Dual-fuel electric control monomer ejector

An injector, dual-fuel technology, applied in fuel injection devices, charging systems, machines/engines, etc., can solve the problems of limited application scope, reduced economy, and plastic deformation of dual-fuel diesel engines, and achieve improved injection performance and mist. chemical effect, improve emissions and economy, avoid the effect of incomplete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

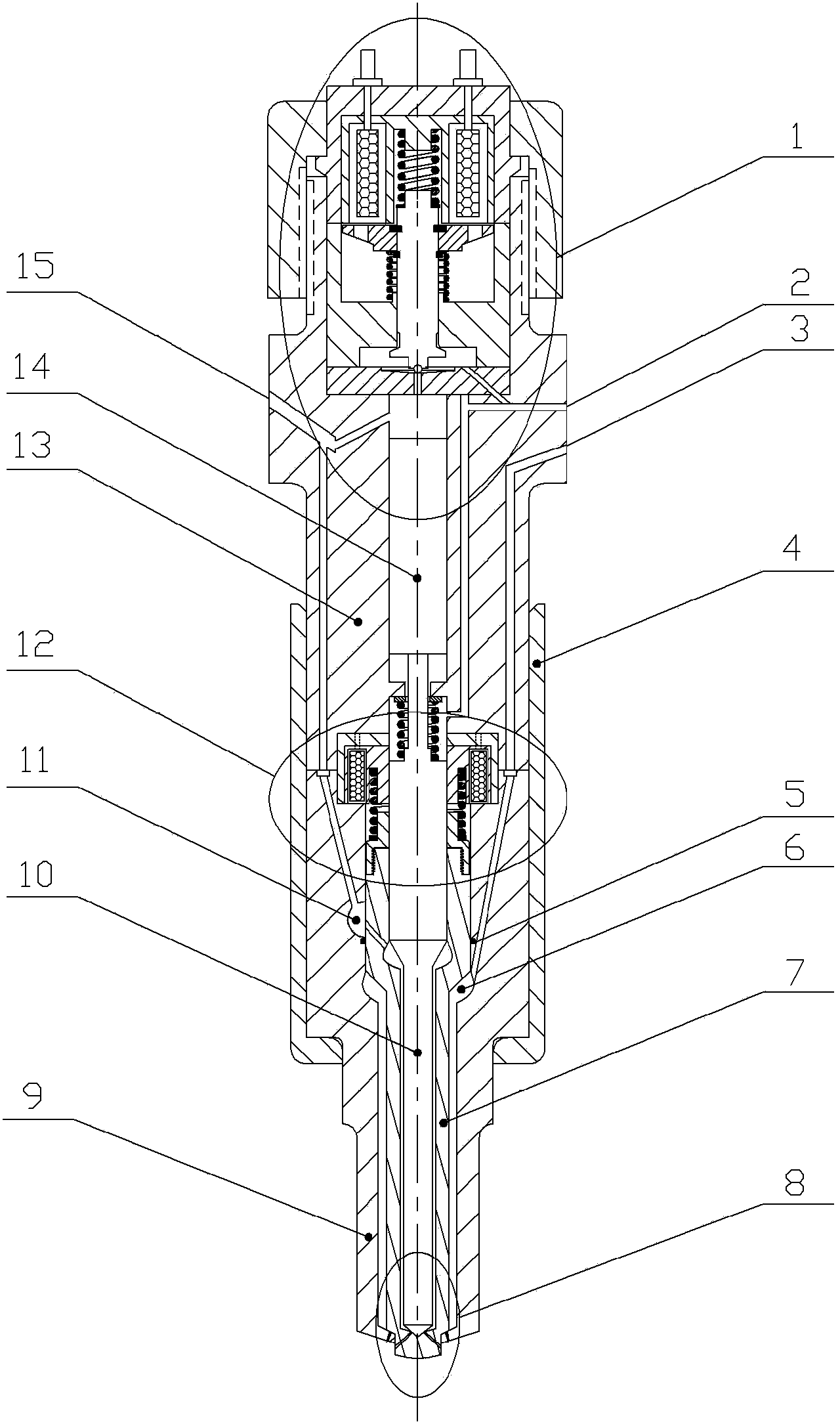

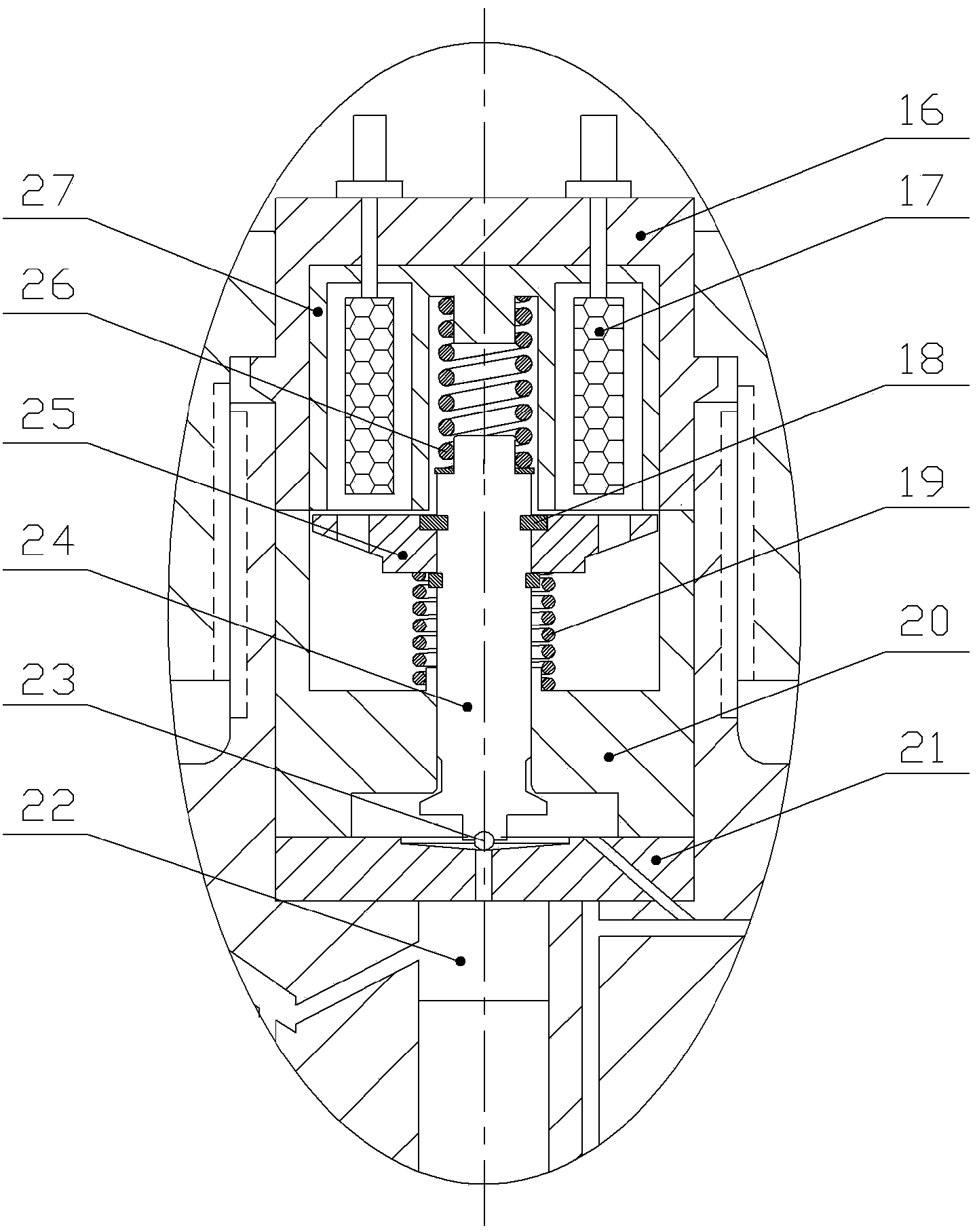

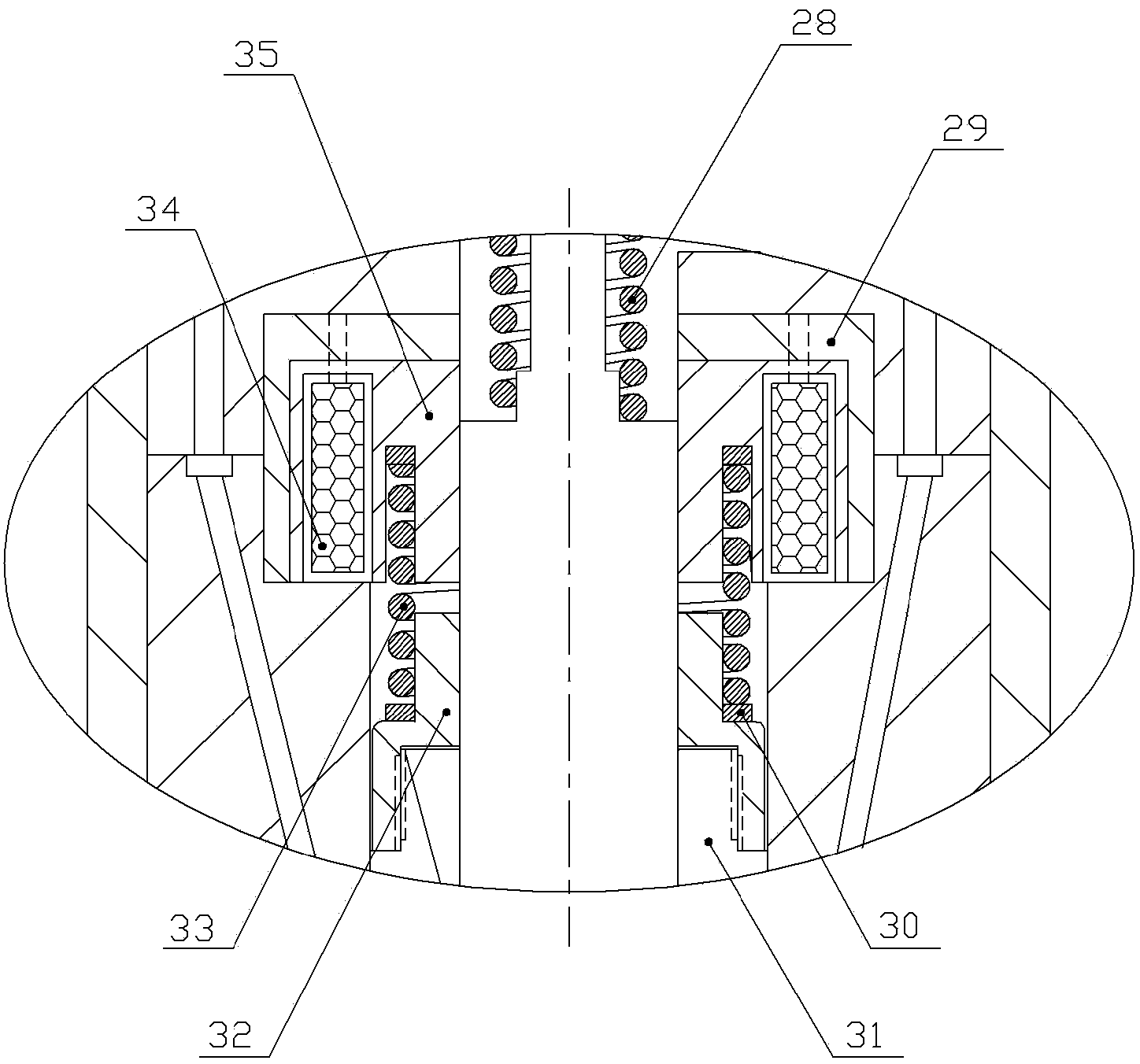

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] combine Figure 1~4 , the dual-fuel electronically controlled unit injector of the present invention mainly includes a control diesel solenoid valve 1, an oil drain port 2, a natural gas inlet 3, a tight cap 4, a sliding sealing ring 5, a sliding needle valve sleeve 7, a nozzle 9, a needle valve 10. Control natural gas solenoid valve 12, injector body 13, control piston 14 and diesel inlet 15, etc., characterized in that: diesel inlet 15 is connected with high-pressure oil pipe, and diesel solenoid valve 1 is controlled by power on and off to control armature 25, pulling control The spool 24 realizes the discharge of the diesel in the control chamber 22, so that the needle valve 10 is lifted to realize the injection of the diesel. The natural gas inlet 3 is connected with the natural gas pipeline, and the natural gas electromagnetic valve 12 controls the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com