20 minutes, and take a small amount of samples into the beaker Observe with the naked eye in the bright place, after passing the inspection, it can be discharged from the filling barrel.

Embodiment 3

[0026] The raw materials and weight components used in this example are as follows: extreme pressure antiwear agent borate 5%, lubricant polyethylene glycol 15%, rust inhibitor long-chain organic carboxylate 20%, pH regulator sodium hydroxide 1.5%, anti-hard water agent ether carboxylic acid 2%, sedimentation agent polycation quaternary ammonium salt 0.7%, defoamer silicone 0.3%, bactericide hexahydrotriazine 4%, the balance is water

[0027] The preparation method and steps are as follows:

[0028] First, in the mixing tank filled with sufficient solvent water, after starting the mixer, add the additives in sequence according to the proportion, and the interval between additions should be greater than 5 minutes. After all the raw materials are added, continue to stir for 20 minutes, and take a small amount of samples into the beaker Observe with the naked eye in the bright place, after passing the inspection, it can be discharged from the filling barrel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com