Method for controlling synchronous impact of clutch

A control method and synchronous shock technology, applied in clutches, electric clutches, non-mechanical drive clutches, etc., to achieve the effect of strong real-time performance, simple control method and reduced shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

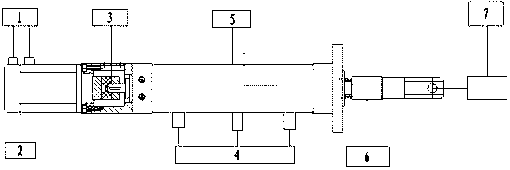

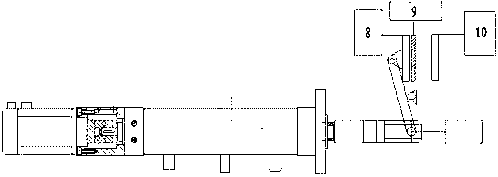

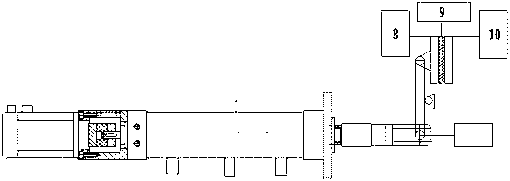

[0030] The present invention is further elaborated below in conjunction with accompanying drawing, the present invention has adopted electric automatic clutch. as attached figure 1As shown, the electric automatic clutch system is composed of servo motors, couplings, ball screws and other mechanisms, and is equipped with encoders, position sensors, and limit sensors. In the present invention, a 16-bit microcontroller of the FreeScale MC9S12DT128 type sends out pulse signals to control the motion of the servo motor, and the rotation of the servo motor drives the ball screw to convert the rotary motion into a forward and backward linear motion. Through the linear motion of the ball screw, the release lever of the clutch is pushed to realize the separation and combination of the clutch. When the single-chip microcomputer sends out a pulse, it also sends out a high level or a low level to control the rotation direction of the servo motor and realize the forward and backward of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com