Bridge deck continuous device applied to beam bridge and bridge deck continuous method

A bridge deck pavement and installation surface technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve problems affecting the durability of cover beam concrete, bridge driving flatness damage, concrete cracking, etc., to achieve delay and concrete cracking, Improve driving comfort and reduce concrete cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

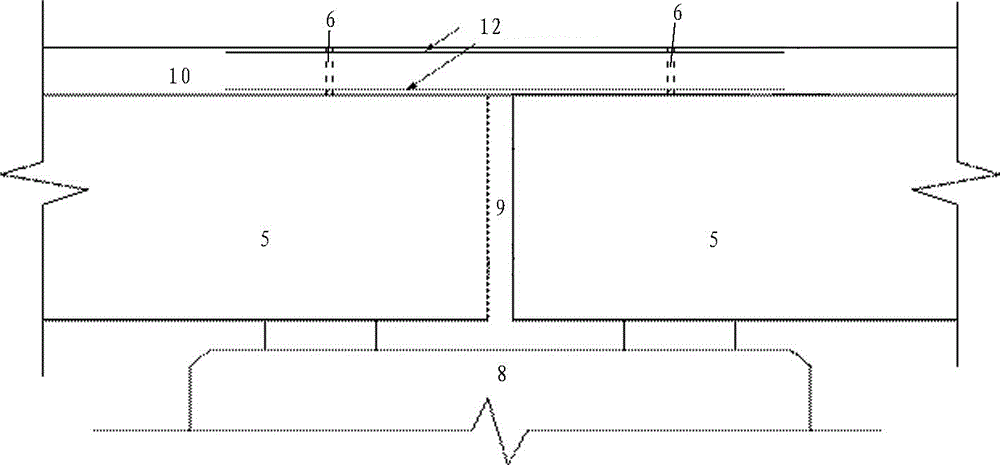

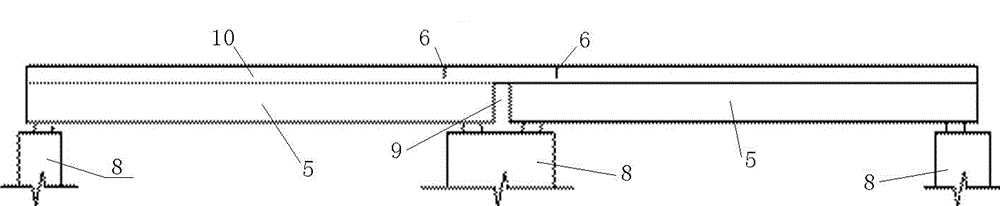

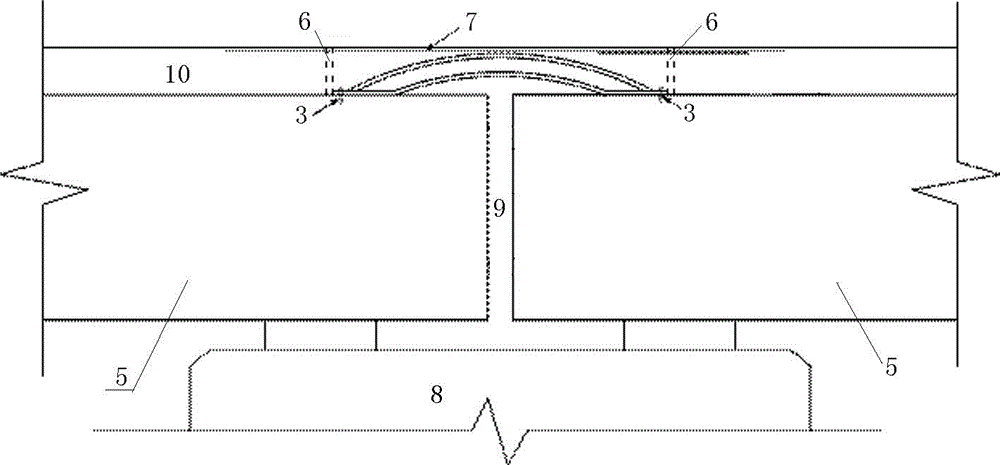

[0021] Refer to attached picture.

[0022] The invention introduces the arch structure in the bridge structure into the continuous part of the bridge deck, and disperses the stress concentration phenomenon of the concrete at this part. The bridge deck continuous device of the present invention includes an arch structure 1, and the two sides of the arch structure 1 are provided with mounting surfaces 11 for connecting with the bridge deck beam body. For vehicle loads, steel plates with a thickness of 9mm are used as the device material. Bolt holes 3 are provided on the mounting surface 11 . The upper part of the arched structure 1 is provided with I-beam-shaped ribs 2 at a certain distance along the width direction. On the one hand, the bearing capacity of the device can be improved, and on the other hand, the tensile stress borne by the concrete can be better dispersed.

[0023] Bridge deck continuous method of the present invention comprises the following steps:

[0024] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com