RPW (ranked position weight) process for treating high fill slope

A high fill slope technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of treatment engineering failure, complex construction technology, poor self-stabilization ability, etc., to achieve strong pertinence, simple process, and reliability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

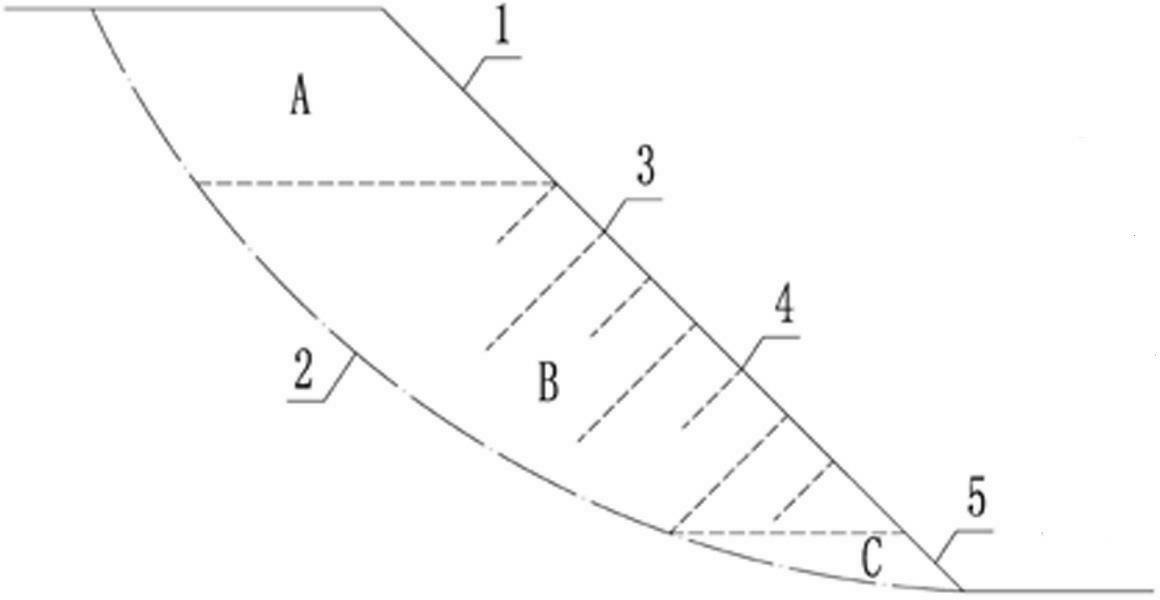

[0017] root tree figure 1 , figure 2 Shown: a kind of RPW method technology used to deal with high fill slope, the specific implementation steps are as follows:

[0018] (1) Surface soil replacement and filling, rolling and compacting: replace the filling soil within the depth range of 3.0m below the top of the slope with notoginseng ash soil (quicklime: cohesive soil = 3:7), and compact it with an 18t vibratory road roller for 4 to 6 times , the rolling density is not less than 90%;

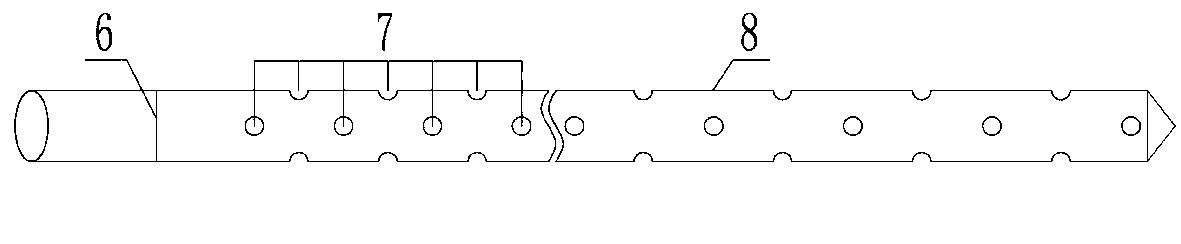

[0019] (2) Pressure grouting in the middle slope: Use steel flower pipes to perform pressure grouting on the filling soil within the range of 3.0m to 1.2 times the critical infiltration depth of atmospheric rainfall below the top of the slope to form a hardened layer on the slope;

[0020] (3) Tamping foot protectors on the lower slope: Use N63.5 heavy hammer to manually tamp the filling slope below the top of the slope beyond the range of 1.2 times the critical infiltration depth of atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com