Process for preparing diamond geological coring bit

A core drill bit and preparation technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of low compaction density, short service life, easy fracture of alloys, etc., and achieve the effect of increasing compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

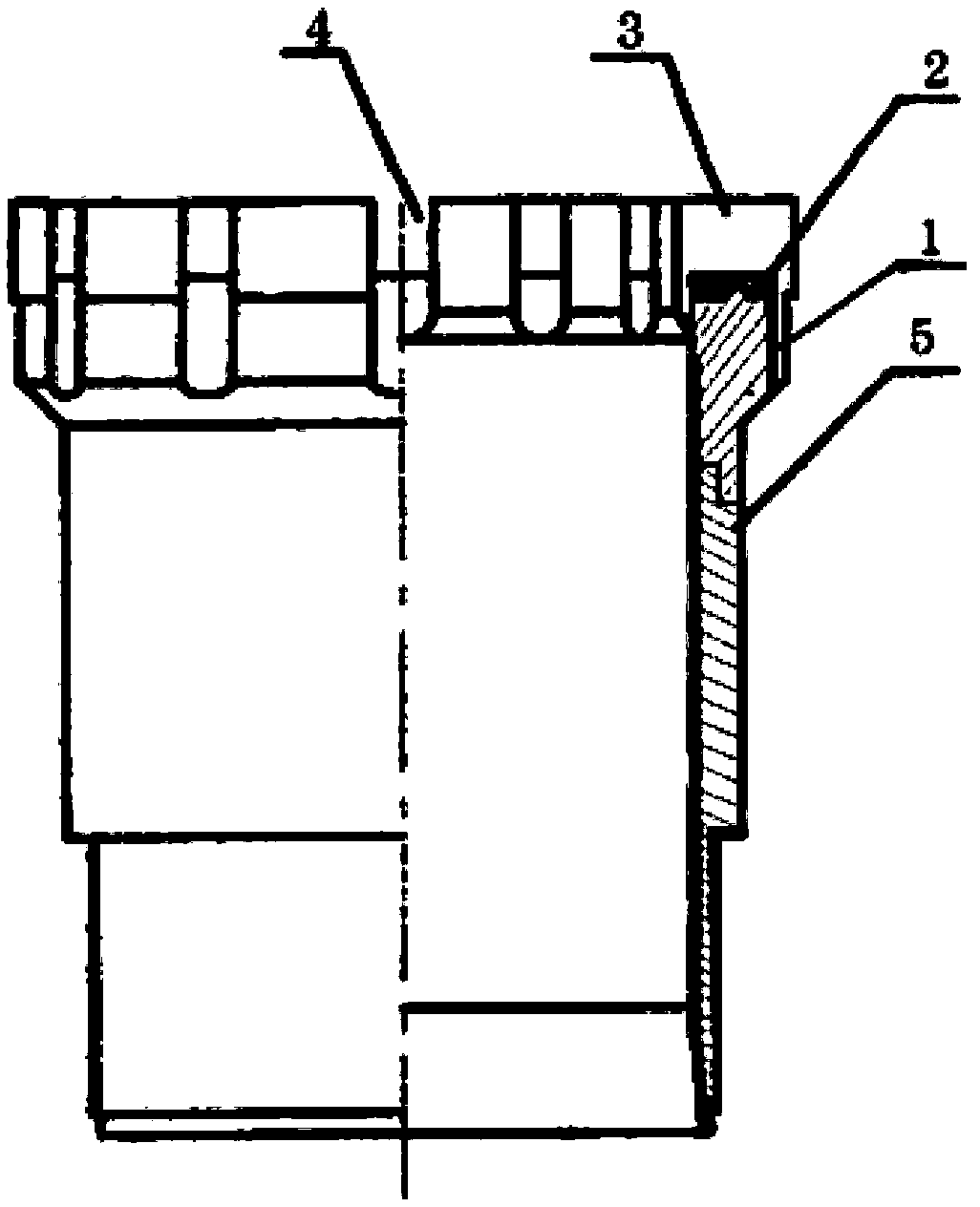

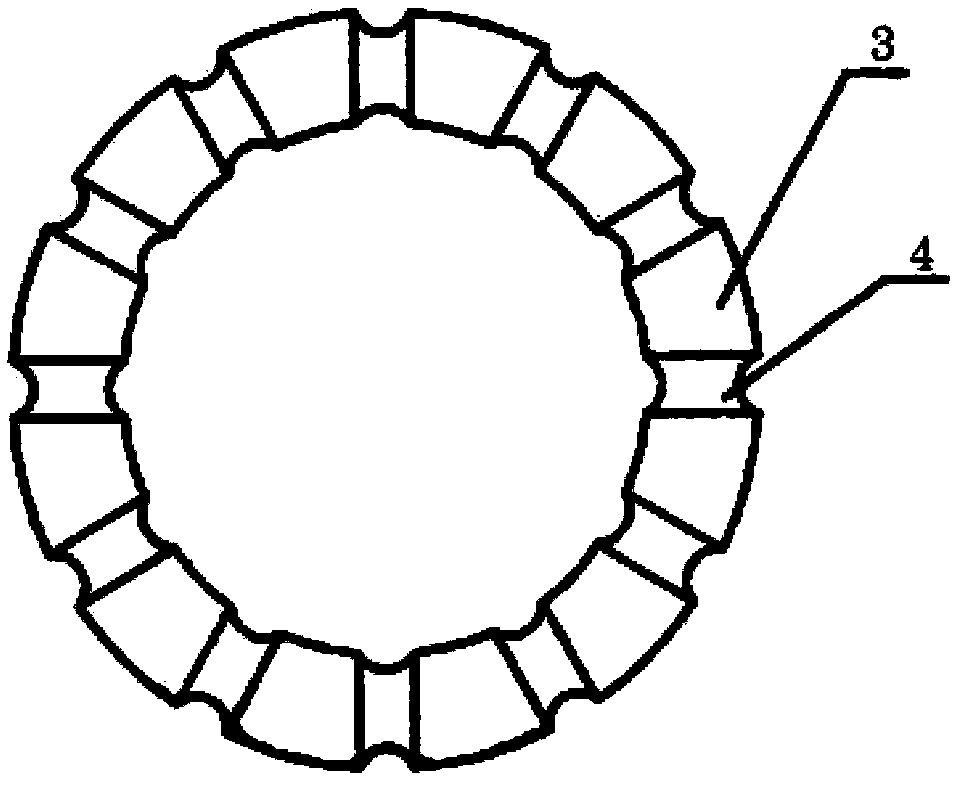

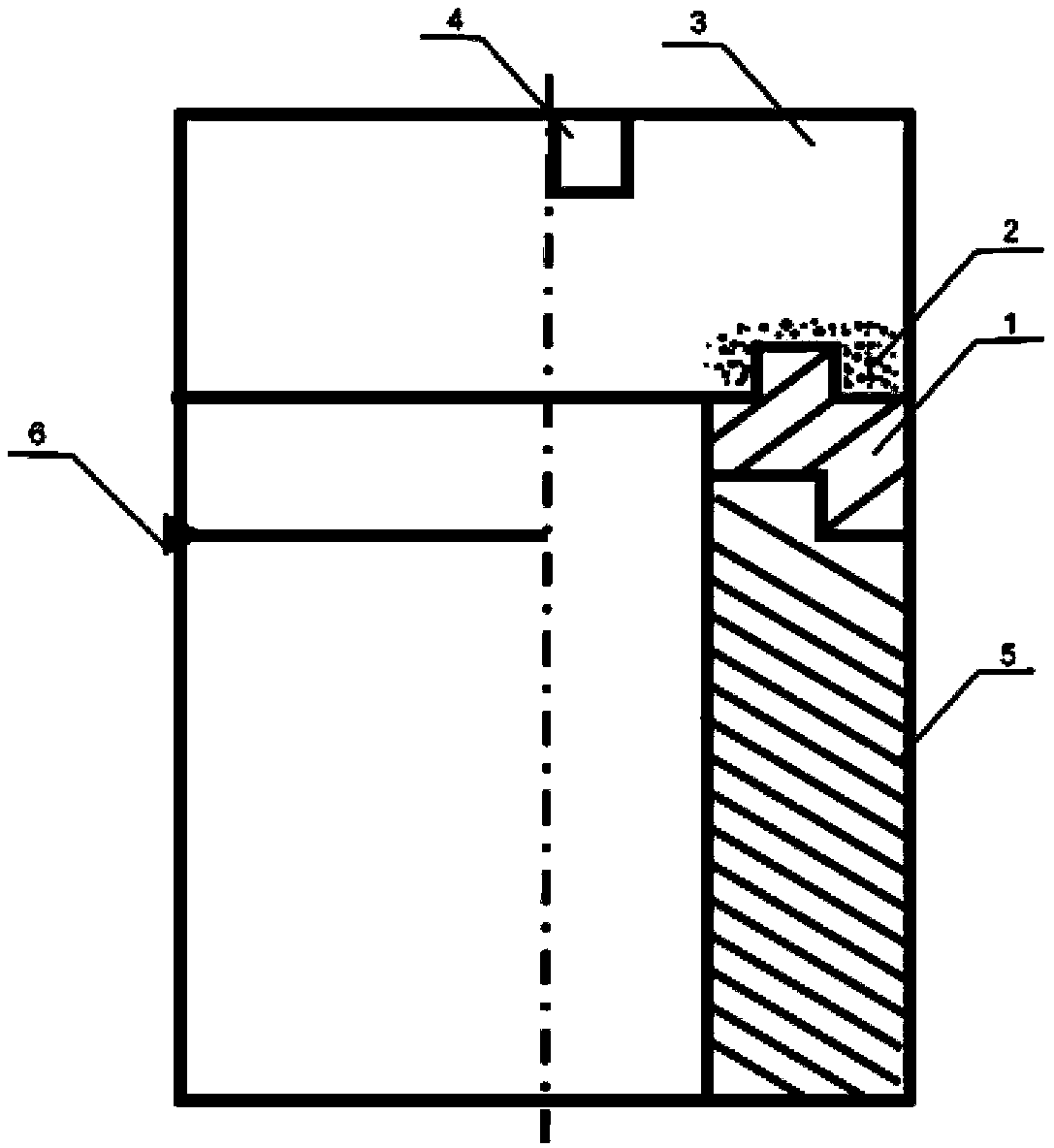

[0024] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0025] The invention provides a preparation process of a diamond geological core bit, which is characterized in that it is realized in the following steps:

[0026] (1) Clean the graphite mold, match the mold, pay attention to the fit gap between the steel body of the drill bit and the graphite inner and outer molds; first install the nozzle material in the mold, and then install the mixture of diamond and powder;

[0027] (2) Install welding layer powder;

[0028] (3) Insert the working steel body;

[0029] (4) Put it into a resistance sintering furnace to be fired, and press it up and down, and the resistance area is 1 / 3 of the entire mold area;

[0030] (5) Heating, when the temperature rises to 720-780°C, add 1 / 3 of the total pressure of 12-18Mpa;

[0031] (6) When the temperature rises to 850-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com