Backlight module

A backlight module and backplane technology, applied in the field of backlight modules, can solve the problems of insufficient glass substrate support, light leakage, large local stress, etc., and achieve the effect of improving the optical quality, increasing the supporting area, and preventing light leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

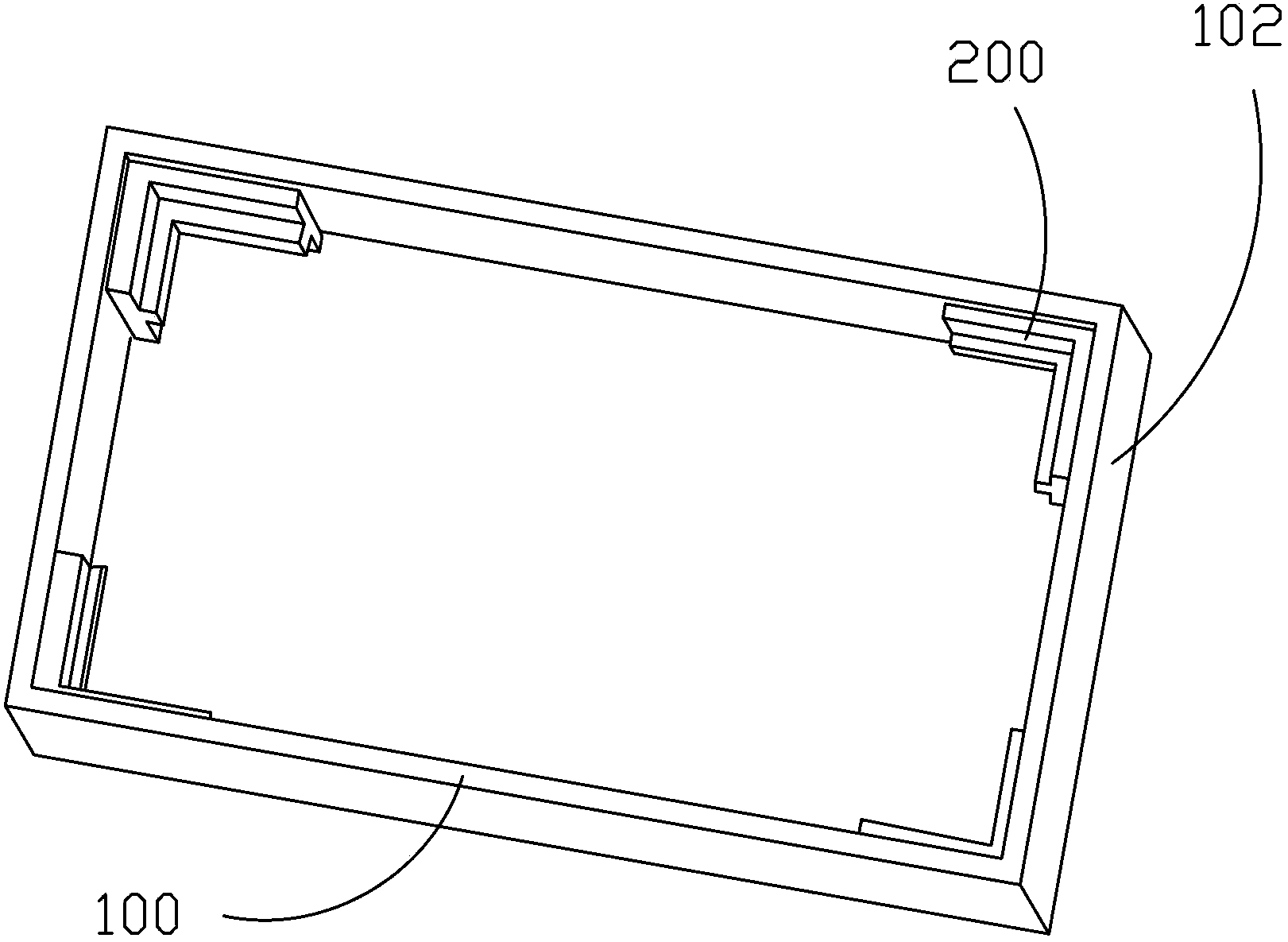

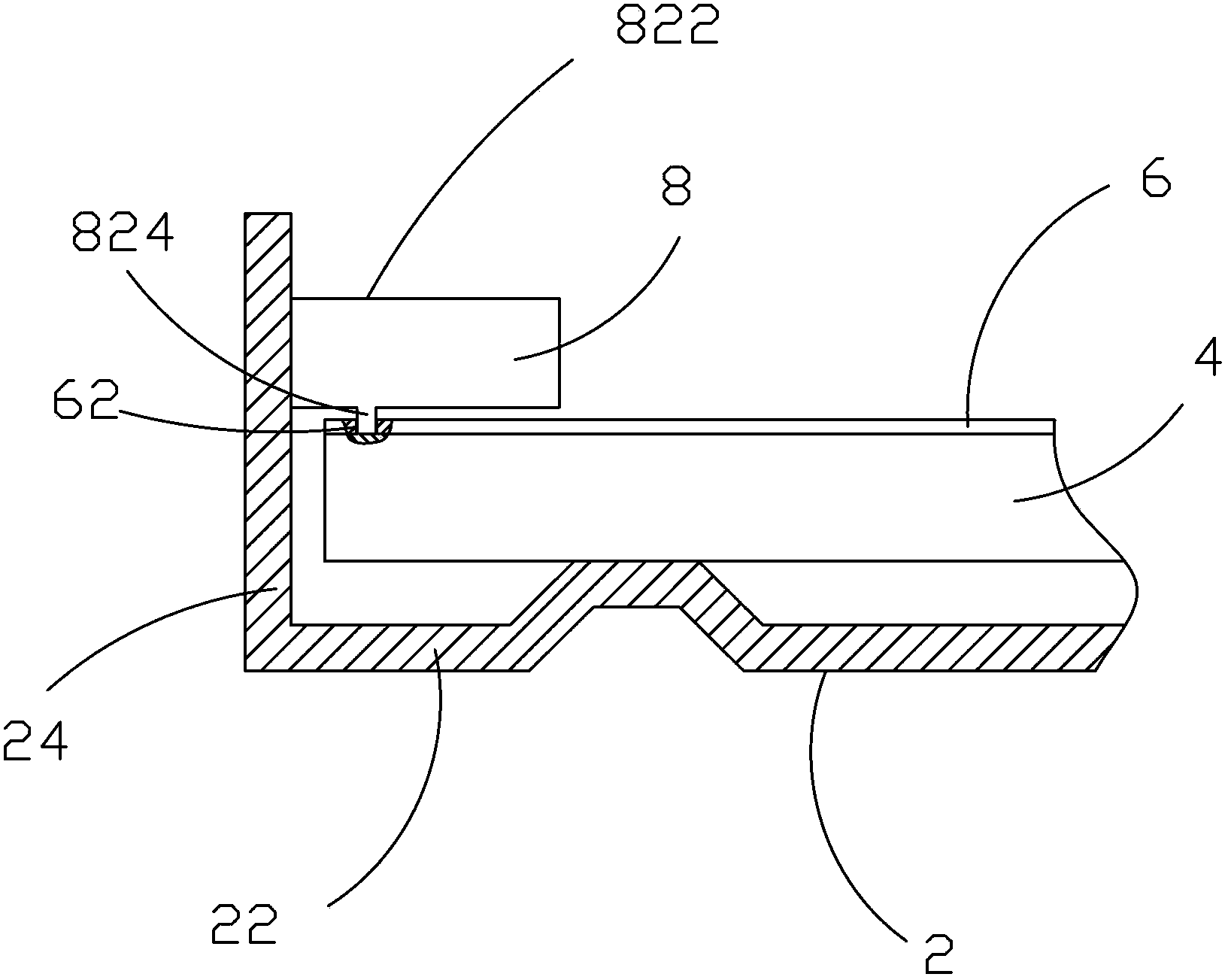

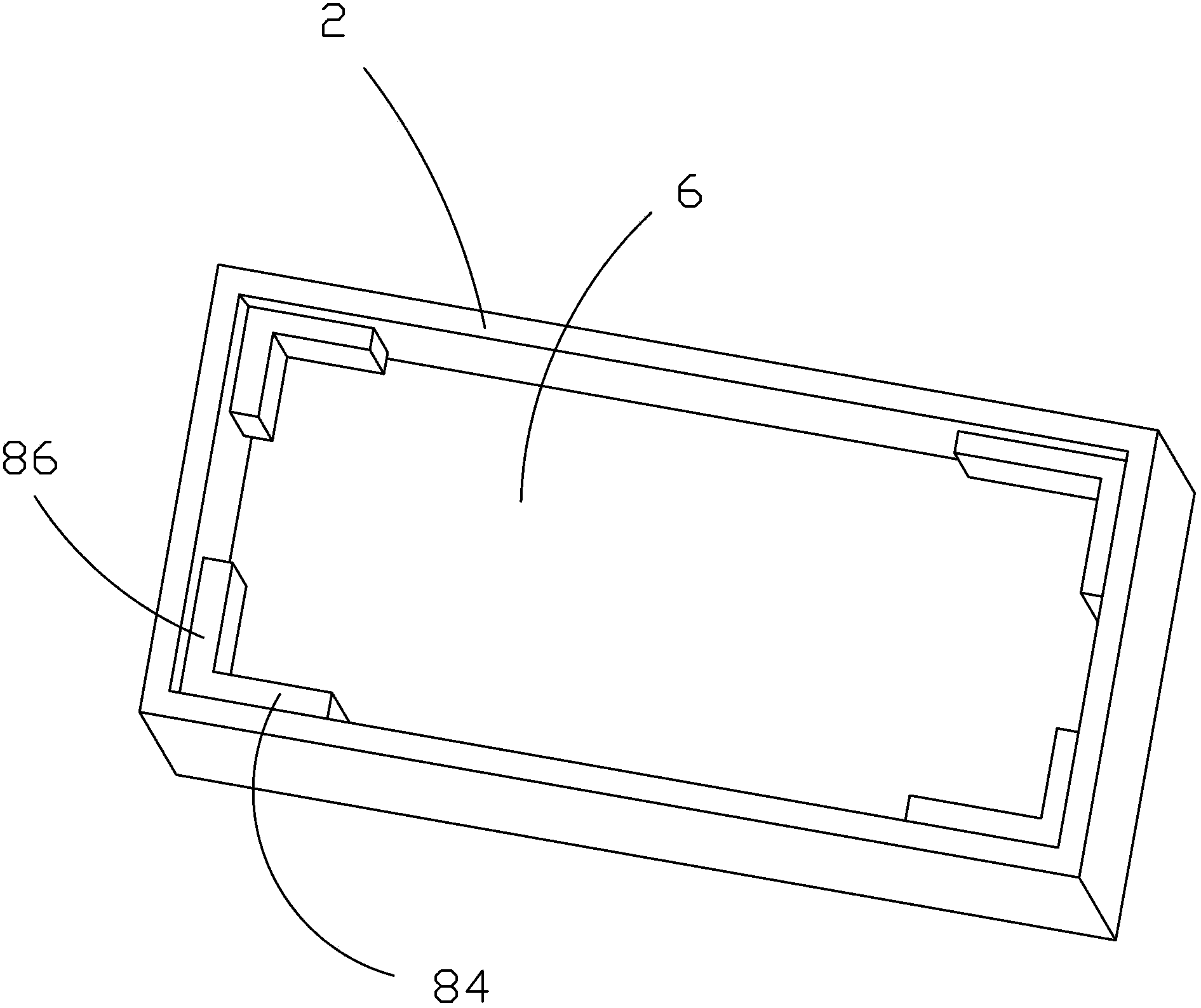

[0024] refer to figure 2 and image 3 , the present invention provides a backlight module, comprising: a backplane 2, a backlight source (not shown) arranged in the backplane 2, a light guide plate 4 arranged in the backplane 2, an optical The diaphragm set 6 and the split-type plastic frame 8 arranged in the back plate 2 , the split-type plastic frame 8 includes several separately arranged corner pieces 82 , which are respectively located on the optical film set 6 .

[0025] The backboard 2 includes a bottom board 22 and a plurality of side boards 24 connected to the bottom board 22 , and the corner pieces 82 are respectively installed on the side boards 24 of the back board 2 by gluing or screwing. Preferably, the corner pieces 82 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com