Lateral sealing composite variable speed drive belt

A technology of variable-speed transmission and seals, applied in the direction of transmission belts, belts/chains/gears, mechanical equipment, etc., can solve the problems of low transmission efficiency, high torque, transmission power loss of transmission belts, etc., to improve fuel efficiency, improve service life, The effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

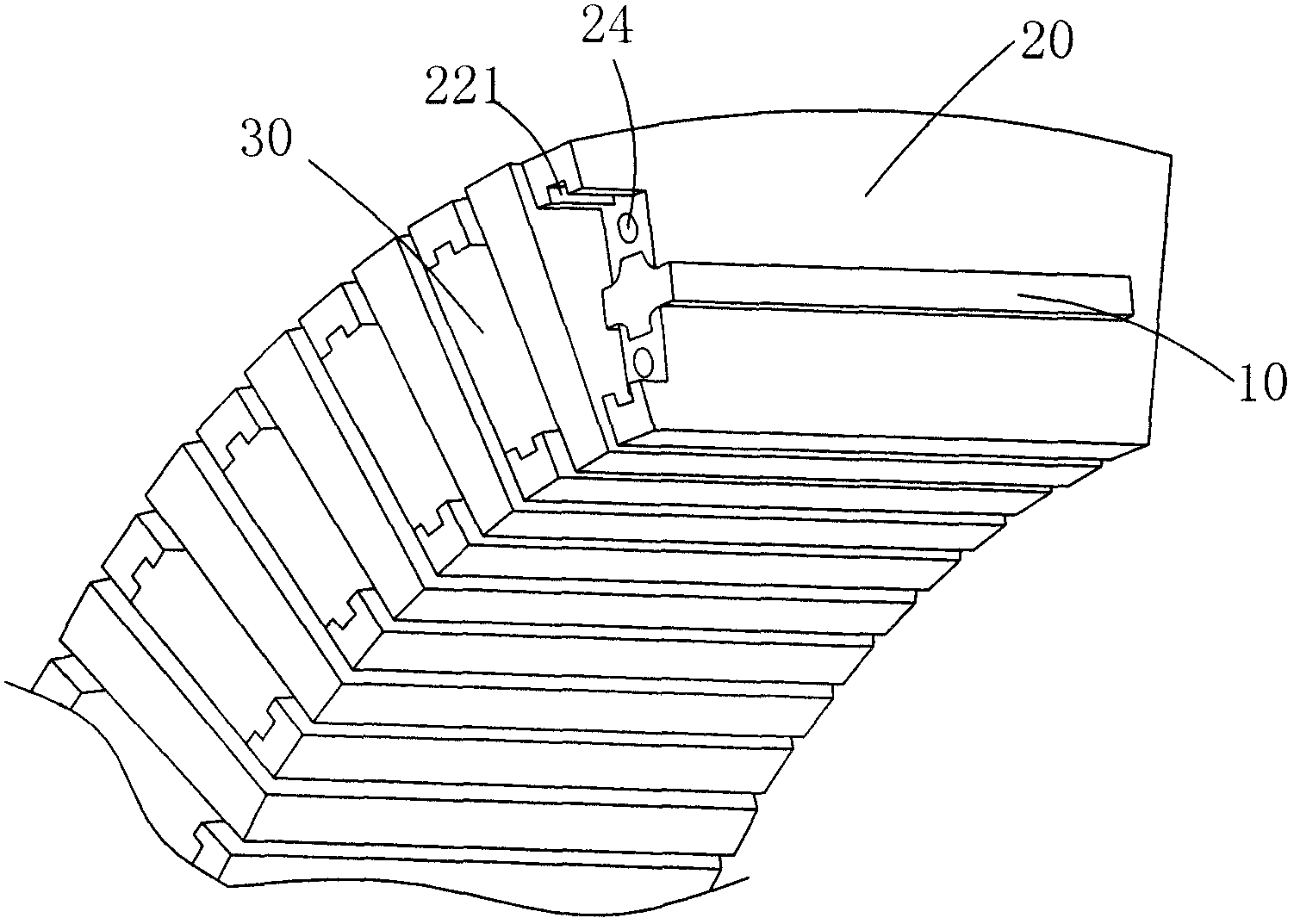

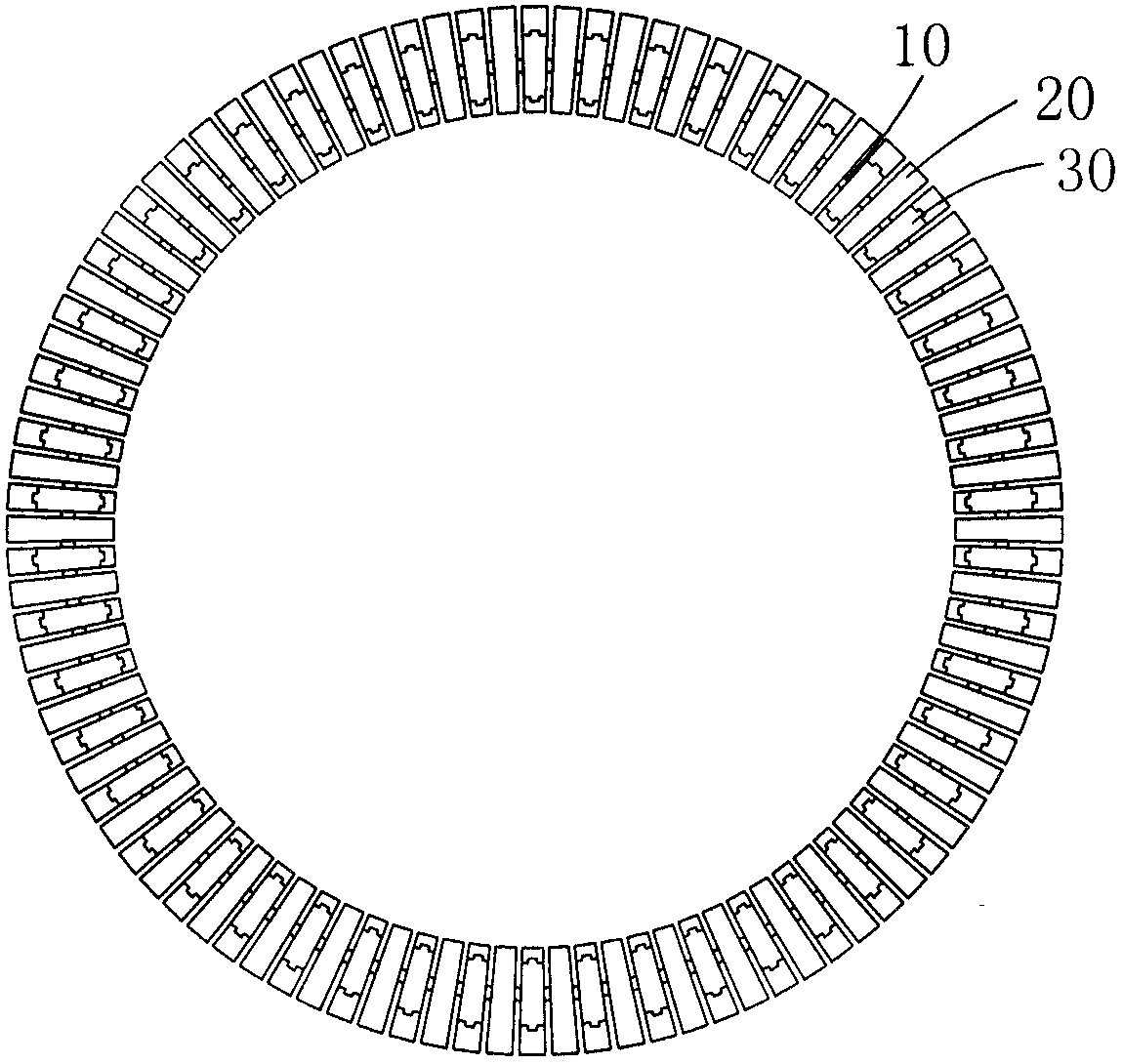

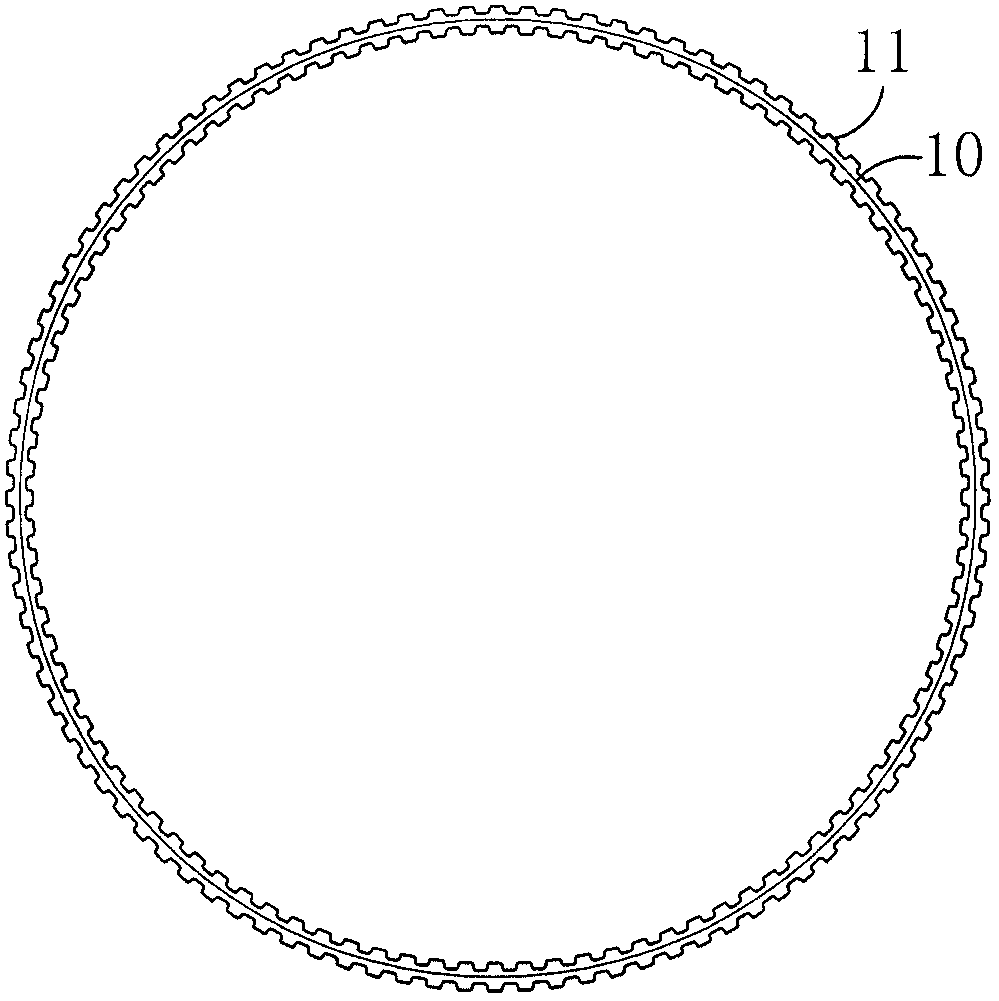

[0024] Example 1, see Figure 1 to Figure 6 Shown: a laterally sealed composite speed change transmission belt, including a belt body 10 with teeth 11 , a transverse reinforcing member 20 and a lateral sealing member 30 . The front view of the transverse reinforcement 20 is fan-shaped, and its included angle ranges from 20° to 60°. In common cases, we choose 26°; the side view of the transverse reinforcement 20 is fan-shaped, and its included angle ranges from 3° to 12°, in common cases we choose 3° as the best. The angle of the transverse reinforcement 20 is determined according to the tooth shape of the belt teeth 11 on the belt body 10 , and the above-mentioned included angle is selected as a common belt tooth shape. The top of the transverse reinforcement 20 is in the shape of an arc, which can effectively enhance the transverse rigidity of the transverse reinforcement 20. The chord height of the arch is generally between 0.5 and 3 mm, and 1.5 mm is preferred in common ca...

Embodiment 2

[0026] Example 2, see Figure 7 and Figure 8 As shown: the basic structure and principle of embodiment 2 are the same as that of embodiment 1, the difference is that the above-mentioned snap-in mechanism is: a snap-in block 222 is set on the sealing opening 22 of the transverse reinforcement 20, and in the lateral direction The positioning opening 311 is set on the sealing member 30 to achieve the purpose of positioning; then the above-mentioned joint mechanism is as follows: set the plug-in block 241 on the transverse reinforcement 20, set the receiving hole 321 on the lateral sealing member 30, and then use ultrasonic welding to To achieve the purpose of joining and fixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com