Top-entry low-temperature fixed ball valve

A fixed ball valve, low temperature technology, applied in valve details, valve devices, cocks including cut-off devices, etc., can solve problems such as overpressure, and achieve low torque, reliable operation, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

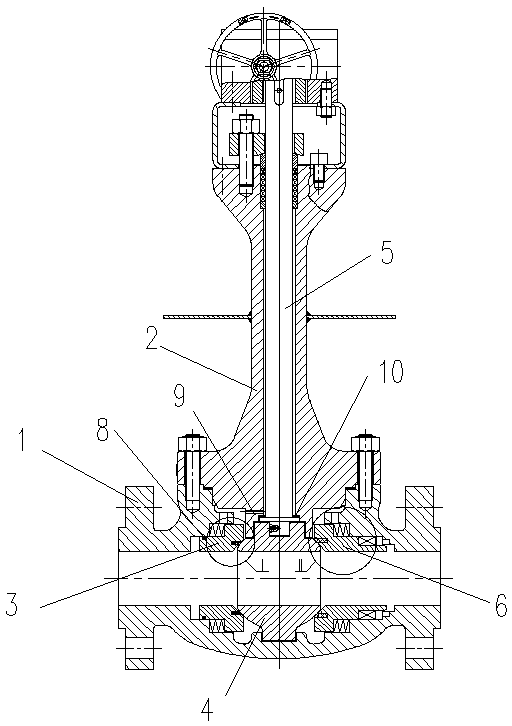

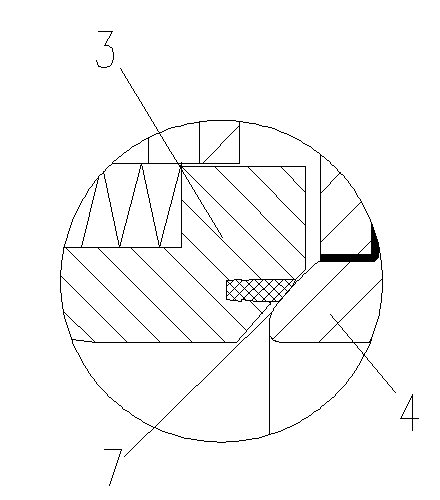

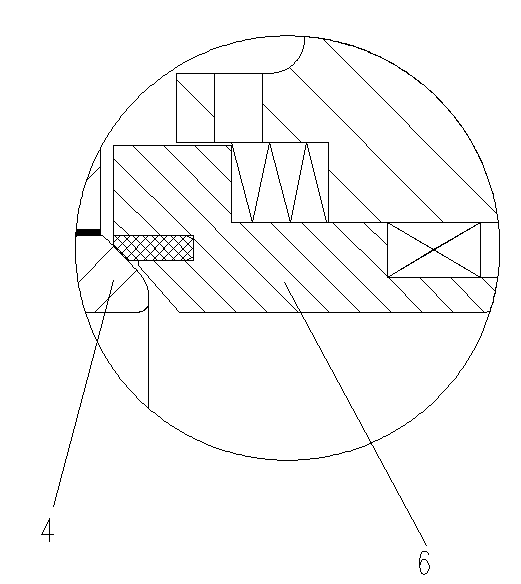

[0027] Example: see attached figure 1 to attach image 3 As shown, a top-entry low-temperature fixed ball valve includes a valve body 1, a valve seat arranged in the valve body 1, a ball 4 cooperating and sealing with the valve seat, a valve stem 5 connected with the ball 4, and a valve stem 5 sleeved on the valve stem 5. The valve cover 2 which is sealed and fixed with the valve body, the valve body 1, the valve seat, and the through holes on the ball 4 are connected to form a fluid passage. The valve seat includes an upstream valve seat 3 and a downstream valve seat 6. The upstream valve seat 3 There is a communication groove 7 at the junction with the sphere, the communication groove 7 communicates the fluid channel and the valve cavity, and a graphite fire ring 8 is provided between the upstream valve seat 3 and the valve body 1; It is equipped with a sealing structure composed of a universal sealing ring. The upper part of the bonnet 2 and the valve stem 5 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com